Novel multi-component spinning spinneret plate

A spinneret and multi-component technology, applied in the field of spinning, can solve the problems of single structure and inability to manufacture fibers, and achieve the effects of prolonging service life, uniform filament output, and promoting melt flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

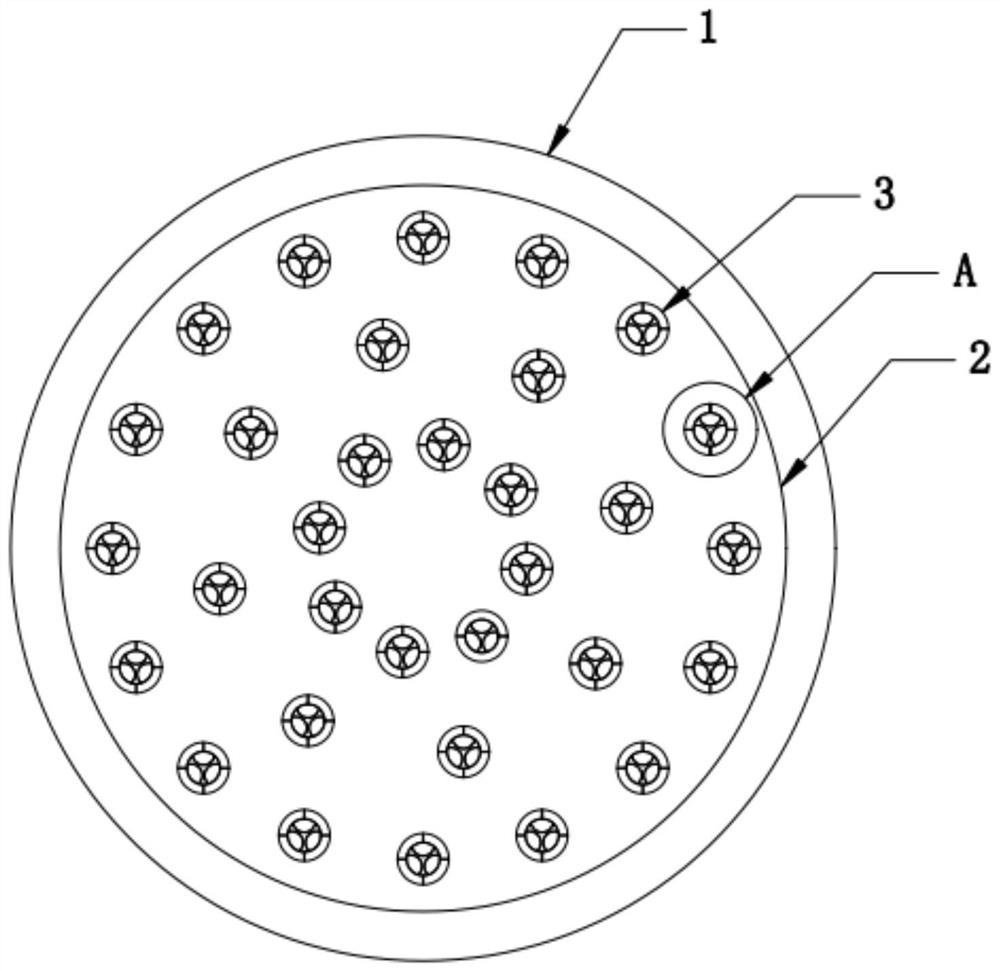

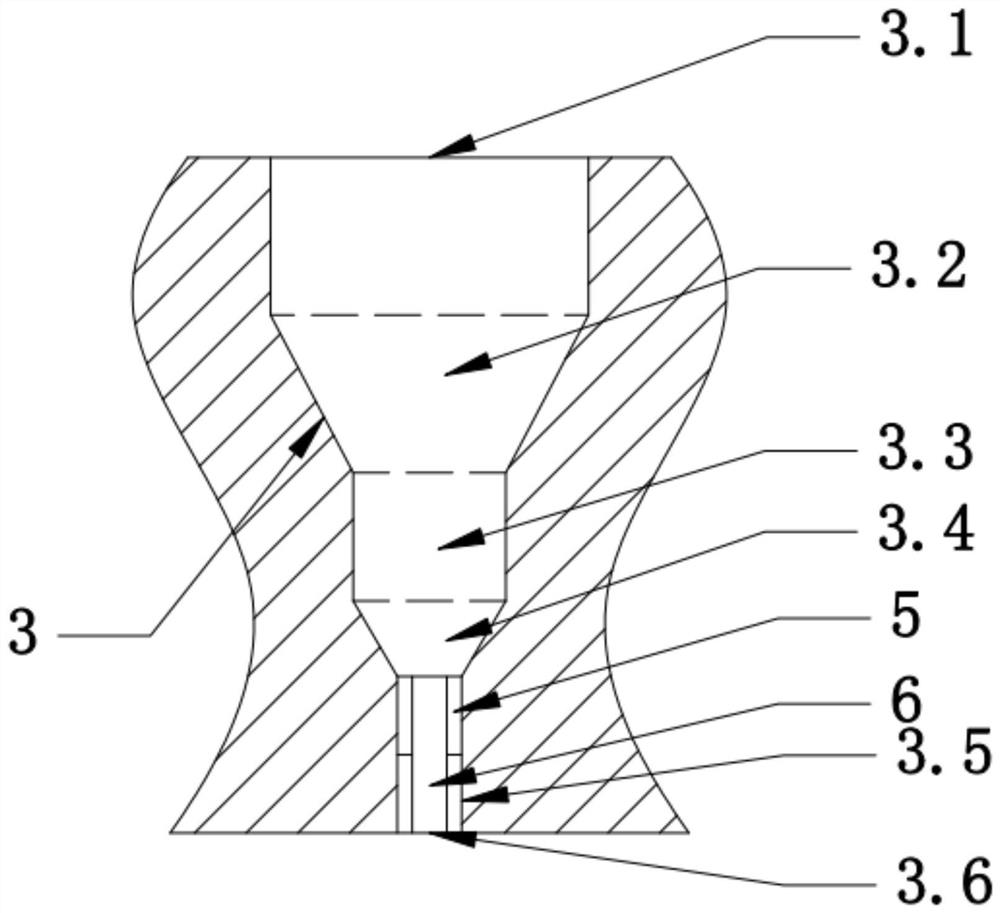

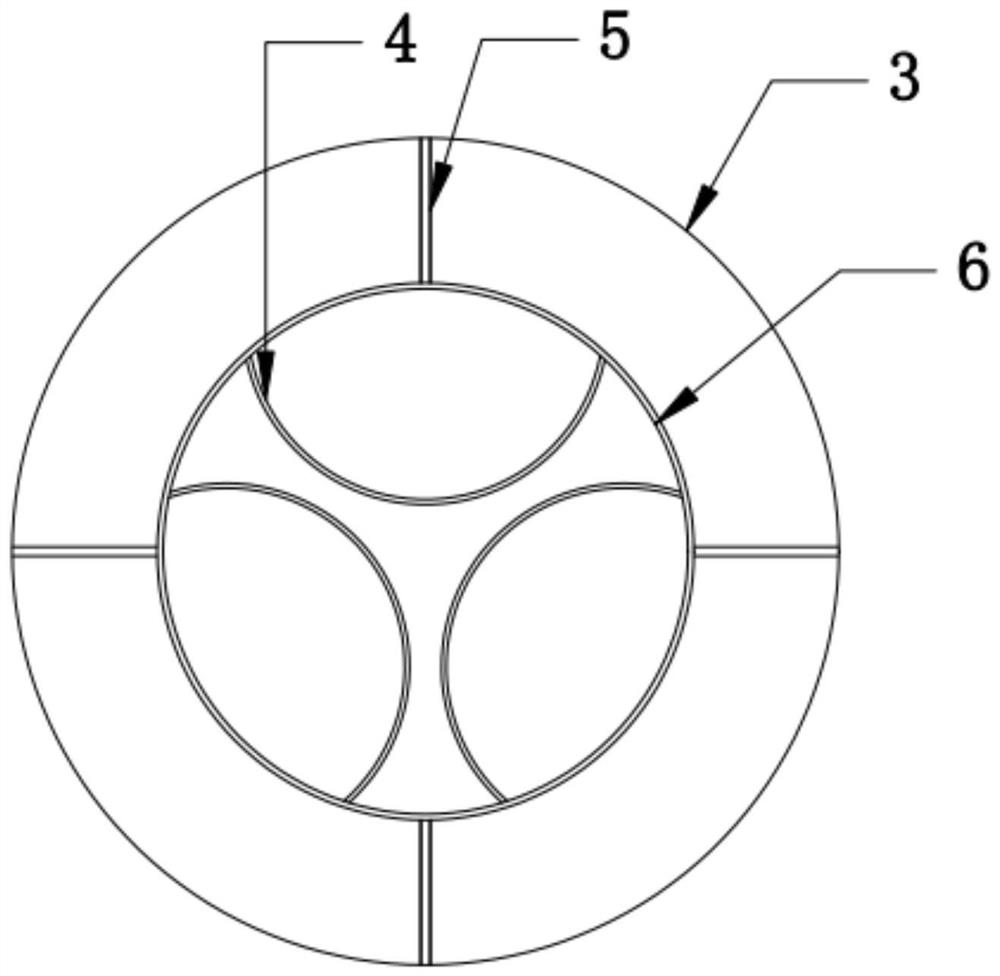

[0017] combined with Figures 1 to 3 , a new type of spinneret for multi-component spinning, including a spinneret body, the spinneret body includes a feed plate 1 and a discharge plate 2, and the discharge plate 2 is provided with several The spinneret hole 3, the spinneret hole 3 is provided with a connecting plate 5, one end of the connecting plate 5 is connected with an annular baffle 6, and the annular baffle 6 is provided with an arc The baffle 4, the end of the spinneret hole 3 close to the feed plate 1 is the feed port 3.1, and the spinneret hole 3 is provided with a first deceleration chamber 3.2, below the first deceleration chamber 3.2 A buffer cavity 3.3 is provided, a second