A 3D printing smart nozzle

A 3D printing and intelligent technology, which is applied in the field of 3D printing intelligent nozzles, can solve the problems of failing to meet printing accuracy requirements, time-consuming and laborious, and inability to realize the heating and temperature measurement effects of extrusion nozzles, so as to avoid wear and flow smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

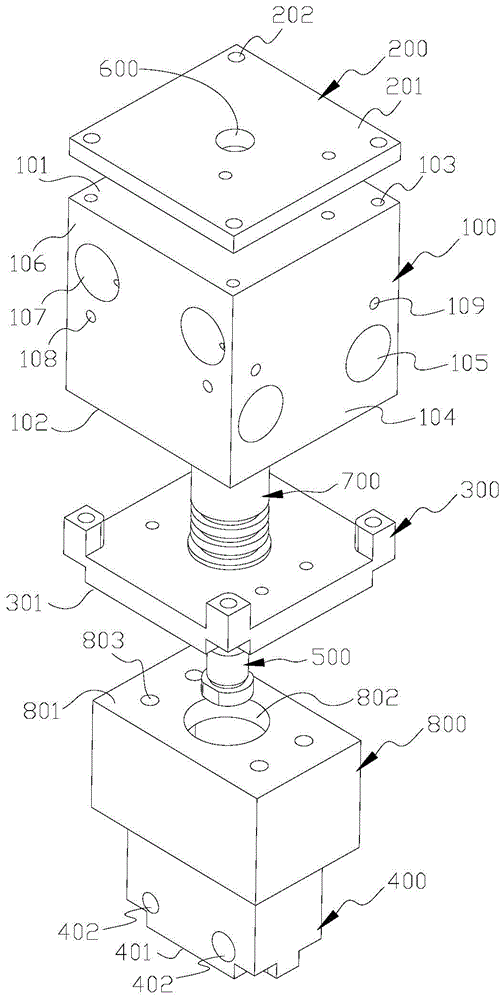

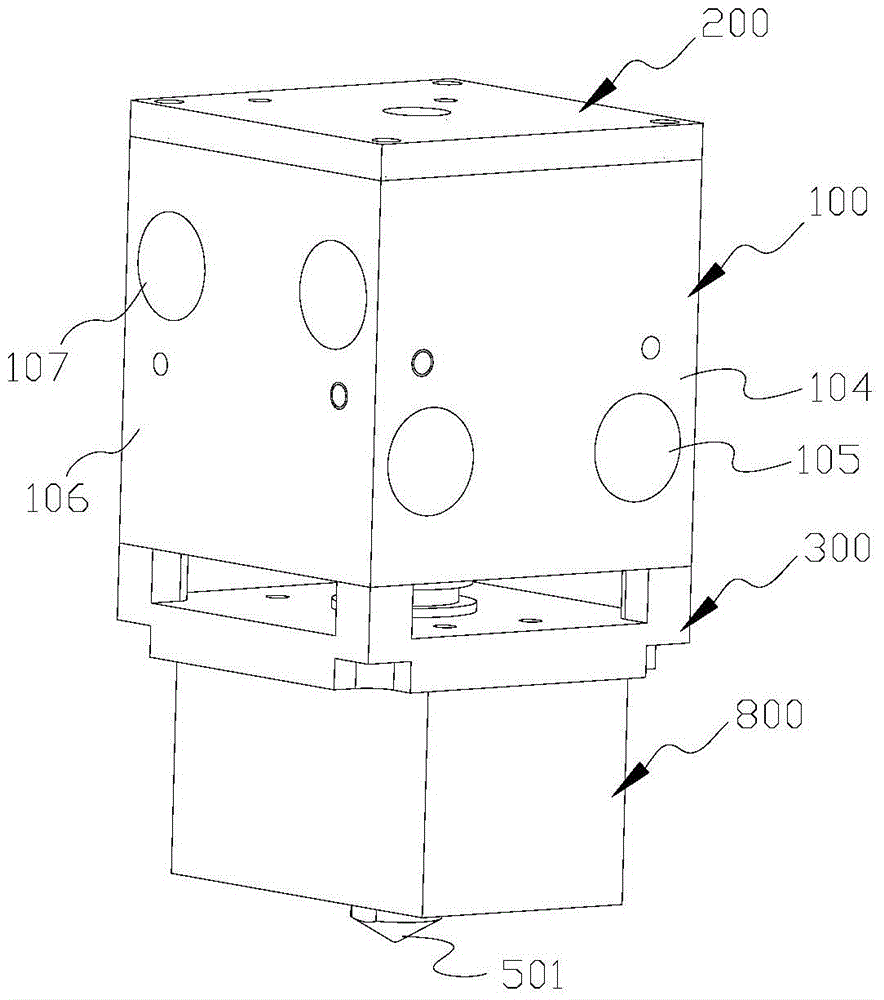

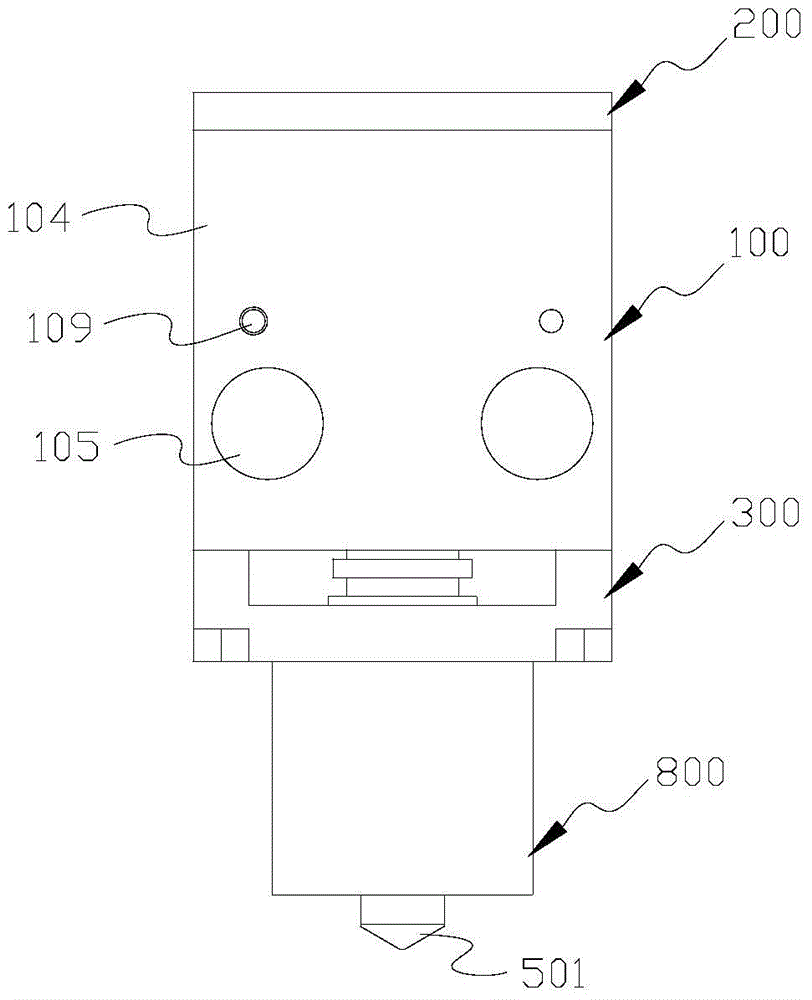

[0026] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0027] Such as figure 1 with figure 2 Shown is a 3D printing intelligent nozzle 10 of the present invention, including a fixed bracket 100, a cover plate 200 installed on the top 101 of the fixed bracket 100, a concave bracket 300 installed on the bottom 102 of the fixed bracket 100, and a concave bracket 300 installed on the concave bracket 100. The heat conduction block 400 and the material guide tube 500 at the bottom 301 of the shaped bracket 300 . In the middle of the cover plate 200 , the fixing bracket 100 , the concave bracket 300 and the heat conduction block 400 , an installation hole 600 for installing the material guide tube 500 is defined along the same vertical line.

[0028] On the top 101 of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com