Novel precise 3D printer

A 3D printer and printer technology, applied in the direction of additive processing, etc., can solve the problems of adjusting the forming accuracy and printing speed of 3D printers, vibration, affecting the quality of 3D models, etc., to improve printing accuracy, reduce friction, and work smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

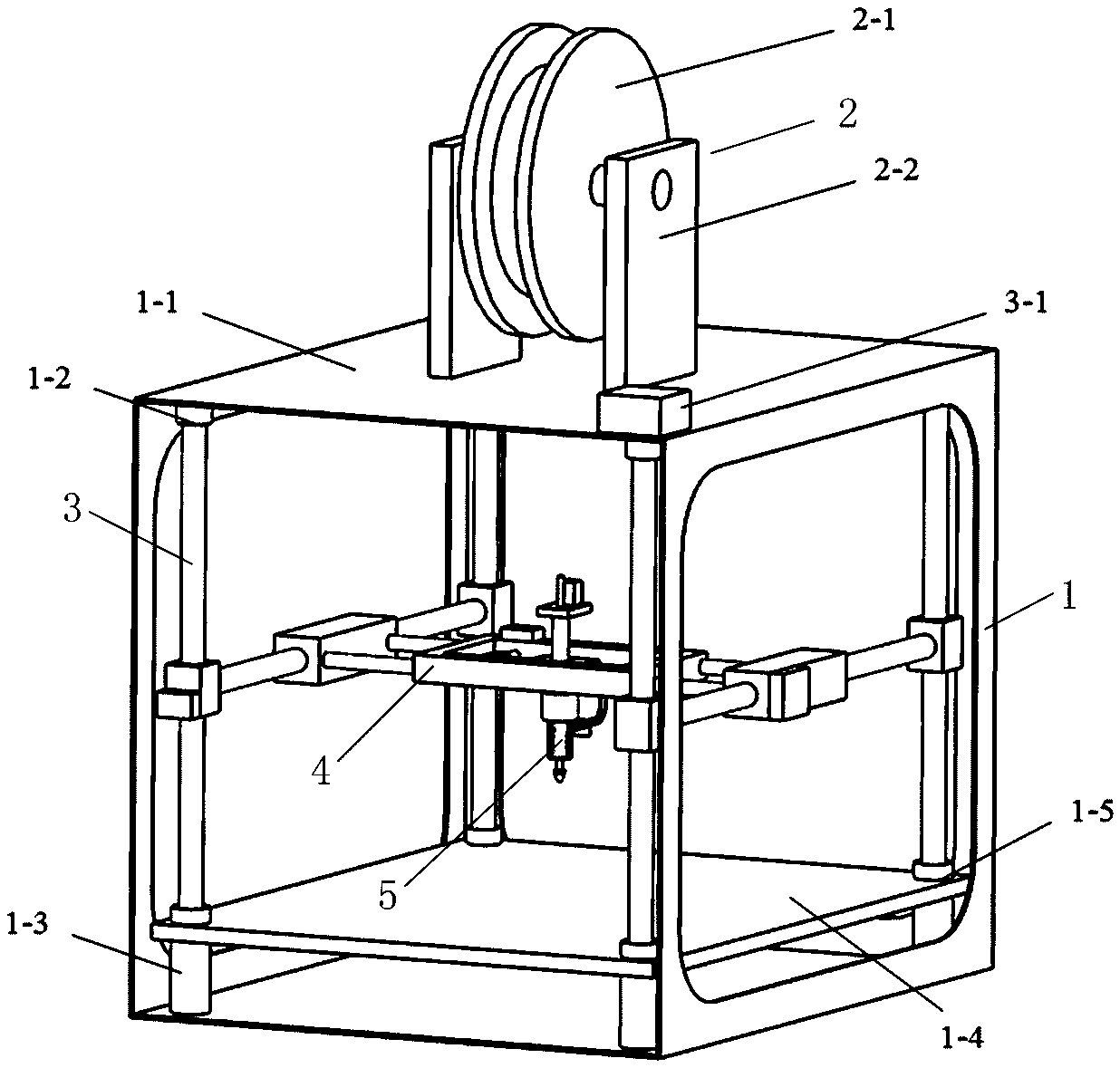

[0047] A new type of precision 3D printer includes a support mechanism (1), a feeding mechanism (2), a first-level movement mechanism (3), a second-level movement mechanism (4) and a nozzle mechanism (5);

