Preparation method and device for wire extruding mechanism with double spray heads

A technology of double nozzles and nozzles, which is applied in the coating device, additive processing, etc., can solve the problems of unsmooth wire discharge and rough surface of objects, and achieve the effect of smooth wire discharge, high surface quality and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

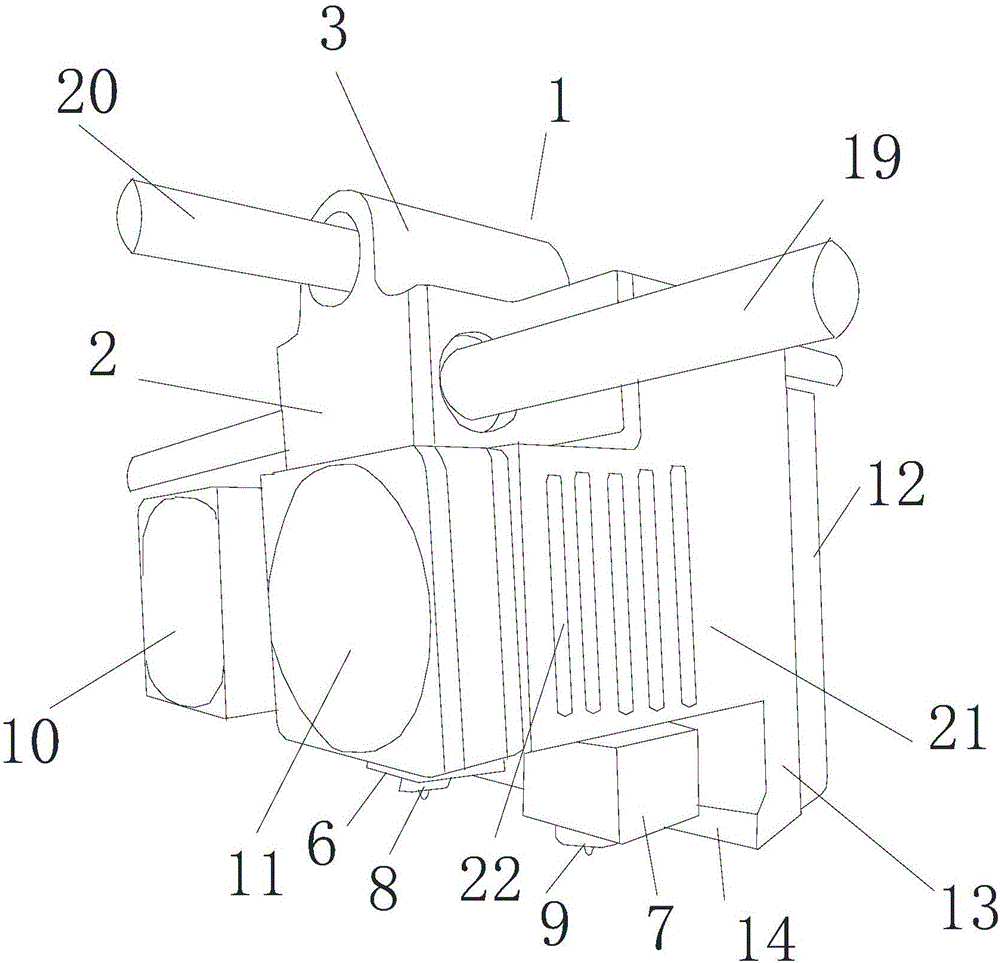

[0034] Example: see Figure 1 to Figure 3 , the present embodiment provides a method for preparing a dual-nozzle wire-out mechanism, which includes the following steps:

