Brake master cylinder assembly line of a vacuum booster

A technology of vacuum booster and brake master cylinder, applied in manufacturing tools, transportation and packaging, measuring/indicating equipment, etc., can solve the problems of insufficient safety protection measures, poor operation stability, low degree of automation, etc., and achieve photoelectric isolation. Reliable functions, stable and reliable equipment operation, flexible parameter settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

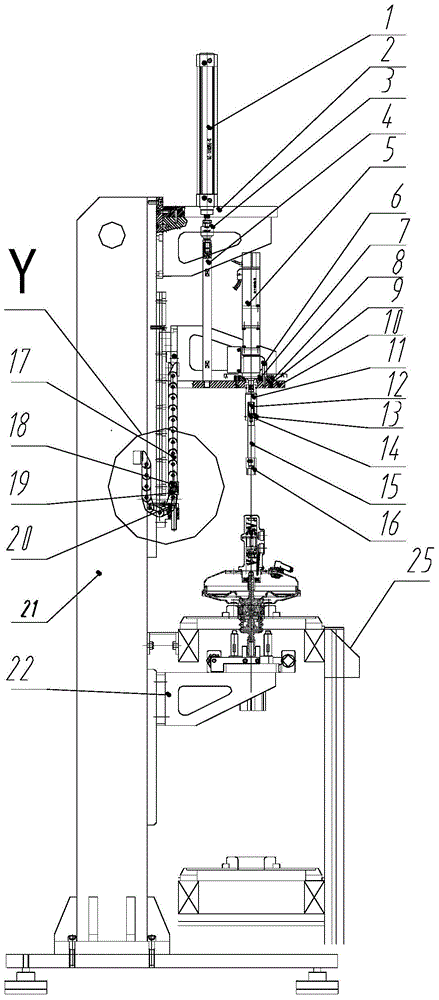

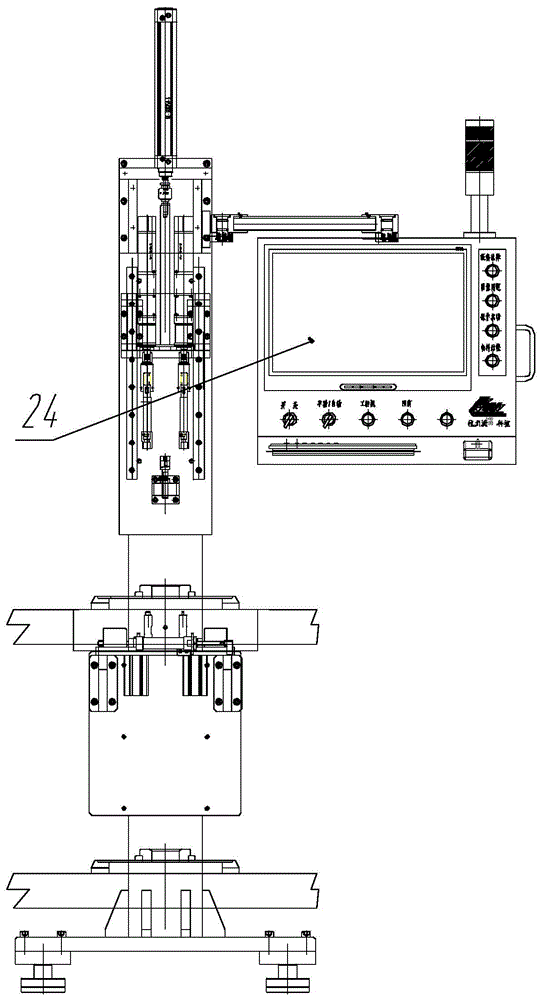

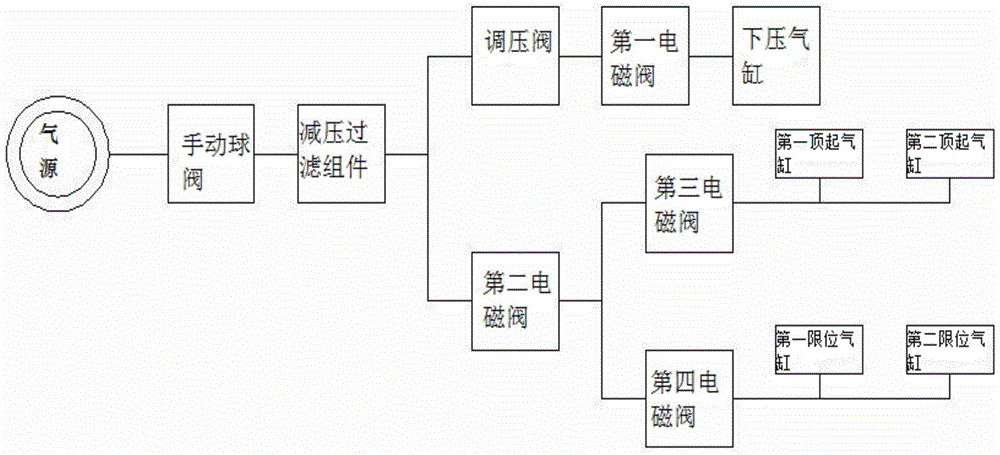

[0022] Embodiment: The brake master cylinder assembly line of the vacuum booster in this embodiment includes a mechanical transmission structure module, an automatic control module 24, and an air circuit system module;

[0023] Such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the lower pressure cylinder 1 of the mechanical transmission structure module is fixedly arranged on the lower pressure cylinder mounting bracket 2, and the lower pressure cylinder mounting bracket 2 is provided with a floating joint 3 connected with the cylinder connecting rod 4, and the left tightening machine 5 is installed on the left tightening machine On the mounting plate 7, the left tightening machine mounting plate 7 is connected with the sliding bracket 10, the left tightening machine mounting plate 7 is connected with a linear slide rail, and the right tightening machine mounting plate 23 is fixedly provided with a right tightening machine (not marked in the figure),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com