Fluid loss reducer for soilless high-density saturated brine drilling fluid and preparation method thereof

A saltwater drilling fluid and fluid loss reducing agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of polluted oil and gas reservoirs, submicron viscosity out of control, and complex viscosity increase in downholes, etc. Toxicity, avoid complex effects downhole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

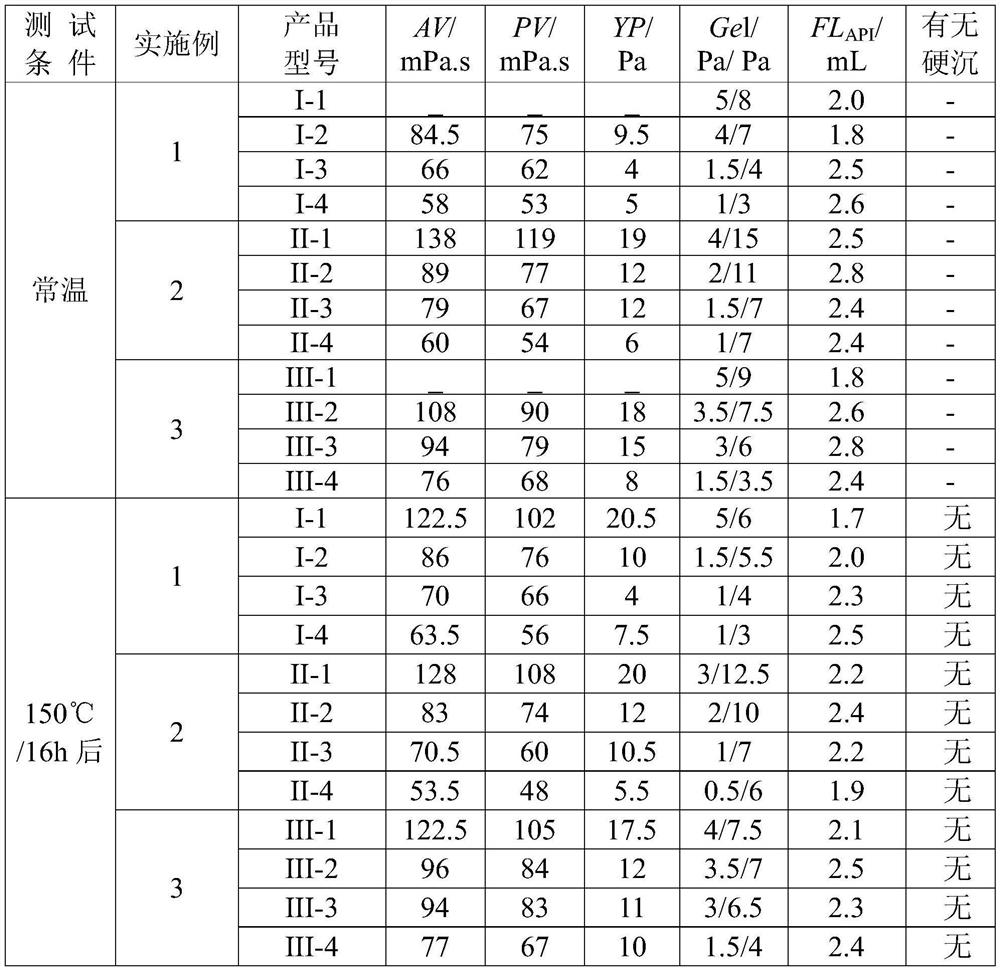

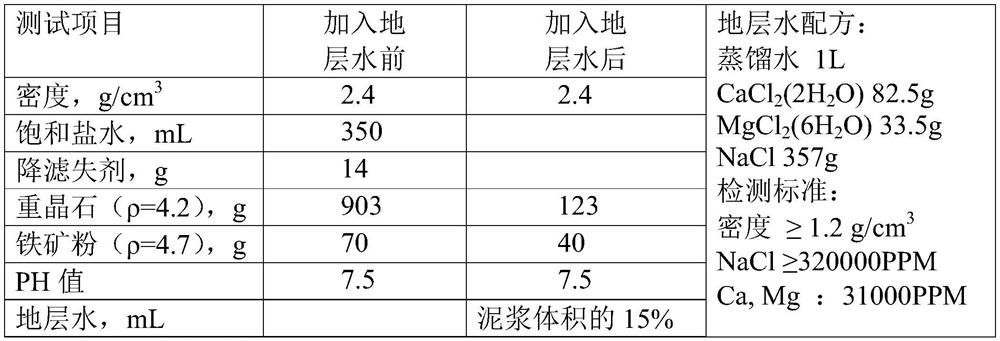

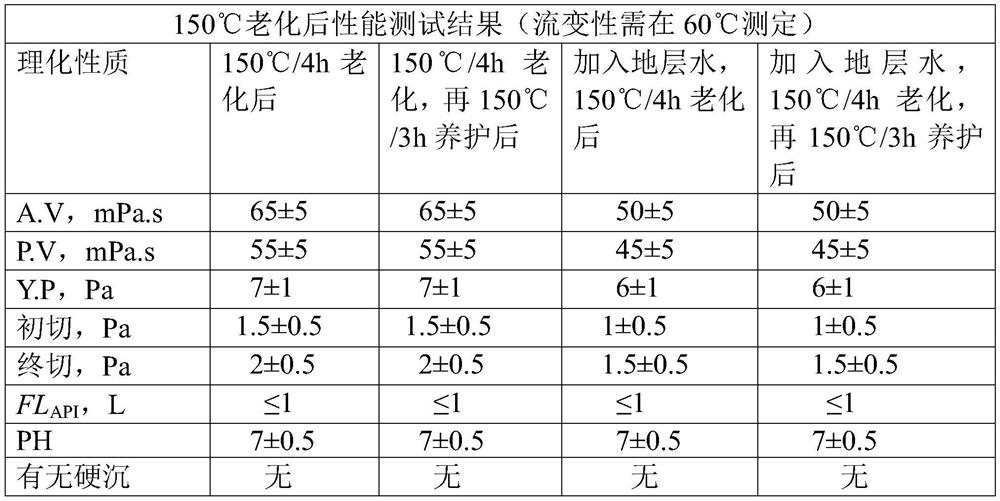

Examples

Embodiment 1

[0037] Fluid loss control agent for high-density saturated brine drilling fluid without soil phase I:

[0038] Weigh 100 parts by weight of water and 25 parts by weight of cornstarch, add them to the reactor, stir to dissolve them, add 3.75 parts by weight of sodium hydroxide, and raise the temperature to 60 ° C, keep it warm for 1 hour; add 5 parts by weight to the reactor 2-methyl-2-acrylamidopropanesulfonic acid and 5 parts by weight of N-vinylpyrrolidone, after nitrogen gas for 30 minutes, add 0.5 parts by weight of ammonium persulfate-sodium bisulfite (molar ratio 1:1.2), keep warm 3h, obtain the mixed solution containing polymer A;

[0039] Weigh 50 parts by weight of water, 50 parts by weight of tetrahydrofuran, 10 parts by weight of N,N-diethylacrylamide, 5 parts by weight of 3-acetyl-N-vinylpyrrolidone, stir and dissolve and add 10 parts by weight of 3-acrylamide Propyl tris(trimethylsiloxy)silane, after 30 minutes of blowing nitrogen into the reaction kettle, continue...

Embodiment 2

[0042] Fluid loss control agent for high-density saturated brine drilling fluid without soil phase II:

