Multi-station automatic-adjustment wheel type gel spinning machine

An automatic adjustment, multi-station technology, applied in the direction of wet spinning, etc., can solve the problems of insufficient width, inability to adjust the extrusion speed, high temperature resistance of the active rubber roller and driven rubber roller, etc., and achieve the goal of improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

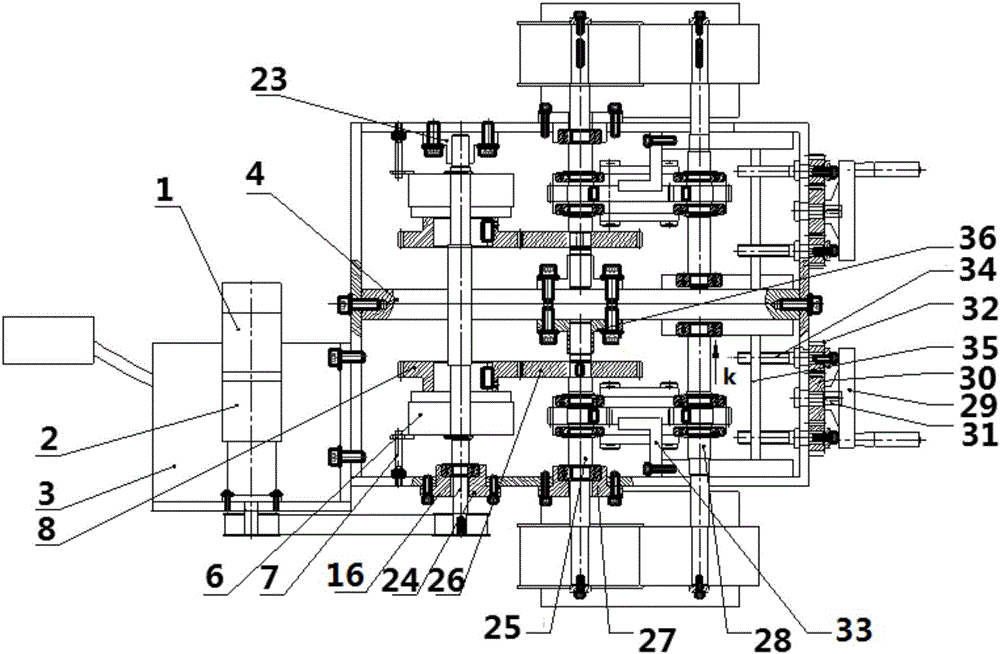

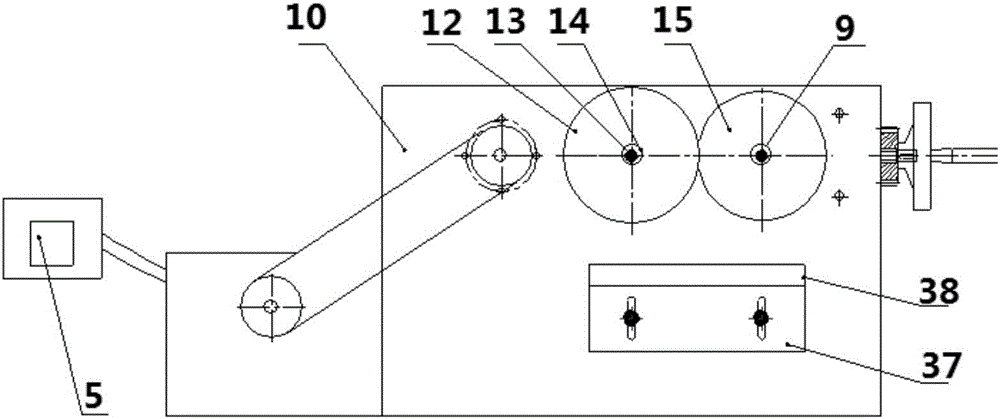

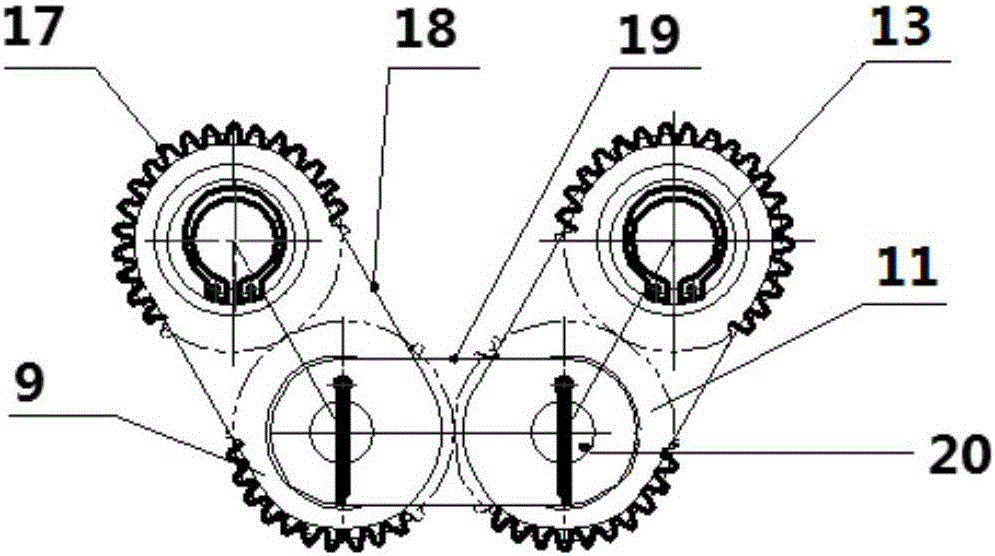

[0033] Such as figure 1 with figure 2 As shown, a multi-station automatic adjustment wheeled gel spinning machine according to the present invention includes a spinning box 10, a power mechanism, a control system 5 and a driven rubber roller position adjustment mechanism. Such as figure 1 As shown, the inside of the spinning box 10 has a cavity, and the spinning box 10 is provided with two mutually fitted bearing support plates 4, and the spinning box 10 is provided with two stations, and the two stations are respectively arranged Between the bearing support plate 4 and the two box walls of the spinning box 10; the two stations have the same structure, including the clutch gear 8, the electromagnetic clutch 6, the driving rubber roller input gear 26, the floating gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com