Cullet crushing dust recovery device

A technology for dust recovery and broken glass, applied in glass recovery, recycling technology, grain processing, etc., can solve the problems affecting the health of operators in the workshop environment, the appearance of long glass pieces, and the process of jamming, so as to meet environmental protection requirements. requirements, improve the operating environment of workers, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

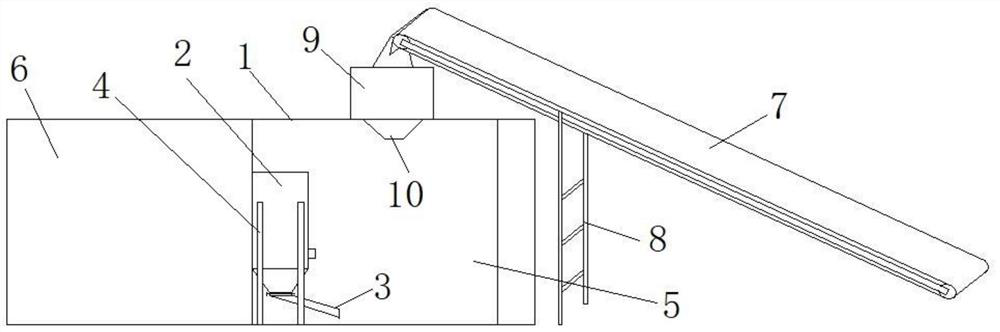

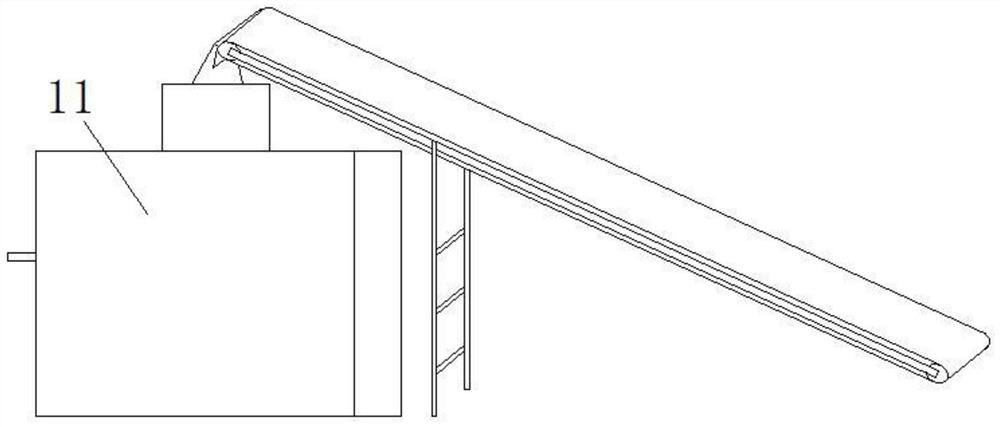

[0031] Such as Figure 1 to Figure 2 As shown, in this embodiment, the dust removal mechanism is a pulse bag filter 2 arranged on the inner side of the powder silo 1 . The pulse bag filter is composed of ash hopper, upper box, middle box, lower box and other parts. The upper, middle and lower boxes are divided into chambers. The exhaust channel of the bag filter extends out of the powder silo. When working, the dusty gas enters the ash hopper through the air inlet, the coarse dust falls directly into the bottom of the ash hopper, and the fine dust enters the middle and lower boxes upwards with the airflow turning, and the dust accumulates on the outer surface of the filter bag. The gas enters the upper box to the clean gas collection pipe-exhaust duct, and is exhausted to the atmosphere through the exhaust fan. The dust cleaning process is to cut off the air outlet duct of the room first, so that the bag in the room is in a state of no air flow (stop the air and clean the du...

Embodiment 2

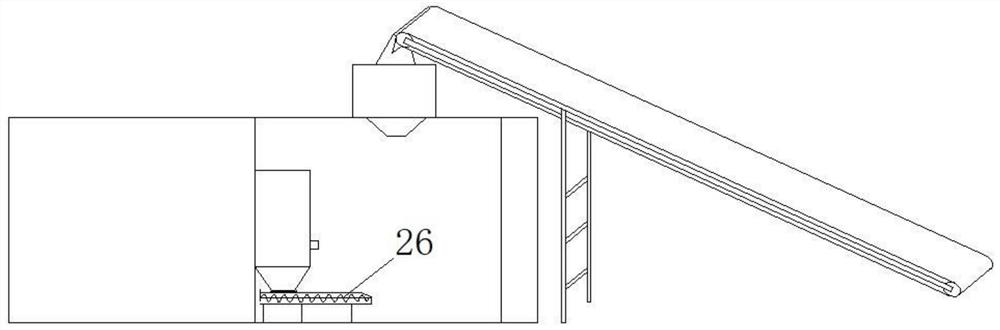

[0039] like Figure 3 to Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the bottom discharge port of the pulse bag filter 2 is connected to the screw discharge mechanism, and the discharge port of the spiral discharge mechanism points to the glass stockpile. The screw discharge mechanism adopts a screw conveyor, the feed port of the screw conveyor is connected with the bottom discharge port of the pulse bag filter, and the discharge port of the screw conveyor points to the glass stockpile. The screw conveyor is fixed on the carrier frame, and the carrier frame is fixed on the bottom surface of the powder silo. With this structure, the pulse bag filter can be directly installed on the screw conveyor, reducing the number of connecting parts between the pulse bag filter and the powder silo. , Reduce installation costs.

[0040] In this embodiment, the crushing mechanism includes a housing 12, a cylinder 13 disposed in the housing 12, and a cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com