Water-soluble organic salt weighting agent for drilling fluid for oilfields as well as preparation method and application thereof

An organic salt and water-soluble technology, which is applied in the field of water-soluble organic salt weighting agents, can solve the problems of not mentioning the preparation method, not giving the specific composition of the weighting agent, and not disclosing the specific components of the weighting agent, so as to overcome the difficulty of viscosity Control, low solid content, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare the water-soluble organic salt weighting agent of the present embodiment according to the following raw material formula:

[0033] Organic acid: 60 kg ClCOOH, 90 kg CH 2 ClCOOH, 60 kg CH 3 CHClCOOH, 110 kg CH 3 CH 2 CHClCOOH, 110 kg CH 3 CH 2 CH 2 CHClCOOH, 35 kg CH 3 CH 2 CH 2 CH 2 CHClCOOH, the purity of the above organic acids are 93%, 99%, 95%, 94%, 94%, 93% respectively.

[0034] Compound alkali: 23 kg NaOH, 58 kg KOH, 35 kg ammonia water, 10 kg N(CH 3 ) 3 Aqueous solution, 5 kilograms of epichlorohydrin, the purity of above each raw material is respectively 96%, 92%, 25%, 30%, 99%.

[0035] Concrete preparation steps are as follows:

[0036] a. Add various organic acids into the kneading reactor, knead and stir for 10-30 minutes until the stirring is uniform;

[0037] b. Add compound base, make it and each component in step a stir evenly and be pasty, continue to knead and stir for 1 hour, in the process of stirring, reaction exothermic, mois...

Embodiment 2

[0041] Prepare the water-soluble organic salt weighting agent of the present embodiment according to the following raw material formula:

[0042] Organic acid: 65 kg ClCOOH, 85 kg CH 2 ClCOOH, 65 kg CH 3 CHClCOOH, 110 kg CH 3 CH 2 CHClCOOH, 105 kg CH 3 CH 2 CH 2 CHClCOOH, 30 kg CH 3 CH 2 CH 2 CH 2 CHClCOOH, the purity of the above organic acids are 93%, 99%, 95%, 94%, 94%, 93% respectively.

[0043] Compound alkali: 25 kg NaOH, 60 kg KOH, 35 kg ammonia water, 10 kg N(CH 3 ) 3 , 5 kilograms of epichlorohydrin, the purity of each alkali above is respectively 96%, 92%, 25%, 30%, 99%.

