Advanced treatment method of triethylamine salt-containing wastewater

A technology for advanced treatment of salty wastewater, applied in water/sewage treatment, natural water treatment, water/sewage multi-stage treatment, etc. It can solve the problems of evaporator tube and tube wall, so as to improve the treatment capacity and meet the requirements of environmental protection. Requirements, the effect of prolonging the normal use cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

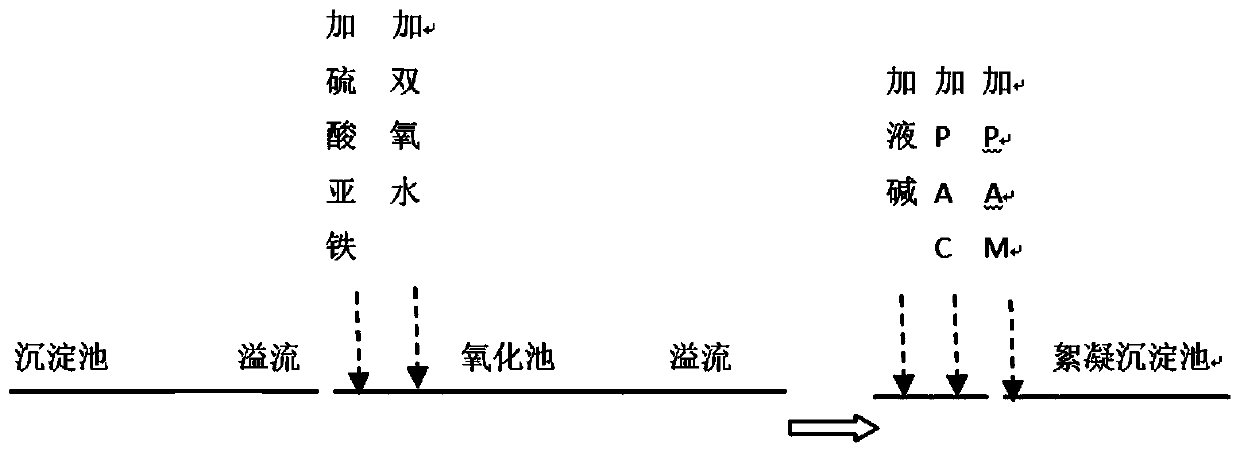

[0012] Such as figure 1 Shown, a kind of triethylamine saline wastewater advanced treatment method provided by the invention comprises the following steps:

[0013] 1) After the triethylamine wastewater is pre-precipitated in the sedimentation tank, part of the calcium sulfate precipitated from supersaturation is removed first;

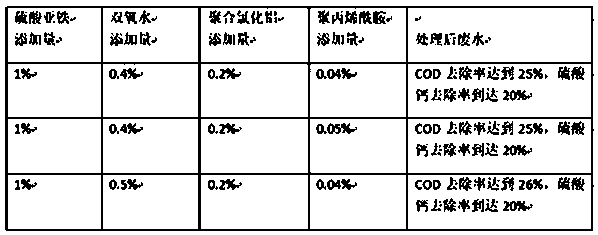

[0014] 2) The pre-precipitated triethylamine wastewater overflows to the oxidation tank, and the oxidation tank is added with ferrous sulfate with a weight ratio of 1% per ton of wastewater and hydrogen peroxide with a weight ratio of 0.4-0.5% per ton of wastewater, and reacts by stirring and mixing. Oxidize part of the organic matter in the triethylamine wastewater, and then undergo coagulation and precipitation;

[0015] 3) The triethylamine wastewater after coagulation and sedimentation overflows to the flocculation sedimentation tank, and the pH is adjusted to 6-7 by adding liquid caustic soda, then adding polyaluminum chloride with a weight rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com