Direct writing printing method of Nafion hollow tube structure

A hollow structure and hollow tube technology, applied in the field of 3D printing, can solve the problems of unfavorable hollow Nafion tube structure parameters diversified manufacturing, unfavorable promotion and application, etc., and achieve the effect of rapid manufacturing and moderate dissolution speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

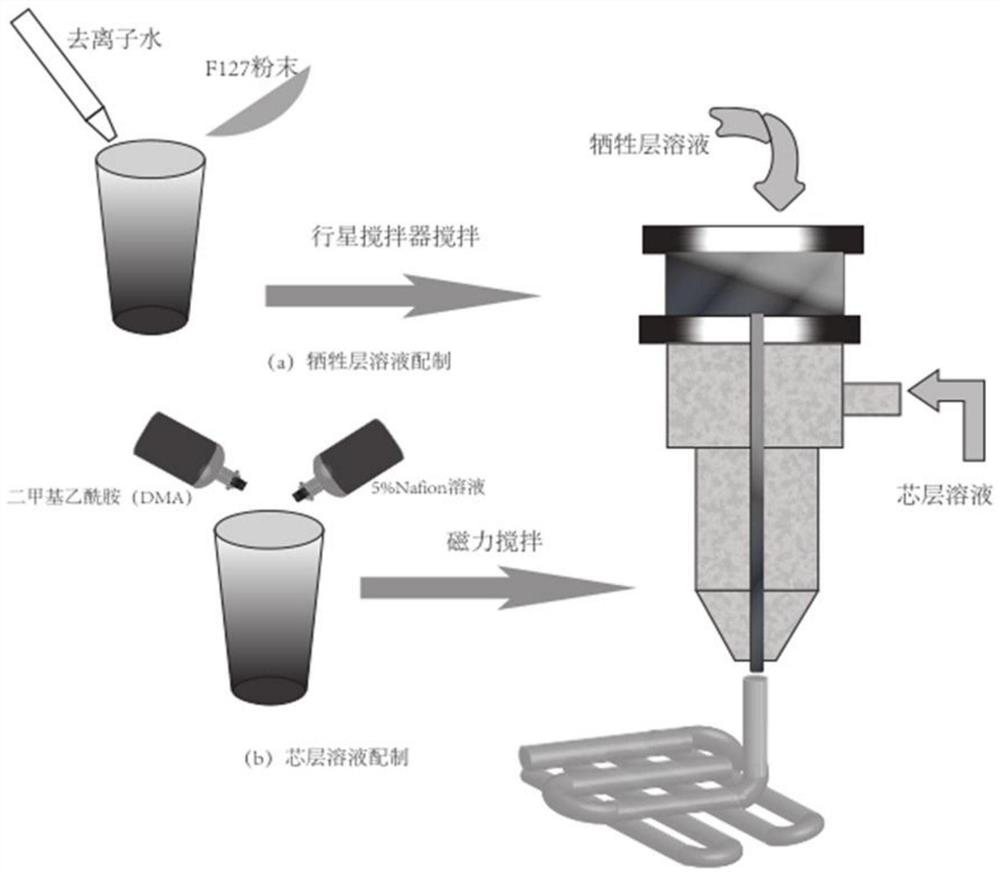

[0056] S1. Set the mass ratio of the ionic polymer solution Nafion with a mass fraction of 25% to dimethylacetamide (DMA) at 1:1, set the magnetic stirrer at 60°C, the rotational speed at 800rpm / min, and the stirring time for 7 hours , to obtain Nafion matrix 3D printing ink with a concentration of 45%;

[0057] S2. Mix the poloxamer (F127) powder with a mass ratio of 1:2.5 and deionized water, and rotate and stir with a planetary mixer at a speed of 2000rpm / min for 30min to obtain a colorless transparent gel-like sacrificial layer printing ink;