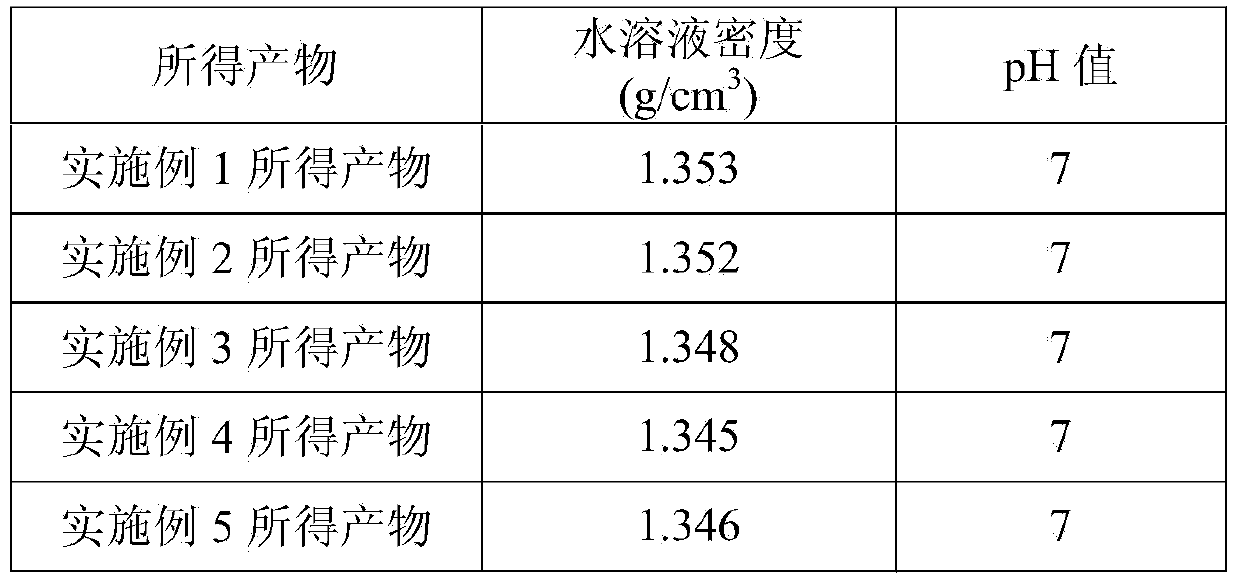

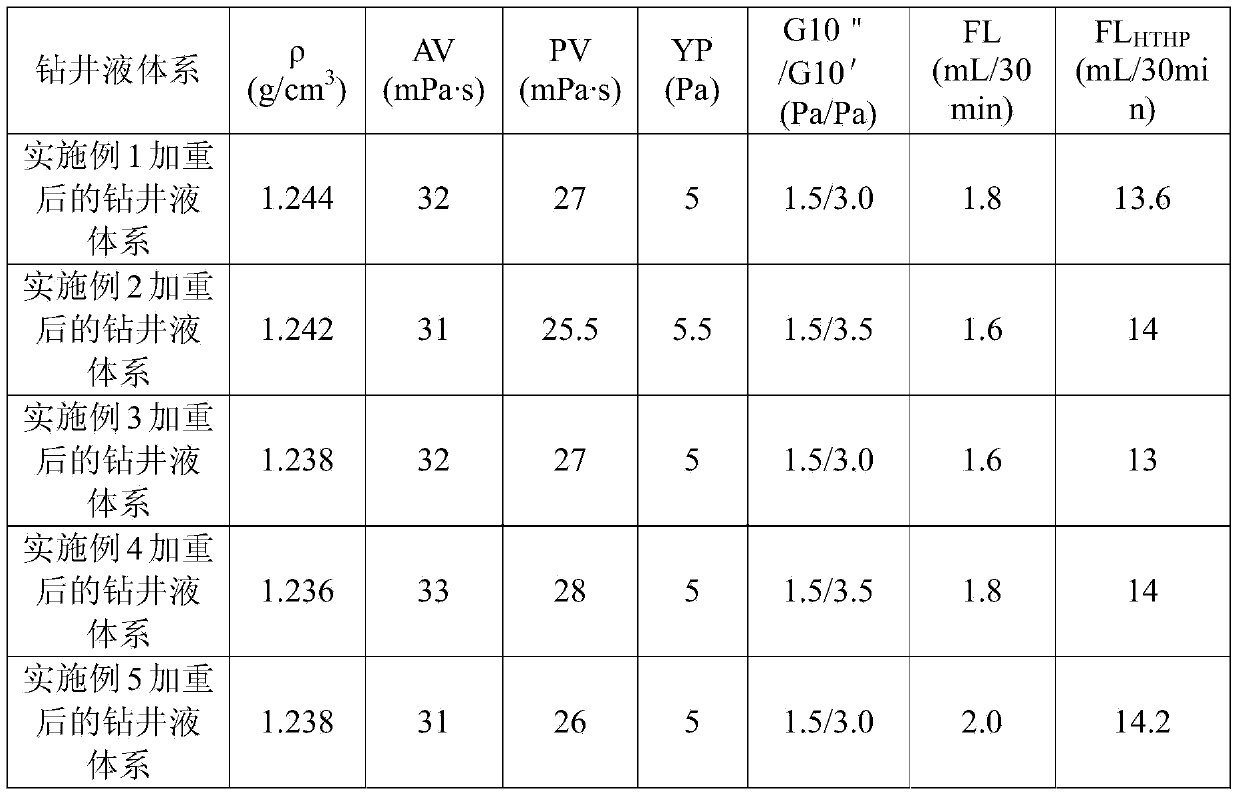

[0044] The preparation process is basically the same as in Example 1. The product was tested for performance, and the results are shown in Table 1.

Embodiment 3

[0046] Prepare the water-soluble organic salt weighting agent of the present embodiment according to the following raw material formula:

[0047] Organic acid: 90 kg HCOOH, 105 kg CH 2 ClCOOH, 50kg CH 3 CHClCOOH, 80 kg CH 3 CH 2 CHClCOOH, 100 kg CH 3 CH 2 CH 2 CHClCOOH, 50 kg CH 3 CH 2 CH 2 CH 2 CHClCOOH, the purity of the above organic acids are 93%, 99%, 95%, 94%, 94%, 93% respectively.

[0048] Compound alkali: 26 kg NaOH, 60 kg KOH, 36 kg ammonia water, 10 kg N(CH 3 ) 3 , 5 kilograms of epichlorohydrin, the purity of each alkali above is respectively 96%, 92%, 25%, 30%, 99%.

[0049] The preparation process is basically the same as in Example 1. The product was tested for performance, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com