A probe test device for an electronic module

A technology for testing devices and electronic modules, which is applied in the directions of measuring devices, measuring device casings, components of electrical measuring instruments, etc., to meet production requirements, the device structure is simple, and the production capacity is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

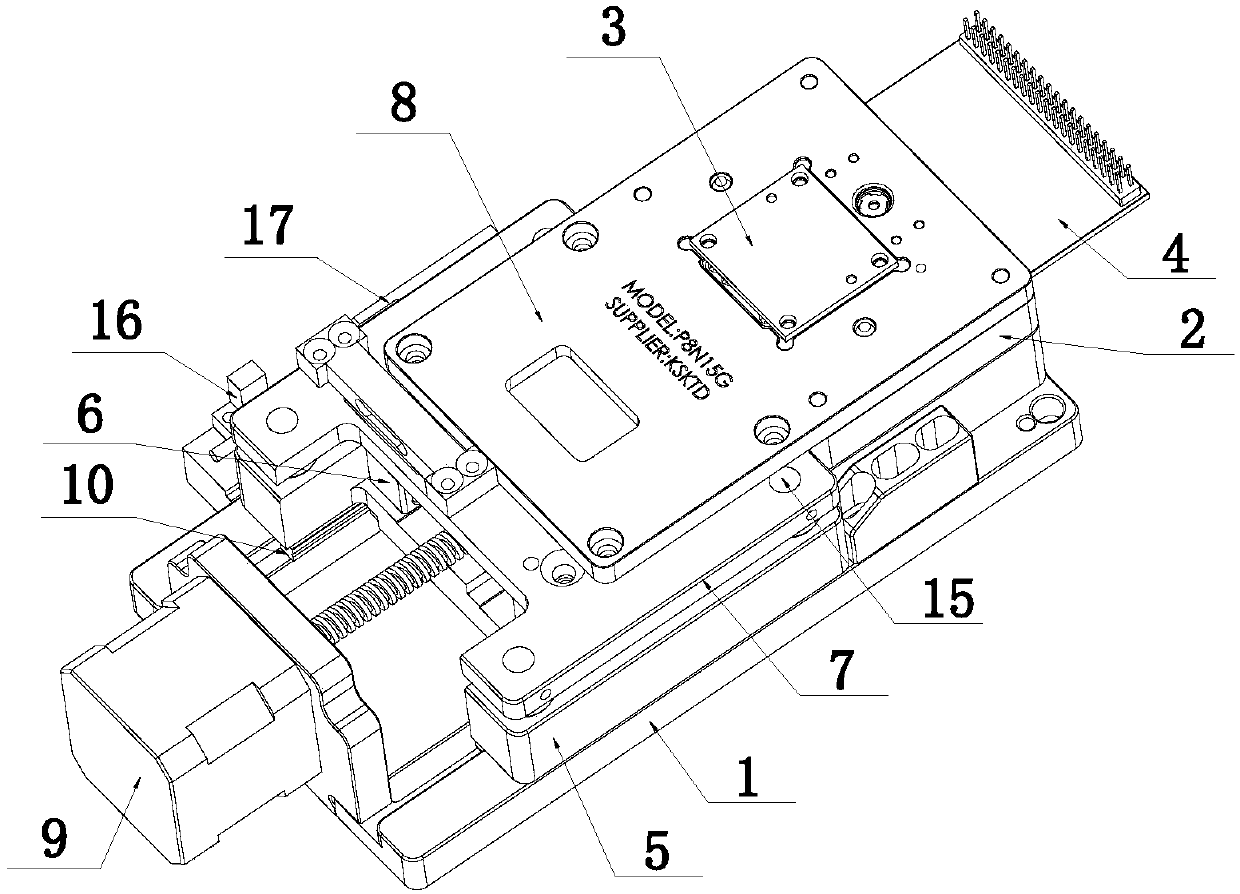

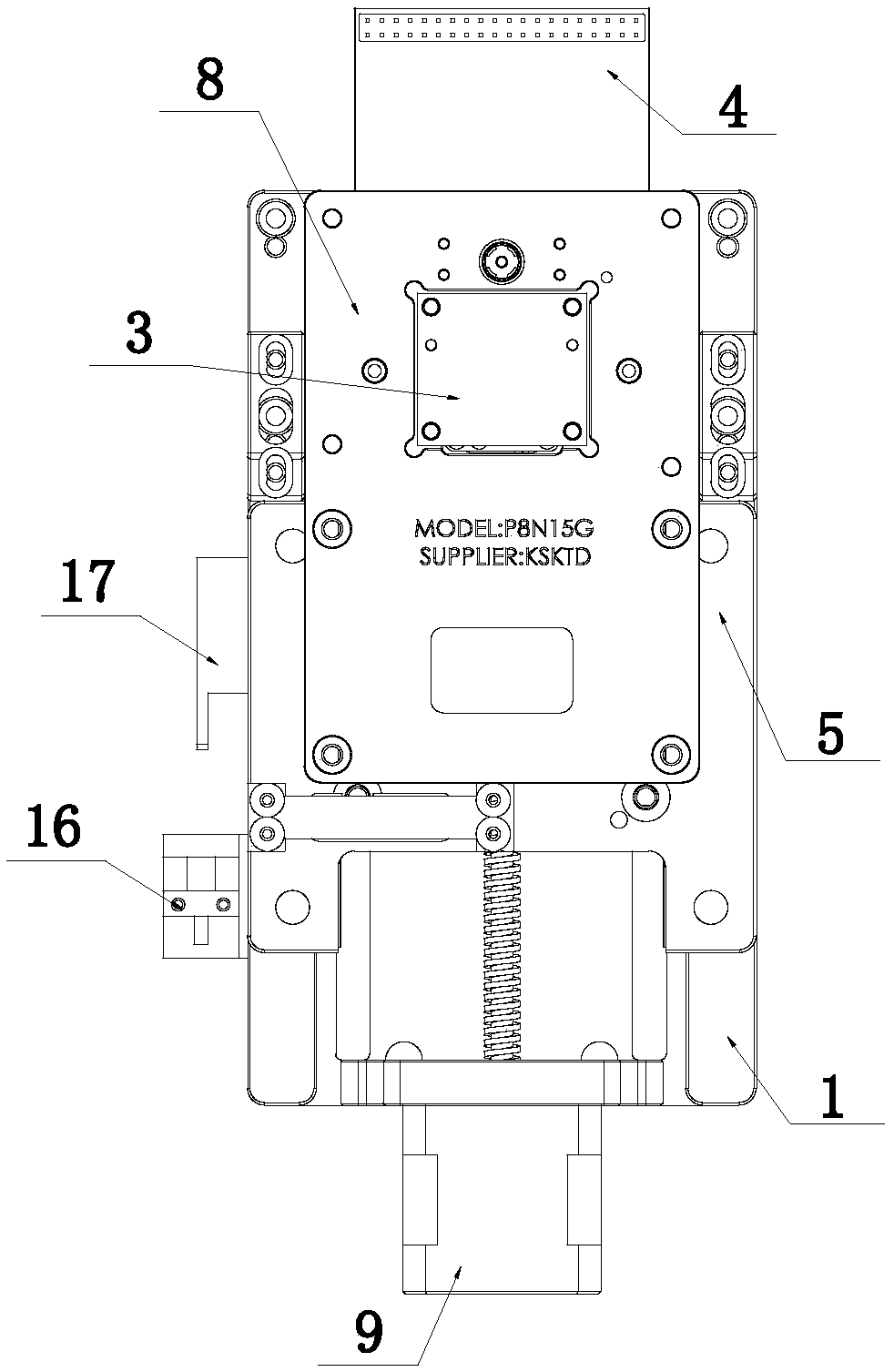