deceleration cavity 3.4 is arranged below the buffer cavity 3.3, a forming cavity 3.5 is arranged below the second deceleration cavity 3.4, and the bottom of the forming cavity 3.5 is a wire outlet 3.6.

[0018] The spinneret holes 3 on the discharge plate 2 are evenly distributed on a plura...

Embodiment 2

[0024] combined with Figures 1 to 3 , a new type of spinneret for multi-component spinning, including a spinneret body, the spinneret body includes a feed plate 1 and a discharge plate 2, and the discharge plate 2 is provided with several The spinneret hole 3, the spinneret hole 3 is provided with a connecting plate 5, one end of the connecting plate 5 is connected with an annular baffle 6, and the annular baffle 6 is provided with an arc The baffle 4, the end of the spinneret hole 3 close to the feed plate 1 is the feed port 3.1, and the spinneret hole 3 is provided with a first deceleration chamber 3.2, below the first deceleration chamber 3.2 A buffer cavity 3.3 is provided, a second deceleration cavity 3.4 is arranged below the buffer cavity 3.3, a forming cavity 3.5 is arranged below the second deceleration cavity 3.4, and the bottom of the forming cavity 3.5 is a wire outlet 3.6.

[0025] The spinneret holes 3 on the discharge plate 2 are evenly distributed on a plura...

Embodiment 3

[0031] combined with Figures 1 to 3 , a new type of spinneret for multi-component spinning, including a spinneret body, the spinneret body includes a feed plate 1 and a discharge plate 2, and the discharge plate 2 is provided with several The spinneret hole 3, the spinneret hole 3 is provided with a connecting plate 5, one end of the connecting plate 5 is connected with an annular baffle 6, and the annular baffle 6 is provided with an arc The baffle 4, the end of the spinneret hole 3 close to the feed plate 1 is the feed port 3.1, and the spinneret hole 3 is provided with a first deceleration chamber 3.2, below the first deceleration chamber 3.2 A buffer cavity 3.3 is provided, a second deceleration cavity 3.4 is arranged below the buffer cavity 3.3, a forming cavity 3.5 is arranged below the second deceleration cavity 3.4, and the bottom of the forming cavity 3.5 is a wire outlet 3.6.

[0032] The spinneret holes 3 on the discharge plate 2 are evenly distributed on a plura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com