Melt-blown cloth mold with multi-row-hole spray head

A technology of melt-blown cloth and mold, which is applied in the direction of spinneret assemblies, non-woven fabrics, textiles, and papermaking, and can solve problems such as high cost of use, poor stability and uniformity of silk output, and low efficiency of cloth output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

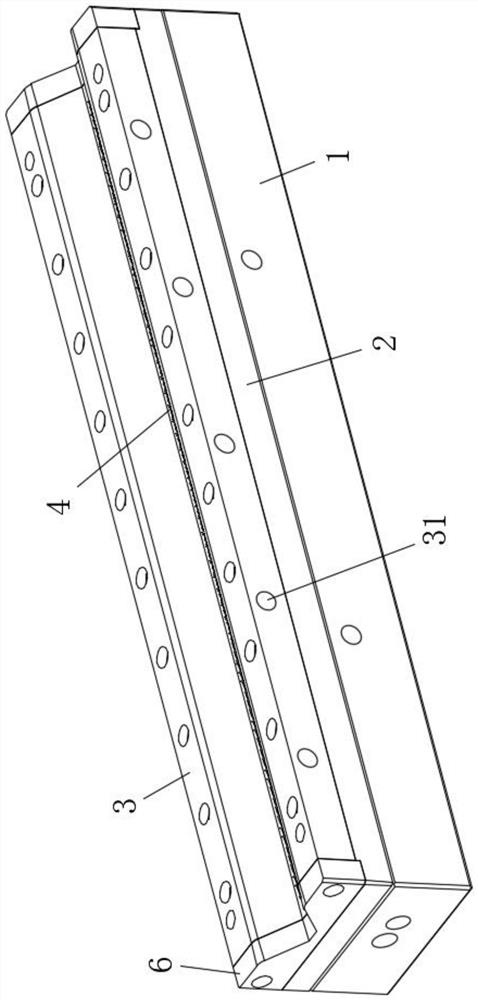

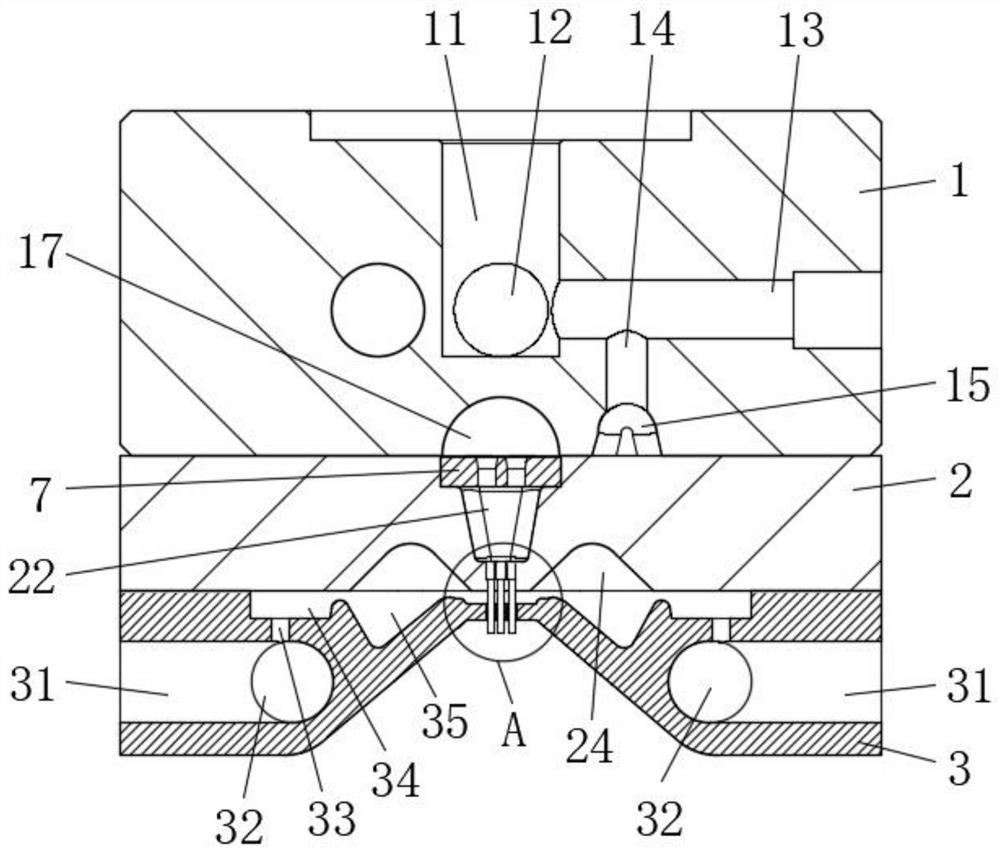

[0031] Such as figure 1 , figure 2 As shown, a melt-blown cloth mold with multiple rows of nozzles, the melt-blown cloth mold includes a feed plate 1, a spinneret 2, and an air-regulating plate 3 from top to bottom, and the feed plate 1 and the air-regulating plate 3 are respectively Connect with spinneret 2 with screws.

