Thermal pyrolysis method for Fischer-Tropsch synthesis reaction wax residue

A Fischer-Tropsch synthesis and thermal cracking technology, used in the preparation of liquid hydrocarbon mixtures, petroleum industry and other directions, can solve the problems of boiler service life and high operating costs, and achieve the effects of satisfying environmental protection treatment, not easy to coke, and improving cracking and cracking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0028] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

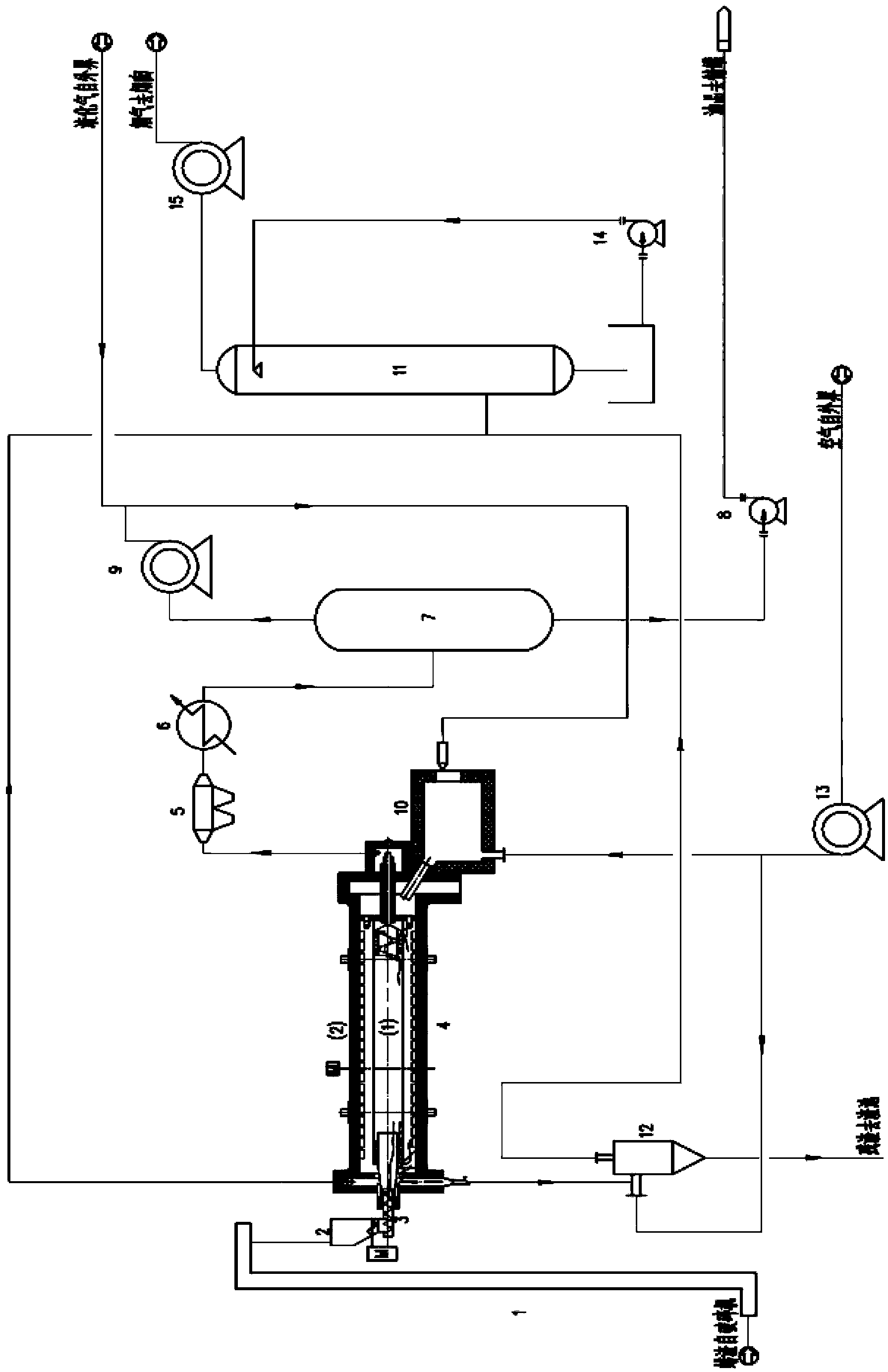

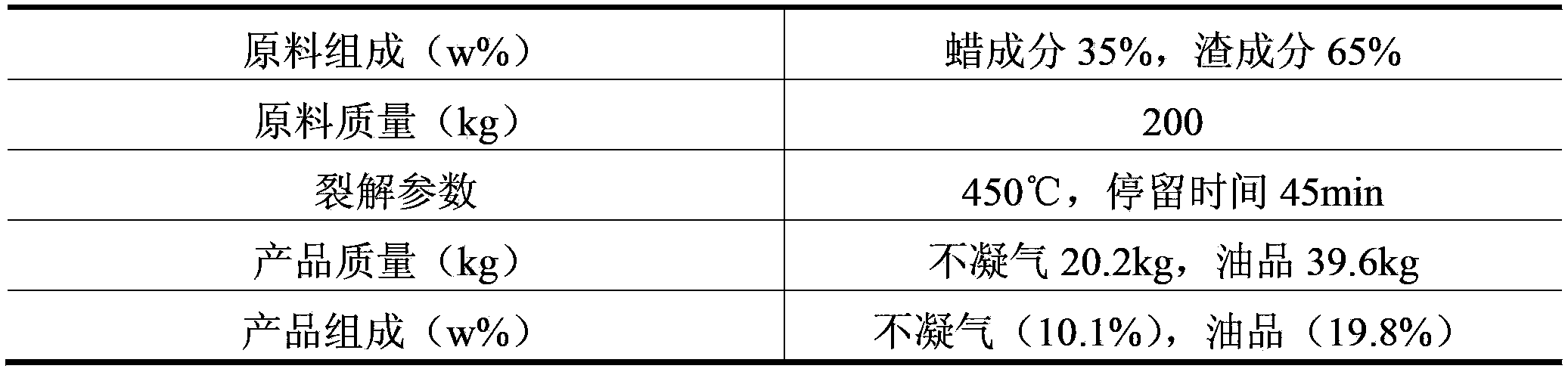

[0029] Such as figure 1 As shown, the present invention according to figure 1 The process shown in the process is to thermally crack and recover the Fischer-Tropsch synthesis reaction wax slag, break the Fischer-Tropsch synthesis reaction wax slag to be recovered into 5-10mm particles, and then send it to the silo 2 through the bucket elevator 1, and then enter The material screw 3 is sent into the inner cylinder of the horizontal rotary kiln 4, and is thermally cracked at a temperature of 450° C. for 45 minutes to obtain cracked oil gas and high-temperature residue. Wherein the horizontal rotary kiln 4 includes an inner cylinder and an outer cylinder sleeved outside the inner cylinder, and a lifting plate is arranged on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com