Wool-polyester graphene elastic woolen cloth and production method thereof

A production method and graphene technology, applied in textiles, woven fabrics, fabrics, etc., can solve rare and other problems, achieve the effect of powerful heating and heat storage, increase color fastness, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

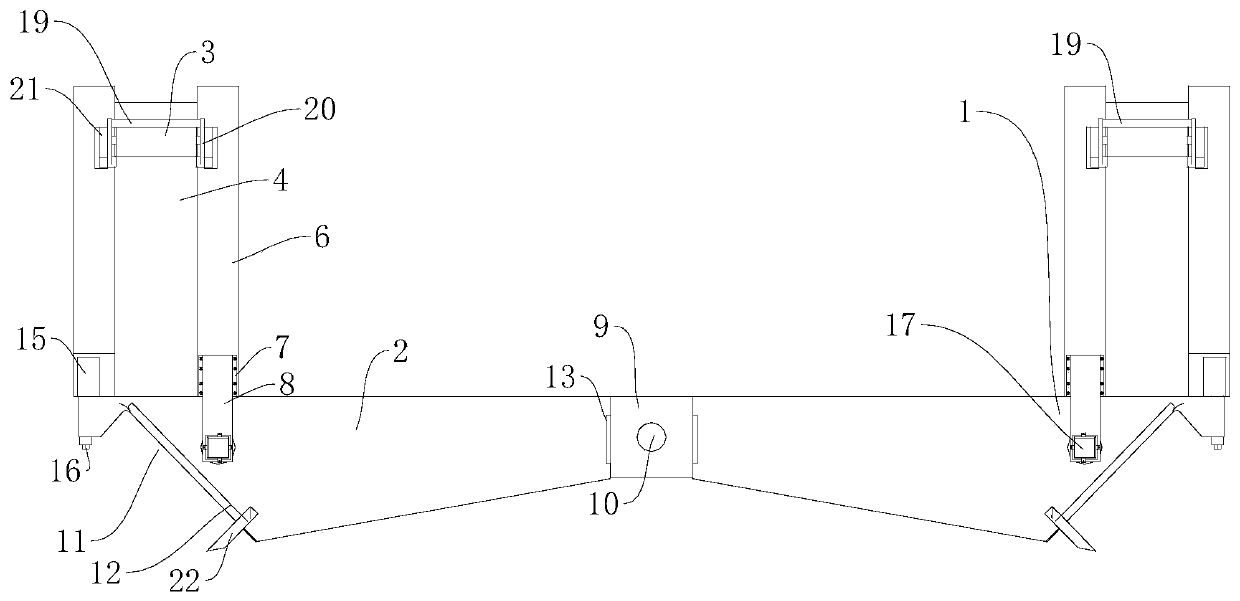

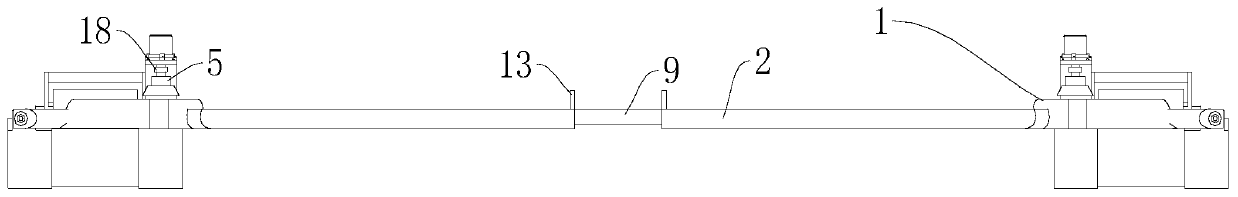

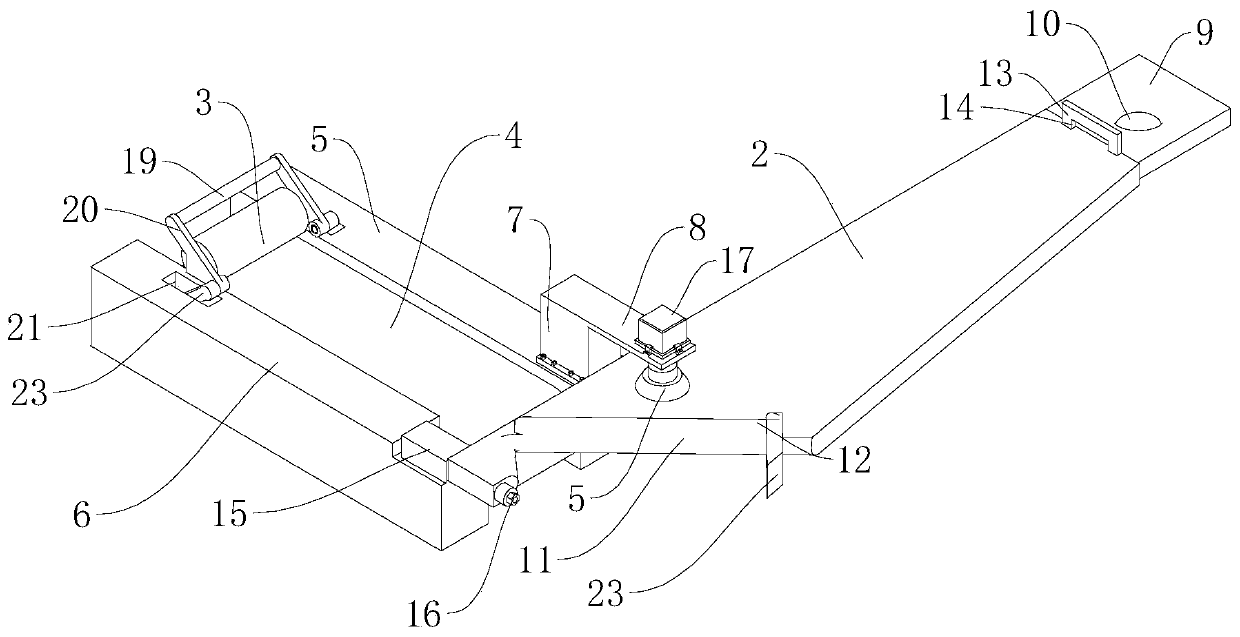

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0031] A wool polyester graphene elastic cloth, the warp yarn of the wool polyester graphene elastic cloth adopts 40wt% 66S wool and 60wt% graphene wool type polyester fiber, and the weft yarn of the wool polyester graphene elastic cloth adopts 40wt% 66S Wool, 40wt% graphene wool type polyester fiber and 20wt% PTT fiber, the yarn count of warp yarn and weft yarn is 72Nm / 2, and described wool polyester graphene stretch cloth is formed by warp yarn and weft yarn blending. Among them, the graphene wool-type polyester fiber adopts the biomass graphene wool-type fiber produced by Shandong Shengquan Group, the specification is 2.5D*88mm, and the graphene content is 1%.

[0032] Further, the warp density of the wool polyester graphene elastic cloth is 278 threads / 10cm, the weft dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com