[0048]A supporting mechanism (1), used to support the whole and formed products of the 3D printer;

[0049] The feeding mechanism (2) is used to store and provide the filaments required by the 3D printer for printing products;

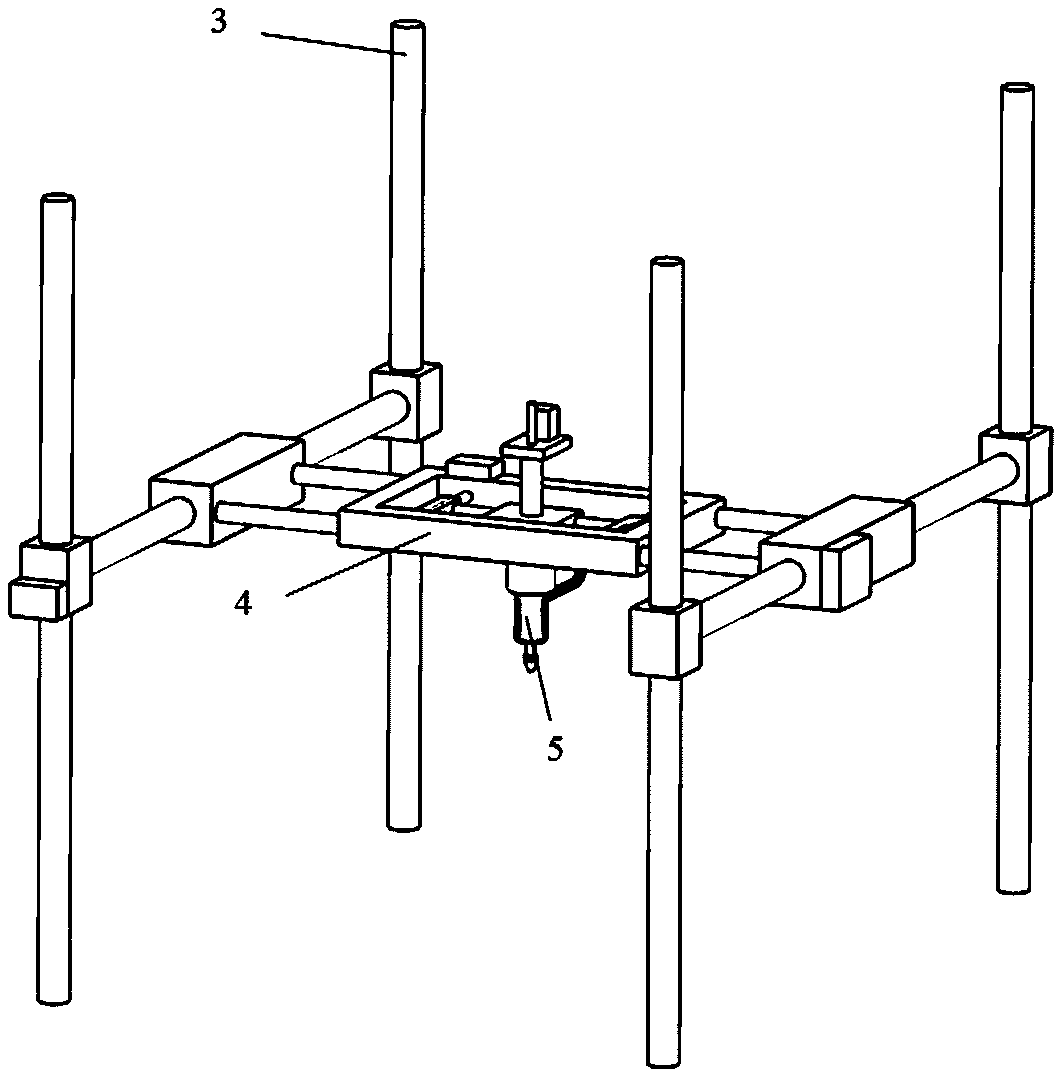

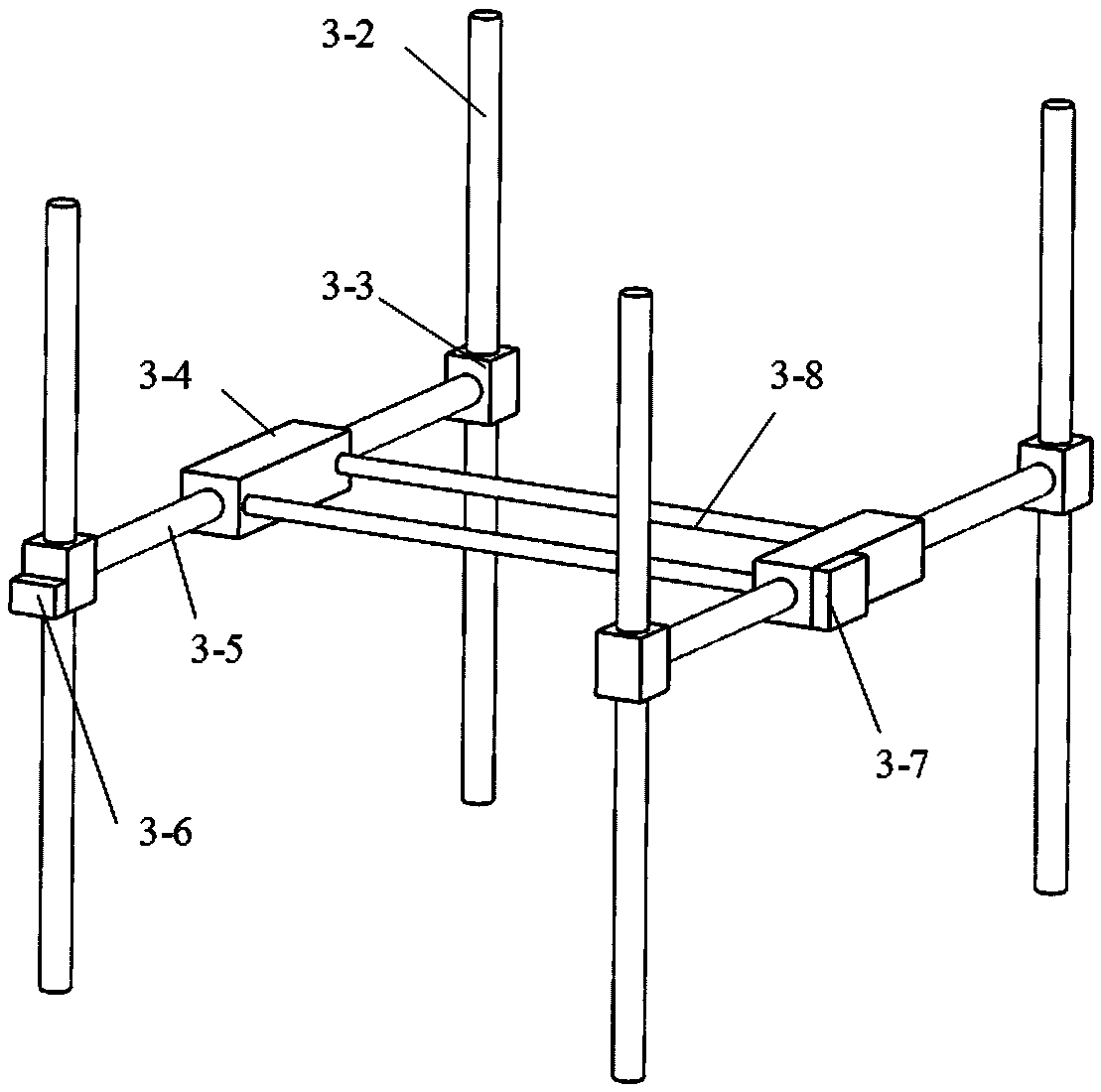

[0050] The first-level motion mechanism (3) and the second-level motion mechanism (4) are used to drive the nozzle for printing movement;

[0051] The nozzle mechanism (5) is used to melt and extrude the filament, and at the same time, it can cool the formed part of the product.

[0052] The support mechanism (1) includes a printer casing (1-1), a first-stage Z-direction screw upper support (1-2), a working platform s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com