Method for detecting fracture splitting notch of connecting rod of automobile based on machine vision

A technology of automotive connecting rods and machine vision, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problem of not being able to accurately detect whether there is a cracking groove on the connecting rod and whether the connecting rod cracking groove is qualified, etc., to improve the interface And practicability, good stability and accuracy, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] 1. If there is no change between the model of the connecting rod detected this time and the model of the connecting rod detected last time, no system calibration is required. System calibration is required when the model of the connecting rod changes: plan the areas that need to be processed during the detection process for the image of the cracking tank on the left side of the connecting rod and the image of the cracking tank on the right side of the connecting rod, and record the starting and ending coordinates of the calibrated area , for use in detection.

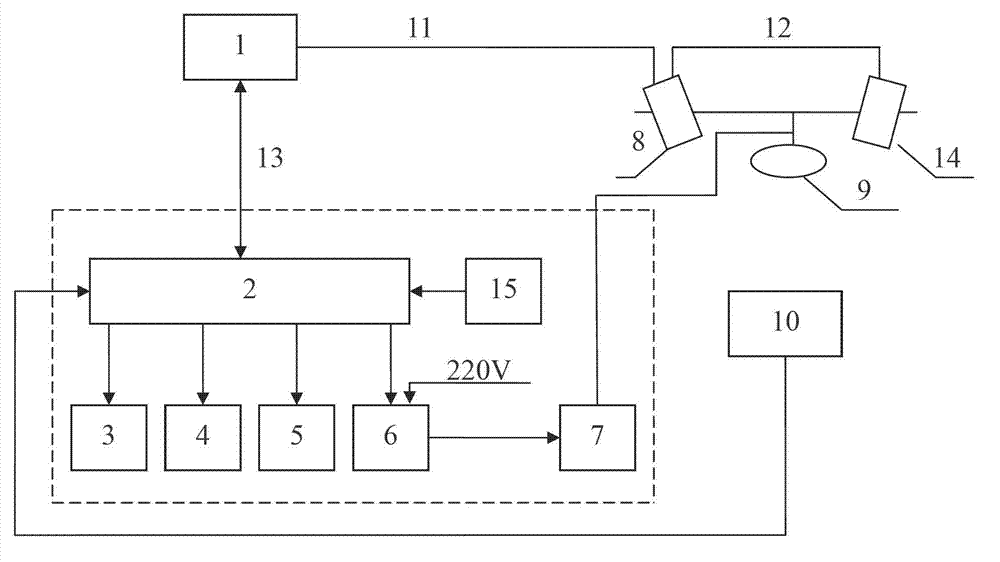

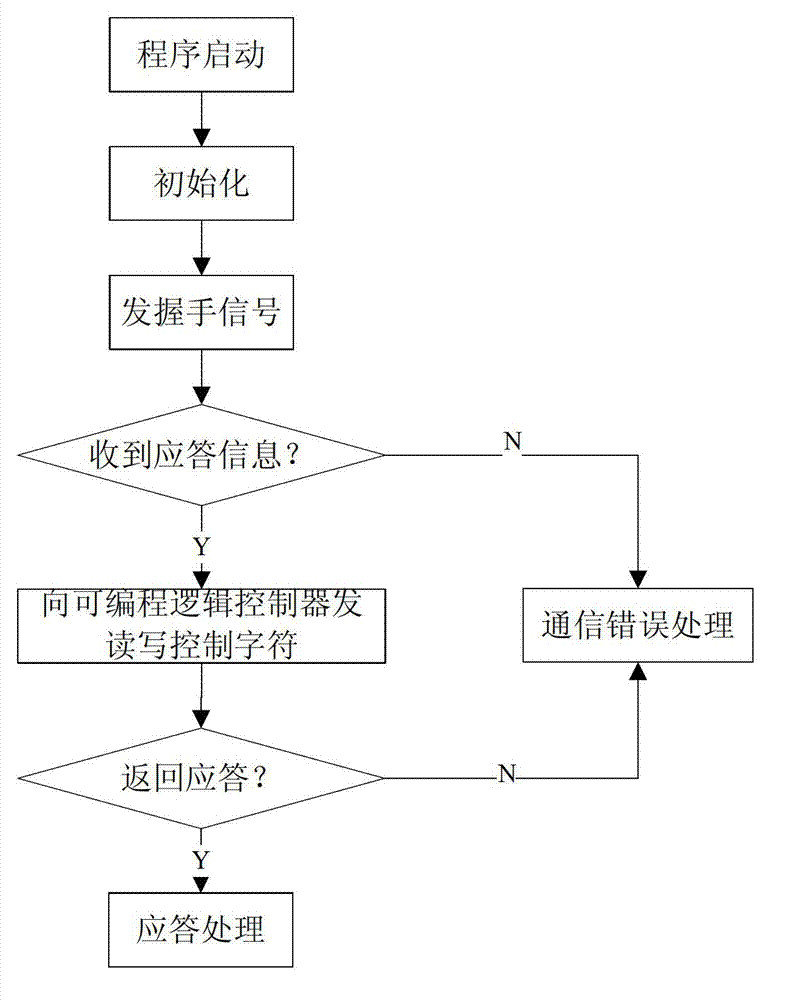

[0093] 2. In general detection, automatic detection will be selected. The detection process is that the computer 1 automatically obtains the signal trigger through the communication serial port with the programmable logic controller 2, and the image acquisition is performed through the No. 1 camera 8 and the No. 2 camera 14; Line 11 and No. 2 connection line 12 transmit the obtained connecting rod image through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com