A water-spray type self-driven spiral traveling tank wall intelligent cleaning device

An intelligent cleaning and self-driving technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high labor intensity, low scouring force, secondary pollution, etc., so as to reduce the risk of endangering health. , Improve cleaning efficiency and increase the effect of cleaning strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

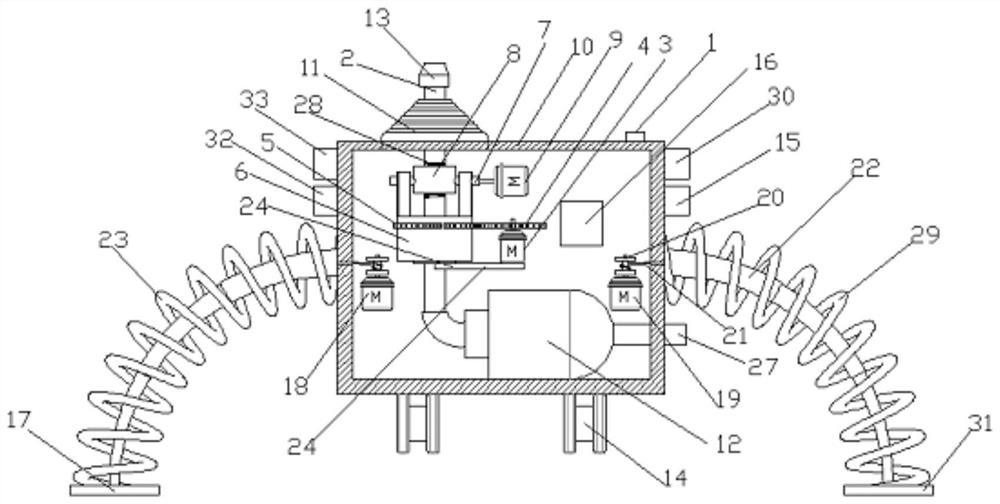

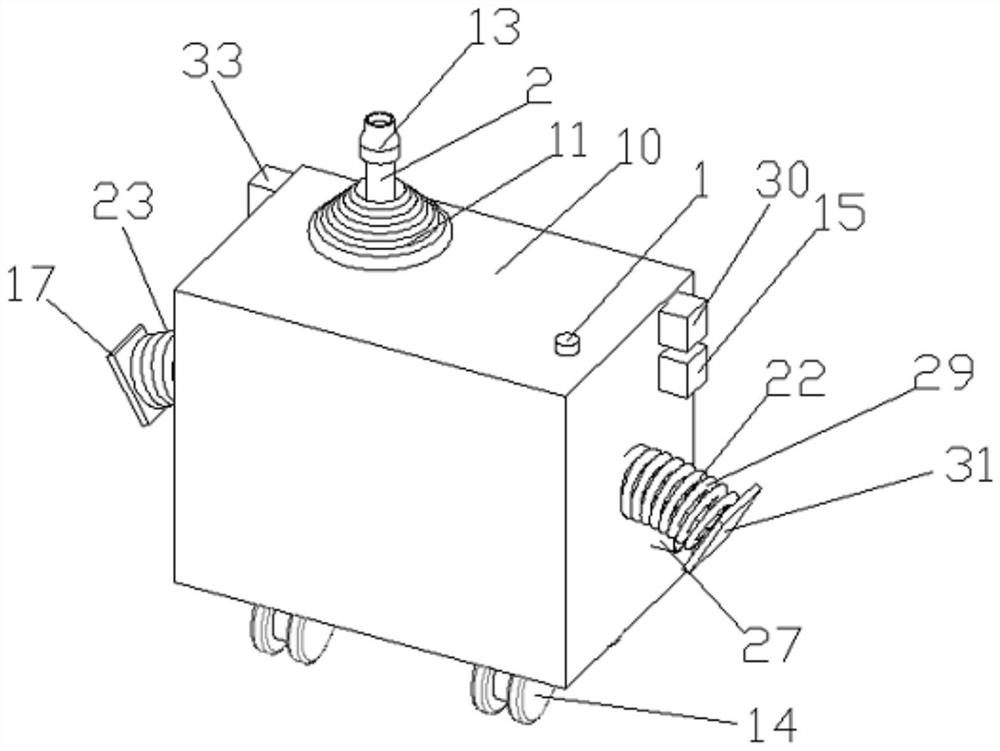

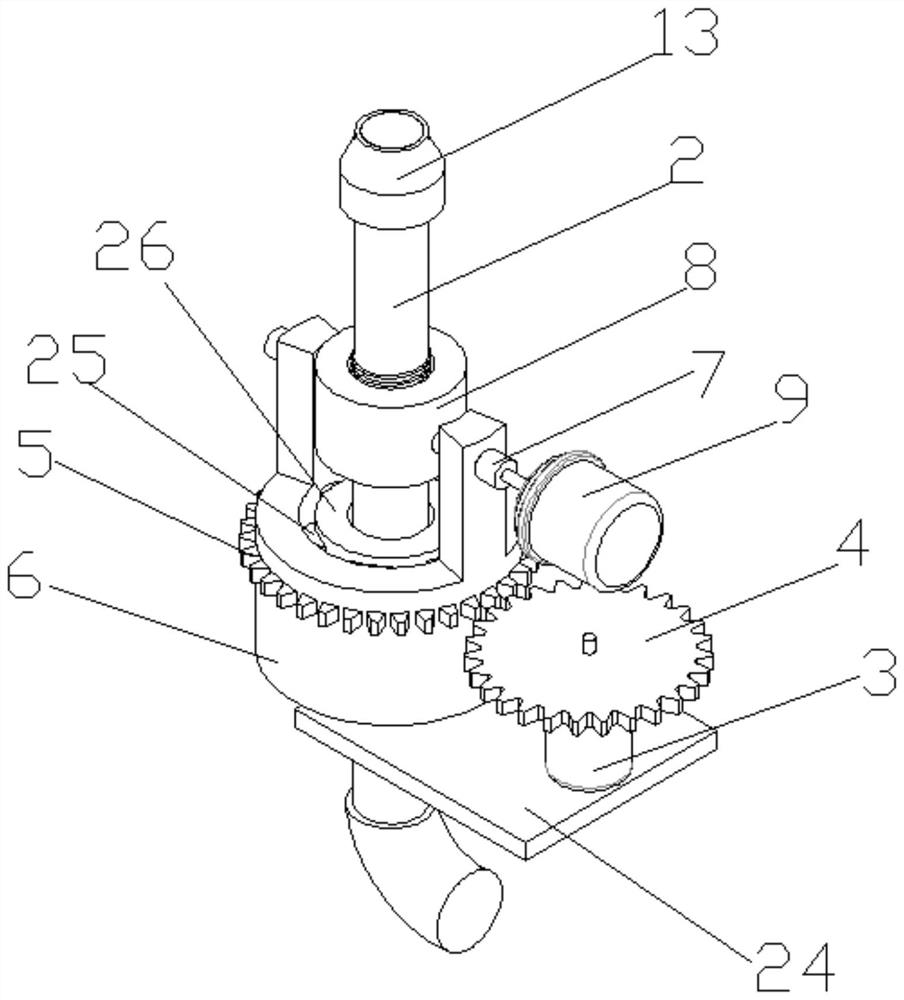

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Put the water spray type self-driven spiral advancing tank wall intelligent cleaning device into the inner wall of the storage tank, start the switch button 1, and the water spray angle control system adjusts the direction of the water outlet pipe 2 to the angle of the spiral advance: the motor A3 rotates, through the driving gear 4 and The driven gear 5 drives the rotating outer column 6 to rotate, and the rotating outer column 6 rotates to drive the rotating shaft 7 and the deflection ring 8 to rotate in the horizontal plane, so that the water outlet pipe 2 rotates in the horizontal direction, and the rotation of the motor B 9 drives the rotating shaft 7 to rotate, and the deflection ring 8 deflects in the vertical plane, then the water outlet pipe 2 deflects in the vertical plane direction. The elastic waterproof membrane 11 installed in the opening of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com