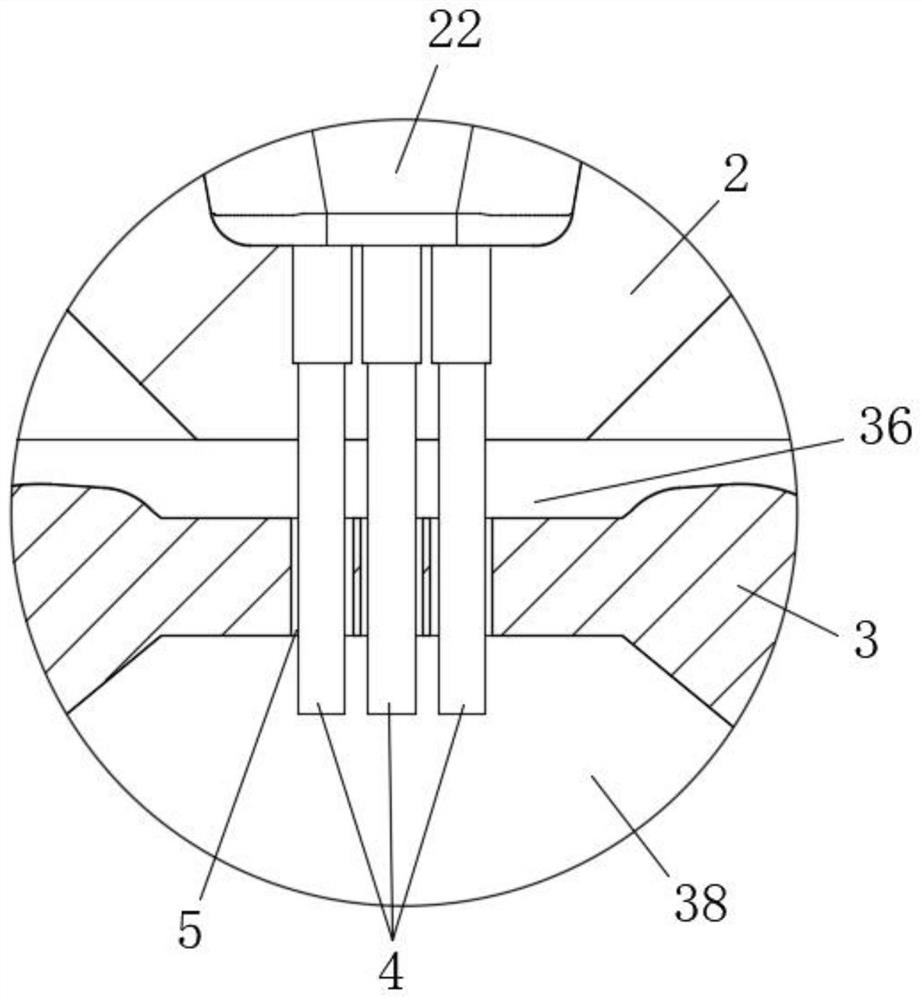

[0032] Such as figure 1 , figure 2 , Figure 4 As shown, the top center of the feed plate 1 is provided with a feed hole 11, and the bottom of the feed plate is provided with a strip-shaped distribution groove 17 arranged along its length direction, and the feed plate 1 is provided with a connected feed hole 11 and The feed channel of distribution tank 17,

[0033] specific as figure 2 , Figure 4 , Figure 5 , Figure 6 As shown, the feed plate 1 is provided with a main feed pipe 12 arranged along its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com