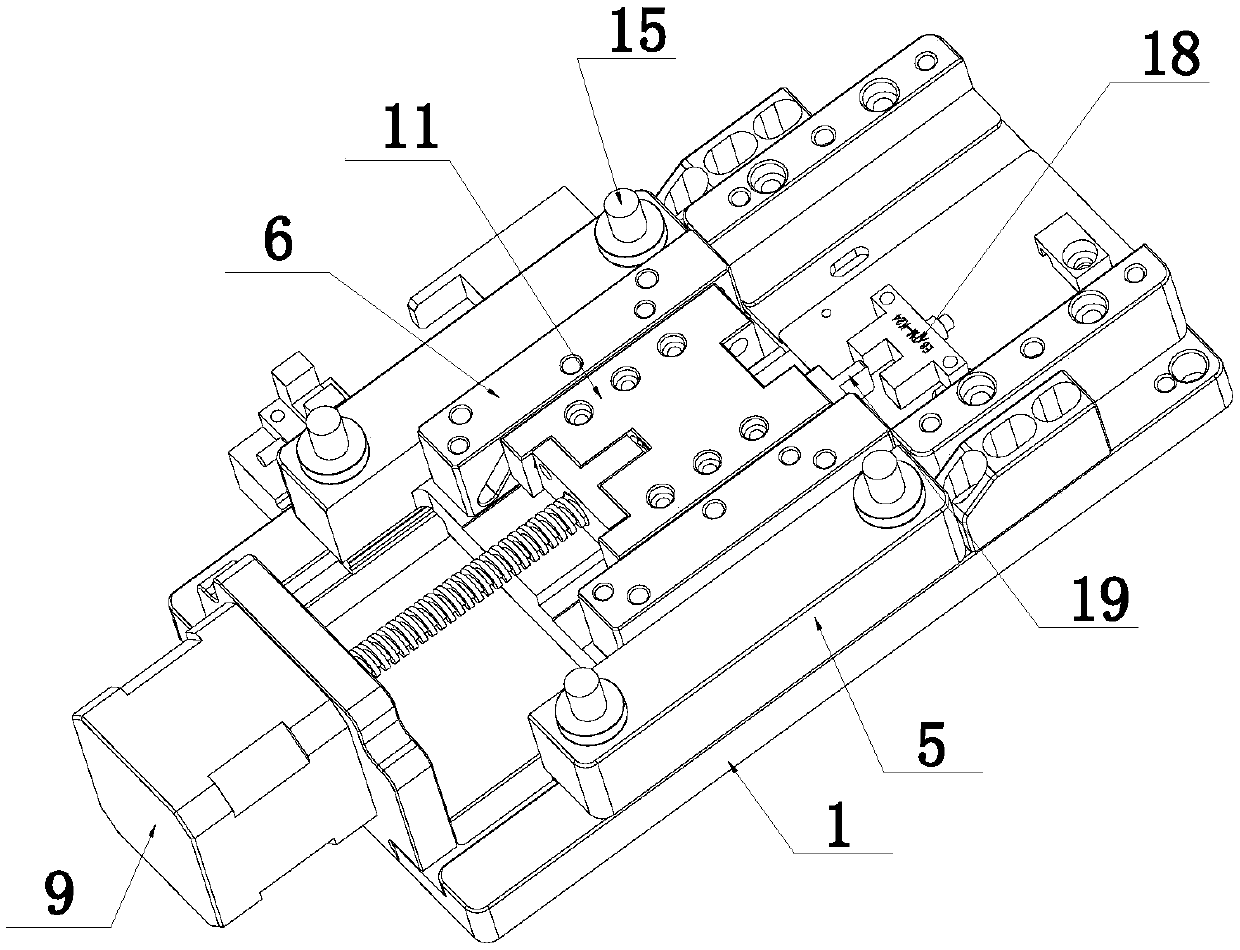

[0029] Such as figure 1 , figure 2 A probe test device for an electronic module shown, the probe test device includes a base 1, a test module and a fixture module, the test module and the fixture module are all arranged on the base 1, and the fixture module connects the electronic module Fixed testing in the test module. Such as figure 1 , Figure 7 As shown, the test module includes a test seat 2, a first circuit board 3 and a second circuit board 4, the test seat 2 is provided with a module fixing port 21, and the two sides of the module fixing port 21 are respectively provided with Mark points. And on the test socket 2, the first pin holder 22 is also fixed, the first pin holder 22 is provided with the first pin, the first pin connection is provided with a lower contact point, and the lower contact point is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com