[0043] Weigh 100 parts by weight of water and 20 parts by weight of wheat starch, add them into the reaction kettle, stir to dissolve them, add 3 parts by weight of sodium hydroxide, and raise the temperature to 55 ° C, keep it warm for 1 hour; add 10 parts by weight to the reaction kettle Part of 2-methyl-2 acrylamidopropanesulfonic acid and 5 parts by weight of itaconic acid, after passing nitrogen in the reactor for 30 minutes, continue to add 0.4 parts by weight of potassium persulfate-sodium bisulfite (molar ratio 1:1.2 ), insulation 4h, obtain the mixed solution that contains polymer A;

[0044] Weigh 50 parts by weight of water, 50 parts by weight of tetrahydrofuran, 15 parts by weight of acrylamide, 5 parts of N-vinylpyrrolidone, stir and dissolve and add 5 parts of N-(3-triethoxysiloxane) propyl propylene Amide, after nitrogen gas was blown into the reaction kettl...

Embodiment 3

[0047] Fluid loss control agent product III for soil-free high-density saturated brine drilling fluid:

[0048] Weigh 100 parts by weight of water and 30 parts by weight of cornstarch, add them to the reactor, stir to dissolve them, add 4.5 parts by weight of sodium hydroxide, and raise the temperature to 55 ° C, keep it warm for 1 hour; add 5 parts by weight to the reactor Part of N-vinylpyrrolidone, after passing nitrogen in the reactor for 30 minutes, continue to add 0.3 weight ammonium persulfate-sodium sulfite (molar ratio 1:1.2), keep warm for 4h, and obtain a mixed solution containing polymer A;

[0049] Weigh 50 parts by weight of water, 50 parts by weight of tetrahydrofuran, 15 parts by weight of N,N-dimethylacrylamide, 10 parts by weight of 3-acetyl-N-vinylpyrrolidone, stir and dissolve and add 5 parts by weight of methacryloxy Propyl tris(trimethylsiloxane) silane, after blowing nitrogen into the reaction kettle for 30 minutes, continue to add 0.5 parts by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com