A kind of processing system and processing method of ultrafine grinding wire

An ultra-fine grinding and processing system technology, applied in metal processing equipment, sustainable manufacturing/processing, grinding devices, etc., can solve the problems of ultra-fine grinding wire disconnection, affecting processing efficiency, and difficulty in searching, so as to avoid material Uneven mixing, improved processing efficiency, smooth and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and should not be construed as limiting the protection scope of the application. Those skilled in the art can The above application content makes some non-essential improvements and adjustments to this application.

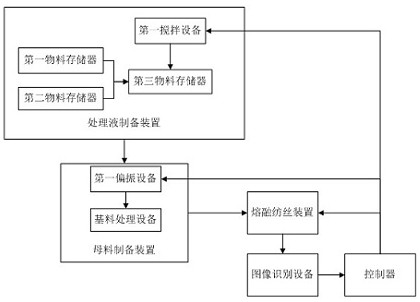

[0028] like figure 1 As shown, it is a schematic diagram of the processing system of the ultrafine abrasive wire of the present invention.

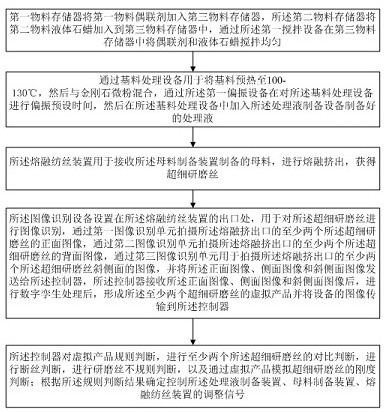

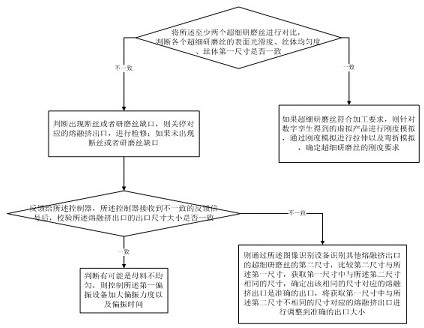

[0029]The invention discloses a processing system for ultra-fine grinding filaments, comprising: a treatment liquid preparation device, a master batch preparation device, a melt spinning device, an image recognition device and a controller. The treatment liquid preparation device includes a first stirring device, The first material storage, the second material storage and the third material stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com