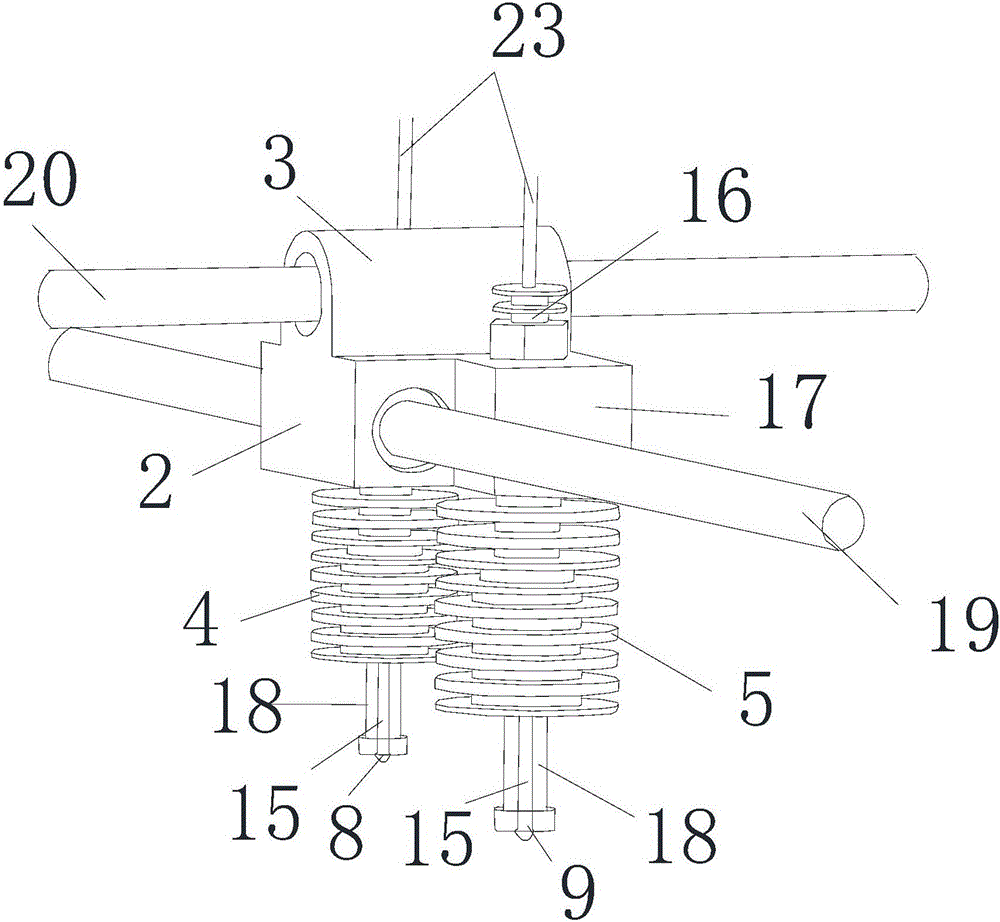

[0035] (1) Prepare the fixed seat 1, set the X-axis slide seat 2 and the Y-axis slide seat 3 on the upper end of the fixed seat 1, and set the first feeding assembly and the second feeding assembly on both sides of the X-axis slide seat 2 and Y-axis slide seat 3 Material components;

[0036] (2) Prepare the first heat dissipation aluminum part 4 and the second heat dissipation aluminum part 5. The heat dissipation aluminum part is composed of a plurality of annular aluminum sheets, and an internal hollow heat conduction column is arranged in the middle of the annular aluminum sheet. The upper diameter of the heat conduction column is less than lower diameter;

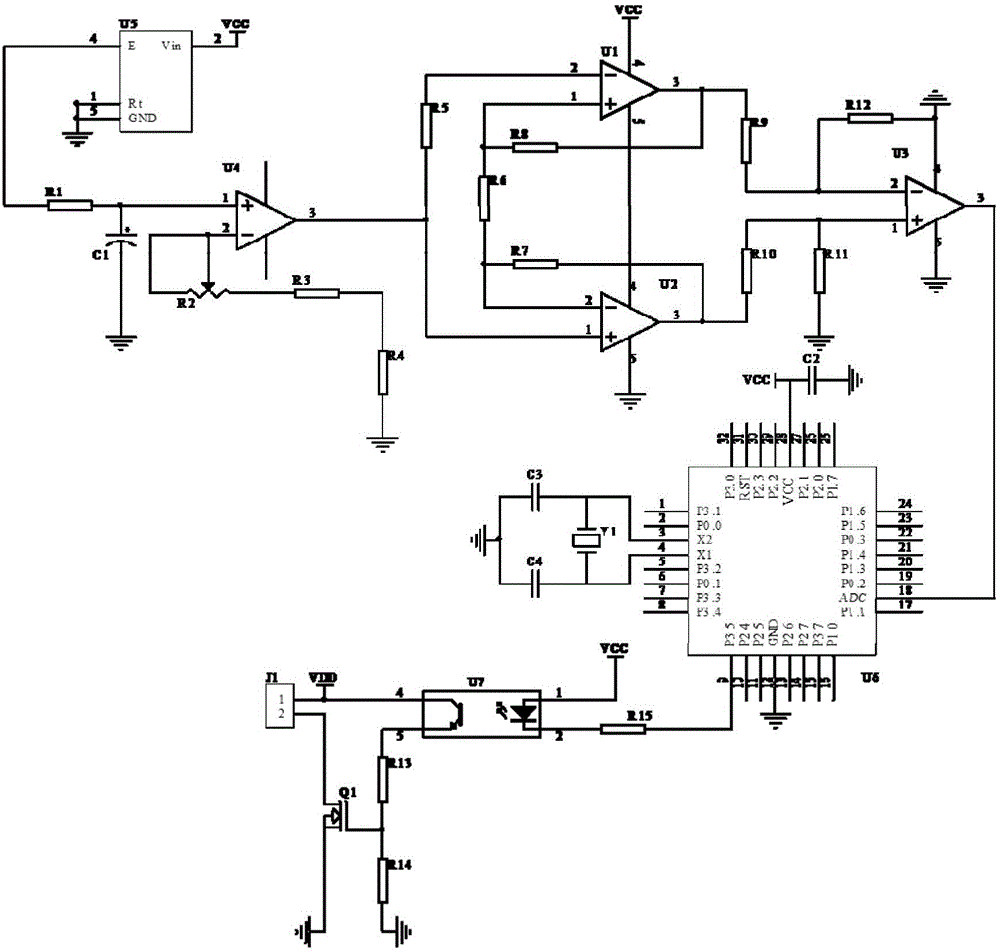

[0037] (3) prepare the first heating aluminum block 6 and the second heating aluminum block 7, be provided with heating device in the heating alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com