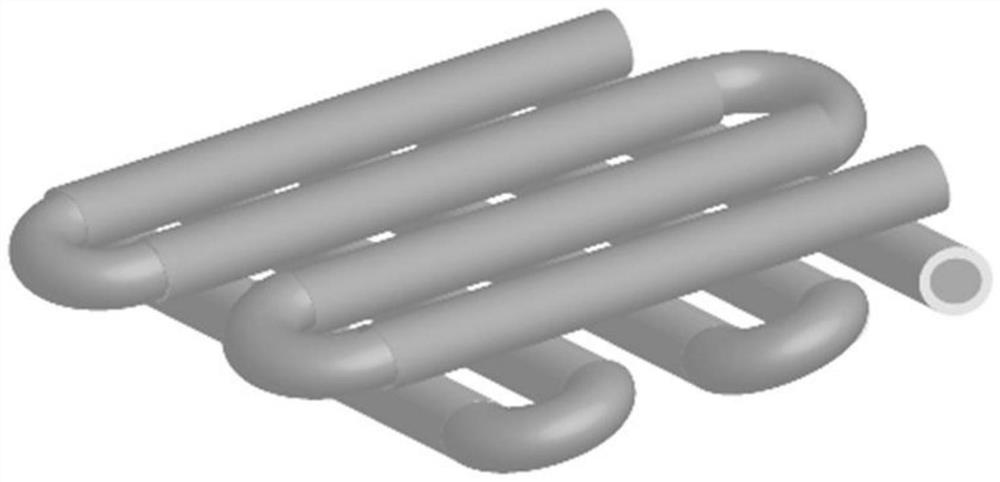

[0058] S3. First, put the Nafion matrix 3D printing ink and the sacrificial layer printing ink into the direct-writing printer with coaxial printing, adjust the extrusion pressure of the Nafion matrix 3D printing ink and the sacrificial layer printing ink respectively, and the Nafion matrix 3D printing ink. Extrusion pressure is P nafion =0.3MPa, the matching air pressure of the sacrificial layer printing ink is 0.3P nafion , so th...

Embodiment 2

[0061] Example 2S1, the mass ratio of the ionic polymer solution Nafion with a mass fraction of 22% and dimethylacetamide (DMA) is 1:2.5, the magnetic stirrer is set at 45°C, the rotating speed is 900rpm / min, and the stirring time is After 7 hours, Nafion matrix 3D printing ink with a concentration of 45% was obtained;

[0062] S2. Mix the poloxamer (F127) powder with a mass ratio of 1:2.75 and deionized water, and rotate and stir with a planetary mixer at a speed of 2000rpm / min for 30min to obtain a colorless transparent gel-like sacrificial layer printing ink;

[0063] S3. First, put the Nafion matrix 3D printing ink and the sacrificial layer printing ink into the direct-writing printer with coaxial printing, adjust the extrusion pressure of the Nafion matrix 3D printing ink and the sacrificial layer printing ink respectively, and the Nafion matrix 3D printing ink. Extrusion pressure is P nafion =0.3MPa, the matching air pressure of the sacrificial layer printing ink is 0.0...

Embodiment 3

[0067] S1. Set the mass ratio of the ionic polymer solution Nafion with a mass fraction of 20% to dimethylacetamide (DMA) at 1:3, set the magnetic stirrer at 60°C, rotate at 800rpm / min, and stir for 8 Hours, the Nafion matrix 3D printing ink with a concentration of 45% was obtained;

[0068] S2. Mix the poloxamer (F127) powder with a mass ratio of 1:3 and deionized water, and rotate and stir with a planetary mixer at a speed of 2000rpm / min for 30min to obtain a colorless transparent gel-like sacrificial layer printing ink;

[0069] S3. First, put the Nafion matrix 3D printing ink and the sacrificial layer printing ink into the direct-writing printer with coaxial printing, adjust the extrusion pressure of the Nafion matrix 3D printing ink and the sacrificial layer printing ink respectively, and the Nafion matrix 3D printing ink. Extrusion pressure is P nafion =0.6MPa, the matching air pressure of the sacrificial layer printing ink is 0.5P nafion , so that the extrusion air pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com