Environment-friendly type dry refuse incineration and waste gas treatment system

A technology for waste incineration and waste gas treatment, which is applied to the treatment of combustion products, incinerators, and combustion methods. It can solve the problems of failing to meet the requirements of environmental protection treatment of waste, the gas failing to meet the national emission standards, and the system not having environmental protection value. Achieve the effects of improving service life, saving labor, and meeting environmental protection treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

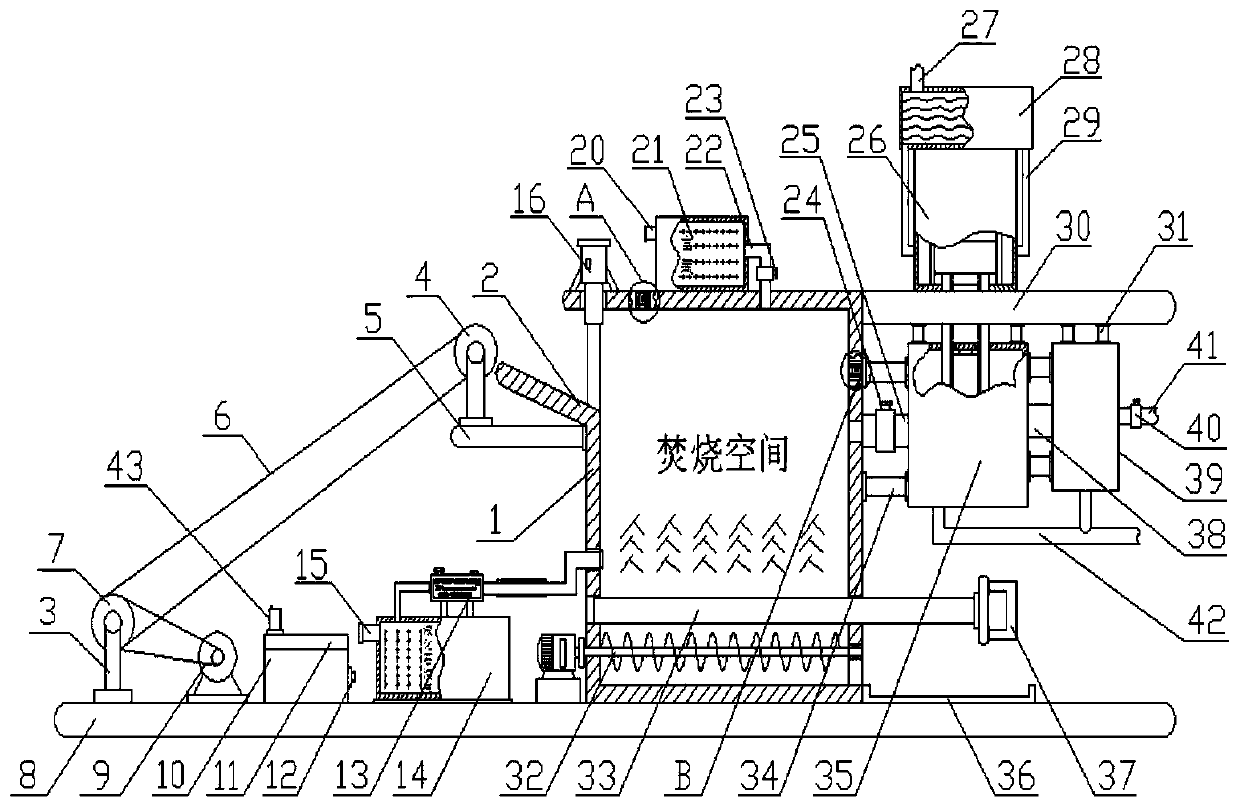

[0046] Example: as attached figure 1 to attach Figure 16 shown

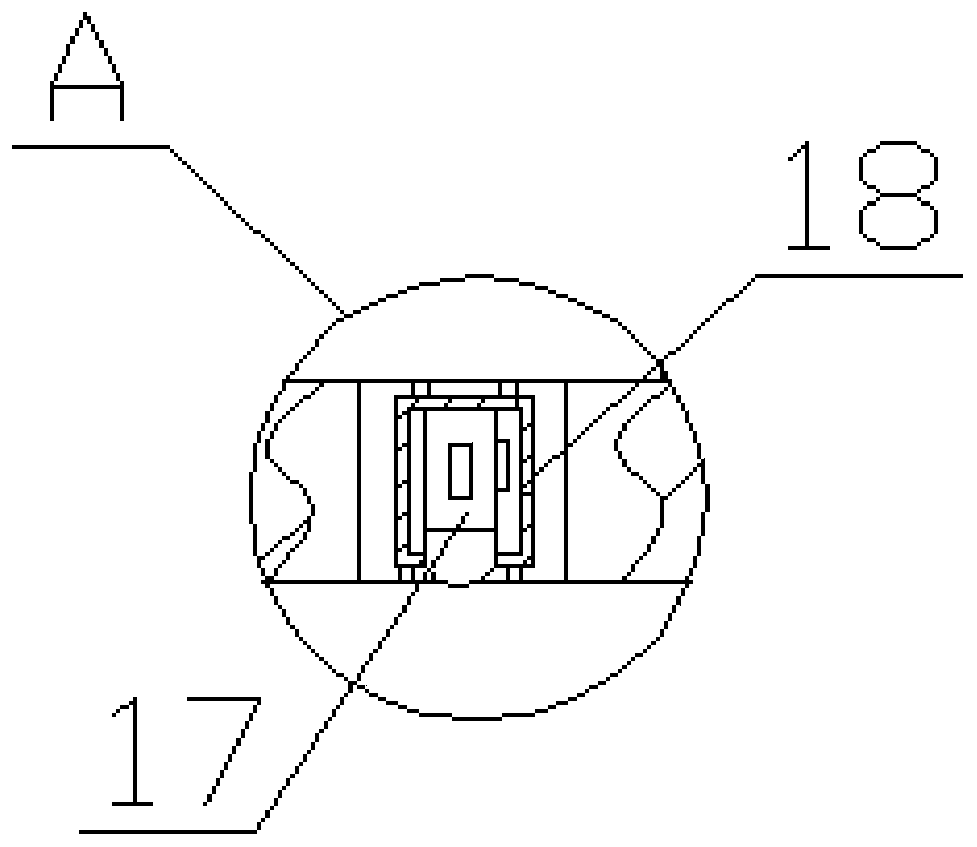

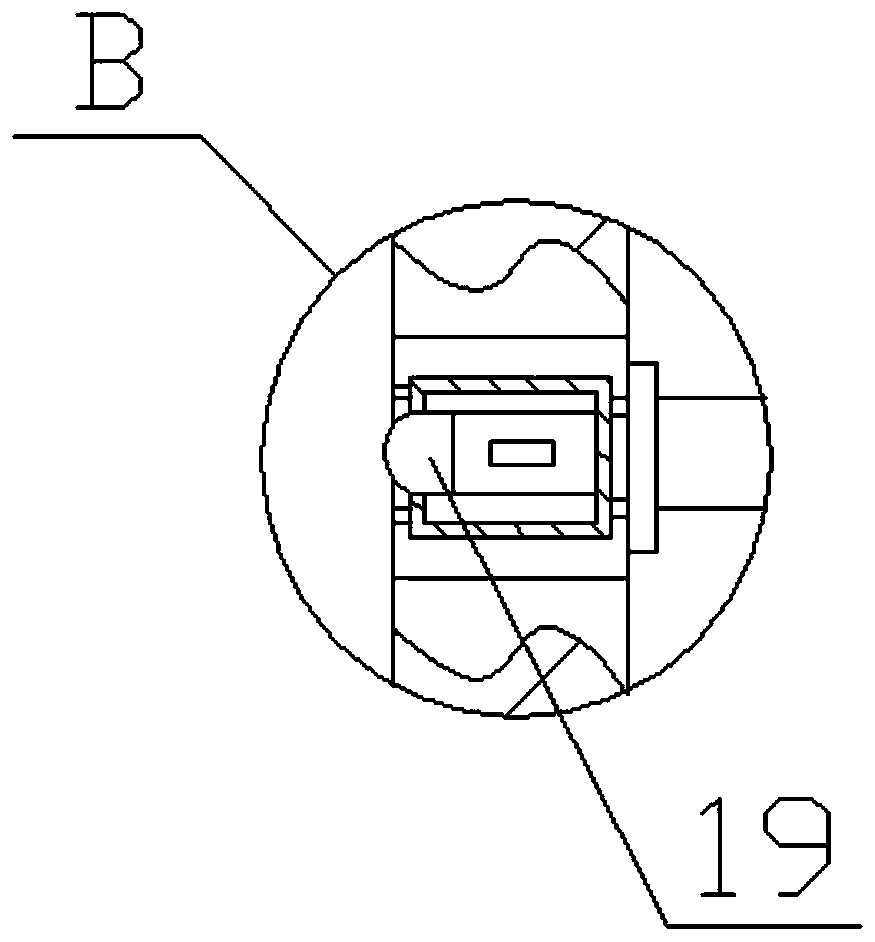

[0047] The present invention provides an environment-friendly dry garbage incineration system and its exhaust gas treatment system, which includes an incinerator wall 1, a material guide slant plate 2, a support frame 3, a No. 1 transmission wheel 4, a support plate 5, a conveyor belt 6, and a No. 2 transmission wheel 7 , bottom plate 8, material guide motor 9, controller 10, remote control switch group 11, main switch 12, liquefied flamethrower 13, liquefied petroleum tank 14, liquefied petroleum gas filling port 15, electric telescopic rod 16, oxygen sensor 17, heat resistance Cover 18, temperature sensor 19, oxygen-enriched filling port 20, oxygen-enriched tank 21, oxygen-inflating pipe 22, solenoid valve 23 for oxygen guide, exhaust-gas solenoid valve 24, exhaust-gas outlet pipe 25, reciprocating cleaning mechanism 26, water-filling pipe 27, Water tank 28, water guide pipe 29, mounting plate 30, stabilizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com