Filtrate reducer for drilling fluid as well as preparation method and application thereof

A technology of fluid loss reducer and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as abnormal drilling work, excessive addition, and increased economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

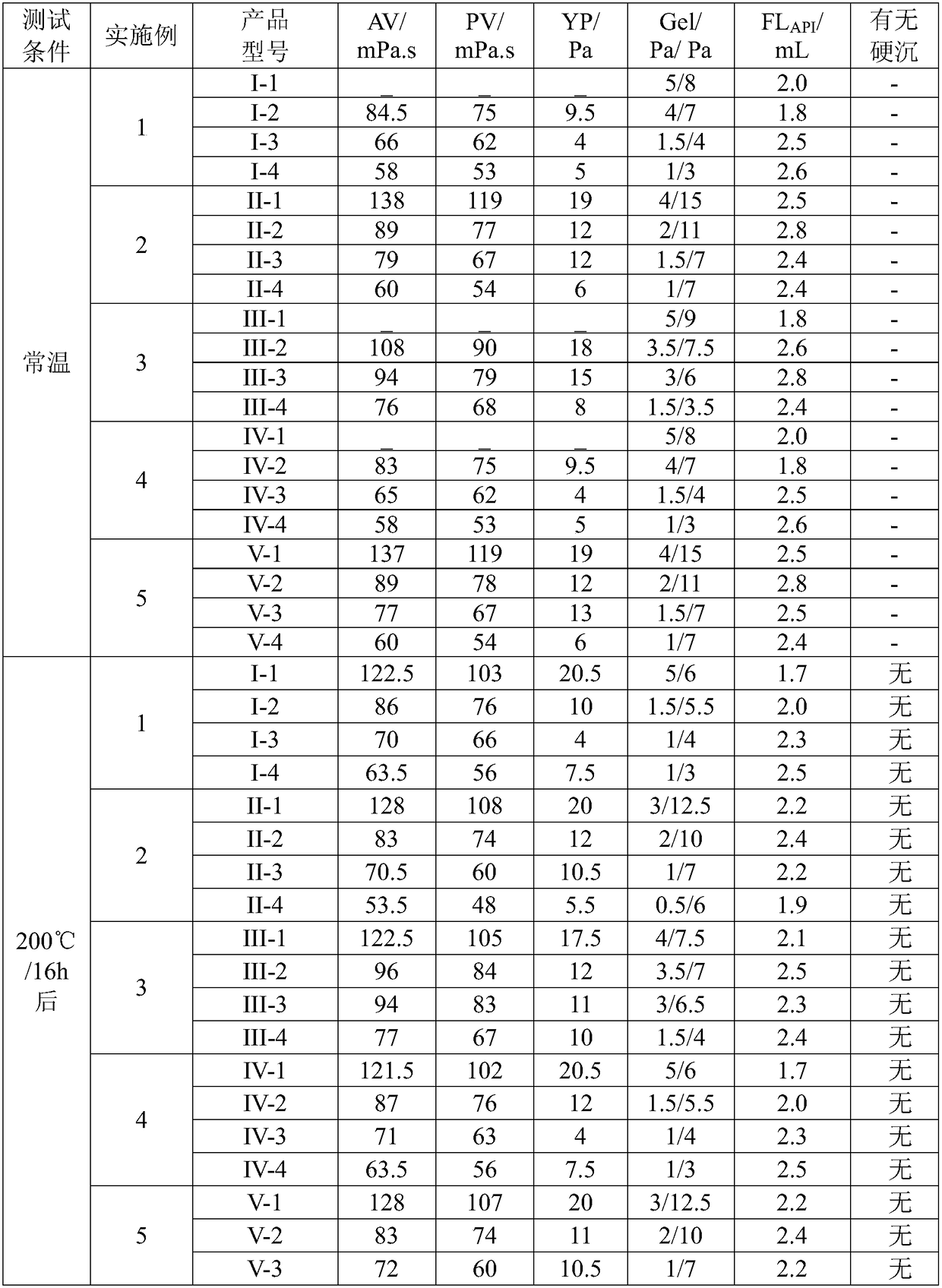

Examples

Embodiment 1

[0074] Prepare according to the composition ratio of Table 1, specifically:

[0075] (1) Add water, starch, tetrahydrofuran and maleic anhydride to the reaction kettle and stir, adjust the pH to 7, raise the temperature to 50°C and keep it for 4h;

[0076] (2) Continue to add acrylamidopropyltrimethoxysilane, 2-acrylamide-2-methylpropanesulfonic acid, dimethyl sulfoxide and N-benzyl-3-pyrrolidone to the reactor, and then pass into nitrogen After 1.5h, add ammonium persulfate, sodium bisulfite and alkyl betaine under the protection of nitrogen atmosphere, raise the temperature to 60°C and stir for 5h at a speed of 1200r / min;

[0077] (3) Cool to room temperature, shear and granulate, dry and pulverize to obtain fluid loss reducer for drilling fluid.

Embodiment 2

[0079] Prepare according to the composition ratio of Table 1, specifically:

[0080] (1) Add water, starch, tetrahydrofuran and maleic anhydride to the reaction kettle and stir, adjust the pH to 10, raise the temperature to 60°C and keep it for 3h;

[0081] (2) Continue to add acrylamidopropyltrimethoxysilane, 2-acrylamide-2-methylpropanesulfonic acid, dimethyl sulfoxide and N-benzyl-3-pyrrolidone to the reactor, and then pass into nitrogen After 1h, ammonium persulfate, sodium bisulfite and alkyl betaine were added under the protection of nitrogen atmosphere, the temperature was raised to 70°C and stirred at a speed of 1000r / min for 7h;

[0082] (3) Cool to room temperature, shear and granulate, dry and pulverize to obtain fluid loss reducer for drilling fluid.

Embodiment 3

[0084] Prepare according to the composition ratio of Table 1, specifically:

[0085] (1) Add water, starch, tetrahydrofuran and maleic anhydride to the reaction kettle and stir, adjust the pH to 8, raise the temperature to 70°C and keep it for 2h;

[0086] (2) Continue to add acrylamidopropyltrimethoxysilane, 2-acrylamide-2-methylpropanesulfonic acid, dimethyl sulfoxide and N-benzyl-3-pyrrolidone to the reactor, and then pass into nitrogen After 0.5h, add ammonium persulfate, sodium bisulfite and alkyl betaine under the protection of nitrogen atmosphere, raise the temperature to 80°C and stir at a speed of 800r / min for 6h;

[0087] (3) Cool to room temperature, shear and granulate, dry and pulverize to obtain fluid loss reducer for drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com