A kind of flake nanomaterial for oil displacement

A nano-material and oil displacement technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficult production fluid treatment, mechanical and chemical degradation, and concentration drop, and achieve excellent water solubility and easy storage , the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

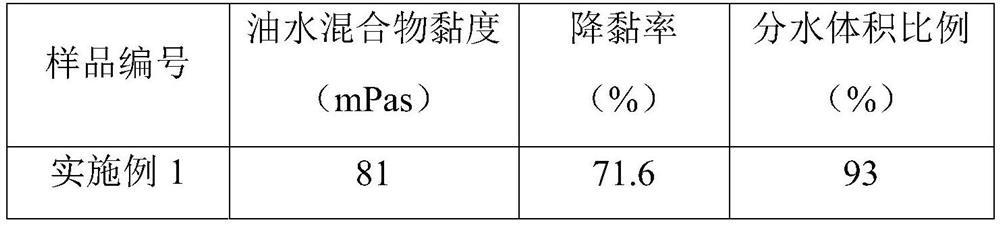

Examples

Embodiment 1

[0066] (1) Preparation of hydrophobic compounds

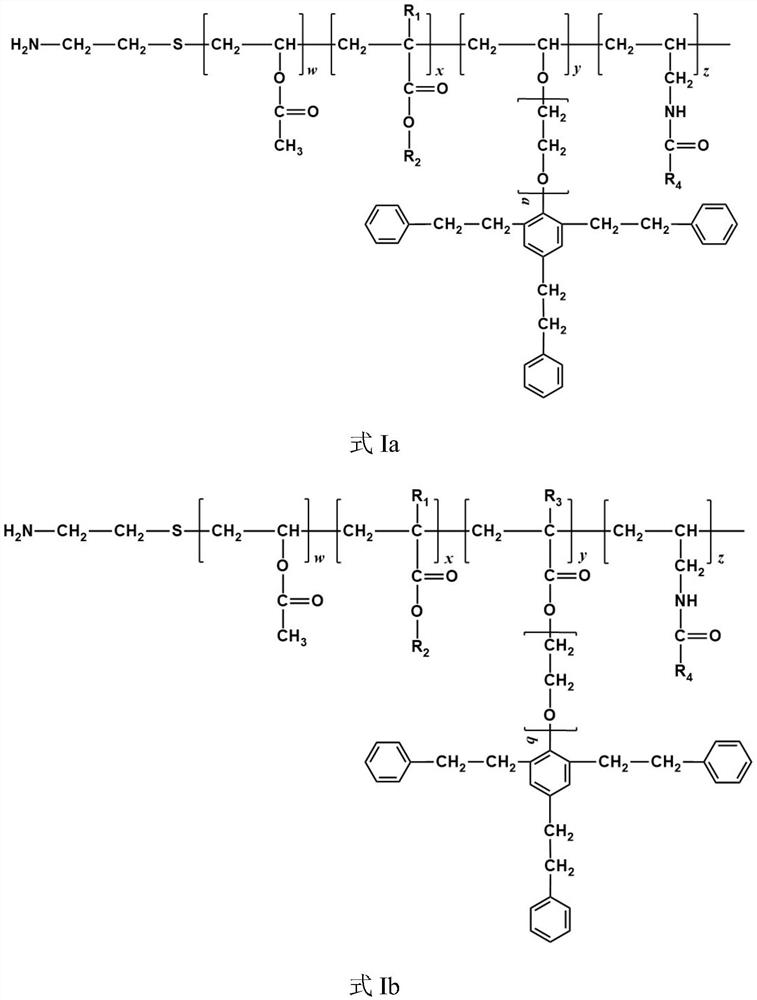

[0067] 3g (0.018mol) azobisisobutyronitrile, 1g (0.013mol) mercaptoethylamine, 4.5g (0.052mol) monomer A, 20g (0.108mol) monomer B (R 1 for H, R 2 is n-octyl), 3.5g (0.006mol) monomer C (C-1, a is 3), 1.5g (0.012mol) monomer D (R 4 N-propyl), 180g of dimethylformamide, were added to a four-neck glass bottle equipped with a stirrer, a nitrogen pipe, a spherical condenser and a thermometer, and stirred until all the raw materials were dissolved, then nitrogen gas was introduced for 30 minutes, and the polymerization temperature Control at 65°C, polymerize for 5 hours, wash the product with ethanol / water mixed solution, and distill off volatile components under reduced pressure at 50°C to obtain a hydrophobic compound;

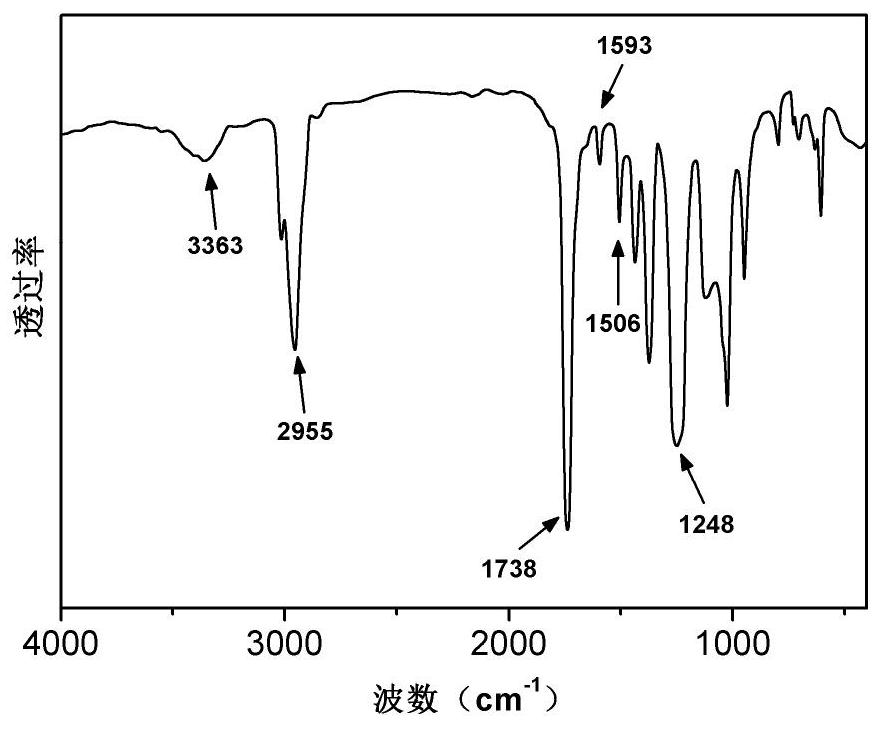

[0068] The structural confirmation data of this compound are as follows figure 1 shown.

[0069] It can be seen from the figure that the product has a correct structure and is the target product.

[0070] (2)...

Embodiment 2

[0075] As described in Example 1, the difference is that the amount of azobisisobutyronitrile added in step (1) is 4 g.

Embodiment 3

[0077] As described in Example 1, the difference is that the addition of monomer A in step (1) is 7 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com