A production process of digitally controlled glazed ceramics

A technology of digital control and production technology, which is applied in the field of ceramic production, can solve the problems of not being able to apply various effects of glaze, not being able to apply glaze locally, and uneven glaze application, and achieve the effect of less glaze application, less production equipment, and a strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

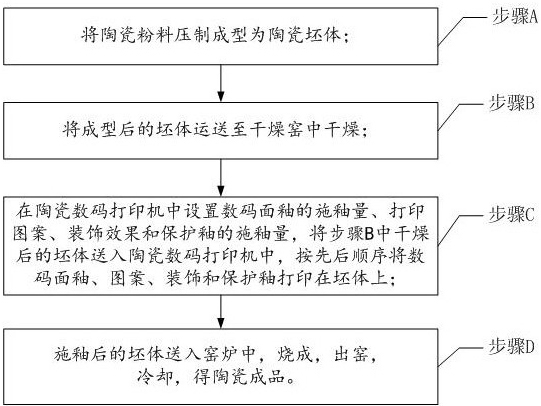

[0034] The production process of the ceramics with digital control glazing comprises the following steps:

[0035] A. The ceramic powder is conveyed by the conveyor belt into the press hopper, and the press is made into a ceramic green body under a pressure of 25MPa;

[0036] B. Transport the shaped body to a multi-layer horizontal drying kiln, and dry it in an air atmosphere of 160°C for 50 minutes;

[0037] C. Add the digital surface glaze with a viscosity of 18mPa·s at 40°C, the glaze required for printing patterns, protective glaze, etc. to the ceramic digital printer, and set the glaze amount of the digital surface glaze in the ceramic digital printer to 120g / m 2 , the pattern to be printed, and the glaze amount of the protective glaze is 40 g / m 2 , sending the dried green body into the ceramic digital printer to print the digital surface glaze, pattern and protective glaze directly on the green body in sequence;

[0038] D. The green body after glazing is sent into the...

Embodiment 2

[0041] The production process of the ceramics with digital control glazing comprises the following steps:

[0042] A. The ceramic powder is conveyed by the conveyor belt into the press hopper, and the press is made into a ceramic green body under a pressure of 35MPa;

[0043] B. Transport the shaped body to a multi-layer horizontal drying kiln, and dry it in an air atmosphere at 150°C for 48 minutes;

[0044] C. Add the digital surface glaze with a viscosity of 20mPa·s at 40°C, the glazes required for printing patterns, decorations, protective glazes, etc. to the ceramic digital printer, and set the glaze amount of the digital surface glaze in the ceramic digital printer to 200g / m 2 , the pattern to be printed, the decorative effect, the amount of glaze applied to the protective glaze is 100 g / m 2 , sending the dried green body into a ceramic digital printer to directly print the digital surface glaze, pattern, decoration and protective glaze on the green body in sequence; ...

Embodiment 3

[0048] The production process of the ceramics with digital control glazing comprises the following steps:

[0049] A. The ceramic powder is conveyed by the conveyor belt into the press hopper, and the press is made into a ceramic green body under a pressure of 50MPa;

[0050] B. Transport the formed body to a multi-layer horizontal drying kiln, and dry it in an air atmosphere at 170°C for 45 minutes;

[0051] C. Add the digital surface glaze with a viscosity of 13mPa·s at 40°C, the glazes required for printing patterns, decorative and protective glazes to the ceramic digital printer, and set the glaze amount of the digital surface glaze in the ceramic digital printer to 100g / m 2 , the amount of glaze to be printed, decorative effect, and protective glaze is 60g / m 2 , sending the dried green body into a ceramic digital printer to directly print the digital surface glaze, pattern, decoration and protective glaze on the green body in sequence;

[0052] D. The green body after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com