Flip chip bonding apparatus and flip chip bonding method

A bonding device and flip-chip technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problem of reduced reliability and accuracy of the bonding process, inability to accurately obtain semiconductor chips, and transfer positions Reduced accuracy and other issues, to achieve the effect of improving UPH, reducing thermal expansion and vibration, and reducing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

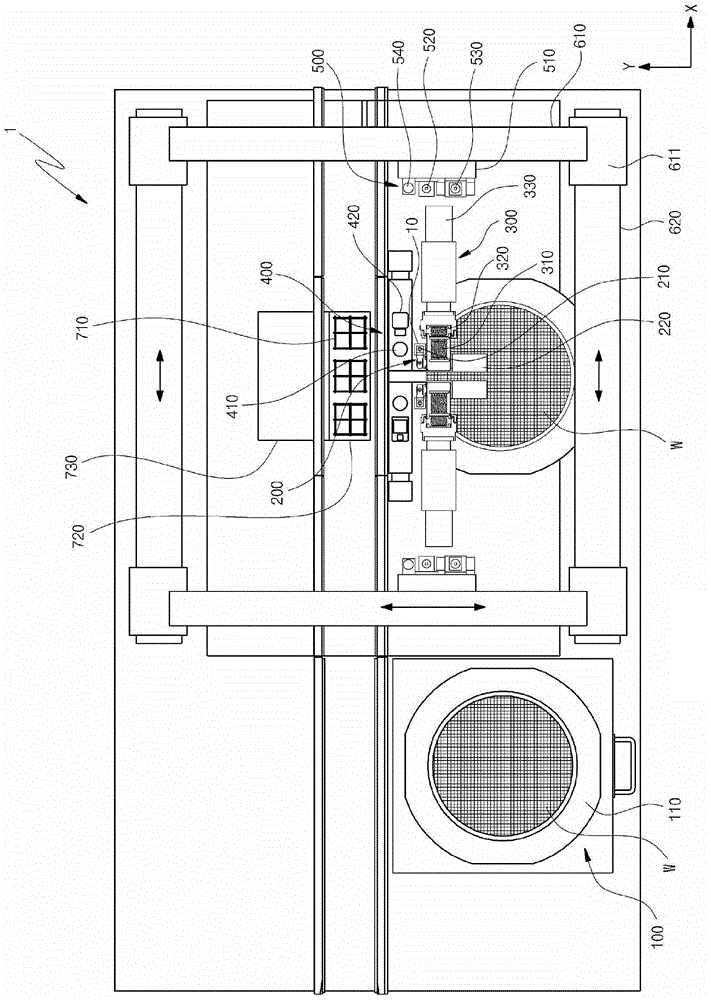

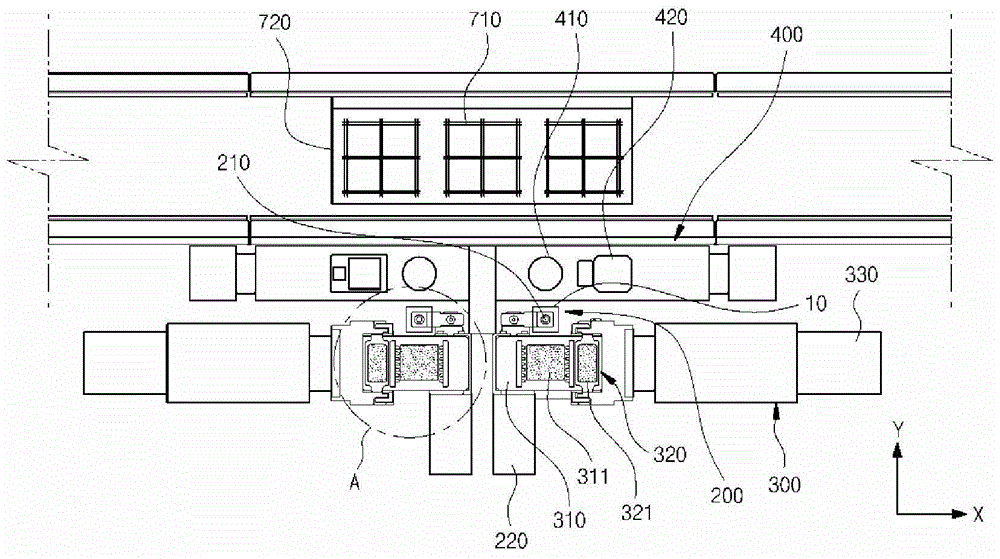

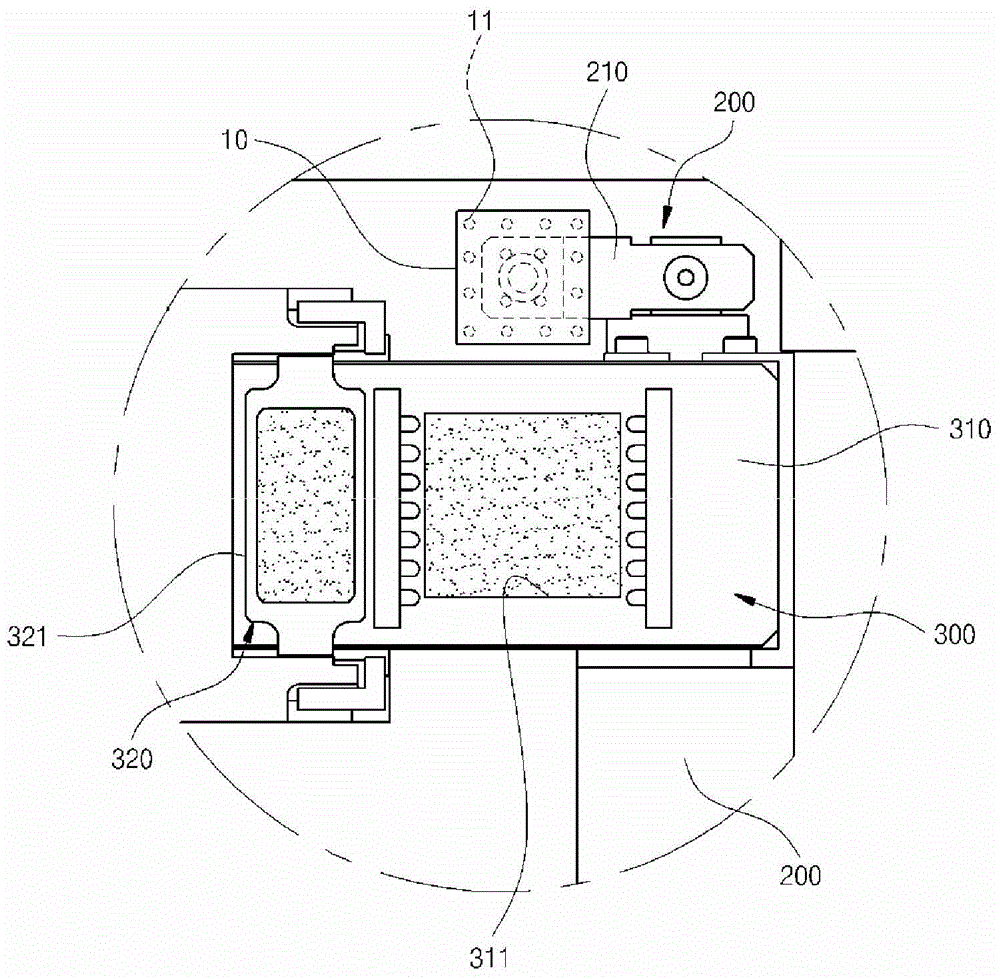

[0068] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The embodiments described below are provided as examples capable of conveying the idea of the present invention to those skilled in the art. The present invention is not limited to the embodiments described below and may be embodied in other ways. In order to clearly describe the present invention, parts irrelevant to the description may be omitted in the drawings, and the sizes of constituent elements, etc. may be enlarged for easy understanding.

[0069] The flip chip bonding process is to use a sawing machine to cut a wafer into a plurality of semiconductor chips (flip chips 10 ), absorb each semiconductor chip, and mount the flip chips 10 on the substrate 710 to be mounted. Process on the bonding site (mounting area) of each semiconductor chip.

[0070] Generally, the bonding process of a flip chip includes the following processes: a process in which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com