Polyurethane sieve mesh with advantages of noise reducing, high-temperature resistance and corrosion resistance

A technology of high temperature resistance and corrosion resistance, which is applied in the field of noise-reducing, high-temperature and corrosion-resistant polyurethane screens. It can solve problems such as easy yellowing, poor high temperature resistance, and poor durability, and achieve improved antistatic performance, long service life, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

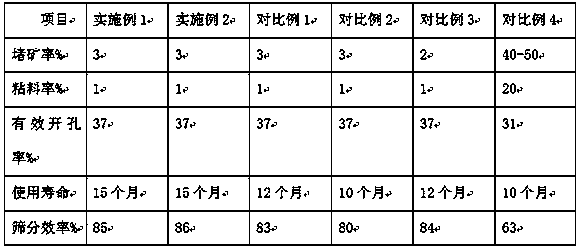

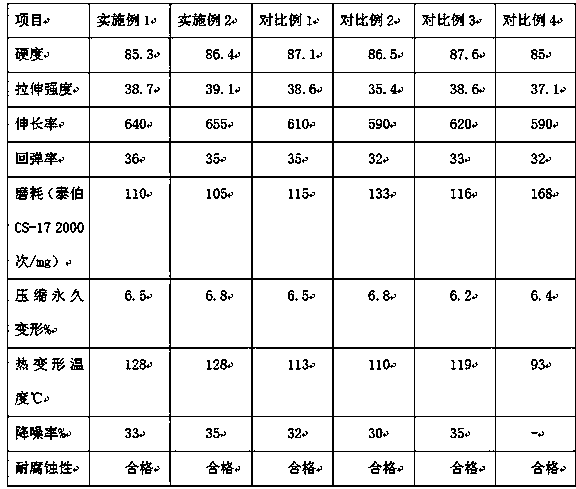

Examples

Embodiment 1

[0024] A noise-reducing, high-temperature, corrosion-resistant polyurethane screen made of the following raw materials in parts by weight:

[0025] 98 parts of thermoplastic polyurethane, 25 parts of vinyl ester resin, 1.8 parts of melamine, 1.2 parts of terpene resin, 10 parts of carboxyl-terminated liquid nitrile rubber, 10 parts of chlorinated polyethylene, 0.8 parts of titanate coupling agent, 20 parts of filler .

[0026] A noise-reducing high-temperature-resistant and corrosion-resistant polyurethane screen, comprising the following steps: (1) Weighing each raw material, magnesium silicate, sintered porcelain powder, cement powder, barite powder, kaolinite powder, wollastonite powder, melamine, Fly ash and serpentine powder are dried, ground, stirred and mixed, and added with titanate coupling agent for coupling surface treatment to obtain mixture A for later use; (2) thermoplastic polyurethane, carboxyl-terminated liquid nitrile rubber, chlorinated polystyrene After et...

Embodiment 2

[0032] A noise-reducing, high-temperature, corrosion-resistant polyurethane screen made of the following raw materials in parts by weight:

[0033] 98 parts of thermoplastic polyurethane, 32 parts of vinyl ester resin, 1.3 parts of melamine, 1 part of terpene resin, 13 parts of carboxyl-terminated liquid nitrile rubber, 12 parts of chlorinated polyethylene, 0.7 parts of titanate coupling agent, 20 parts of filler .

[0034] A noise-reducing, high-temperature, corrosion-resistant polyurethane screen, comprising the following steps: (1) Weighing each raw material, drying, grinding, stirring and mixing the filler, and adding a titanate coupling agent for coupling surface treatment to obtain a mixture A Standby; (2) After stirring and mixing thermoplastic polyurethane, melamine, carboxyl-terminated liquid nitrile rubber, chlorinated polyethylene, and vinyl ester resin, add mixture A, and after stirring, put it into the extruder and enter the barrel; (3 ) Extrude the mixture of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com