3D printing material extruder

A 3D printing and material machine technology, applied in the direction of additive processing, etc., can solve the problems of inaccurate motion control of printheads, reduce the inertia of printheads, and large inertia of printheads, and achieve precise motion control, increase flexibility, and reduce inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

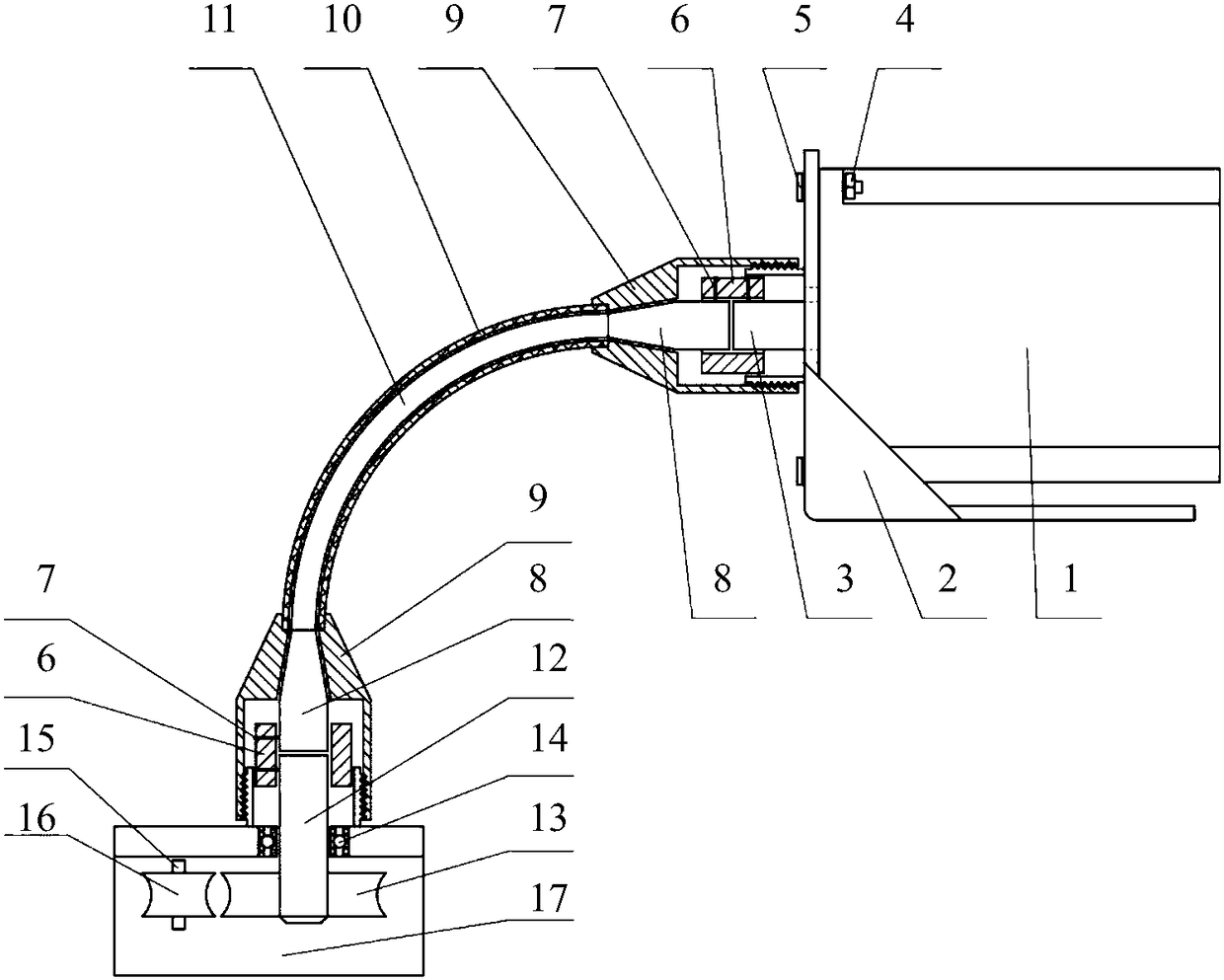

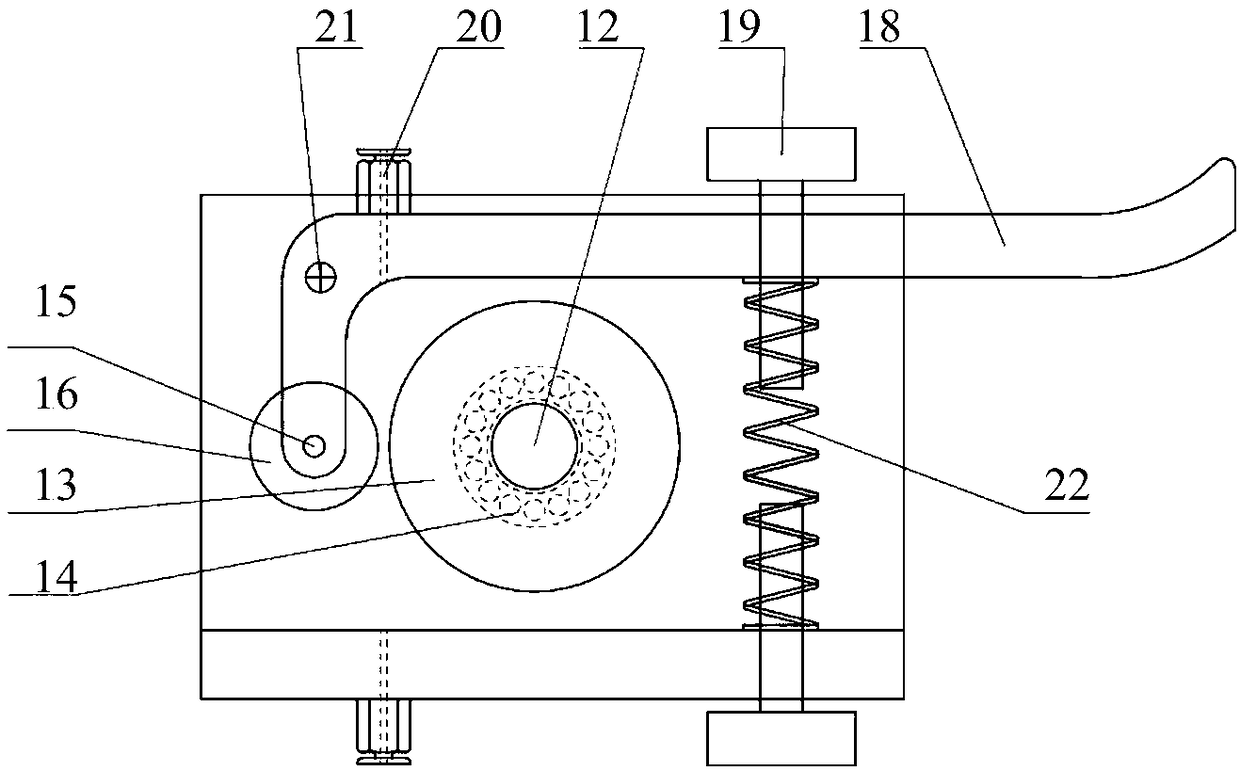

[0029] Such as figure 1 with figure 2 A 3D printing extruder shown includes: a stepping motor 1, a stepping motor mounting bracket 2 for supporting and fixing the stepping motor 1, a shaft core 11 with shaft core joints 8 at both ends, a sleeve As for the shaft sleeve 10 on the shaft core 11, the mounting bracket 17 of the extruding device, the driving wheel 13 rotated by the driving wheel shaft 12 and the mounting bracket 17 of the extruding device, the driven pressing wheel bracket 18, the driven wheel shaft 15 and the slave The driven wheel 16 of dynamic pressing wheel bracket 18 rotation assembly;

[0030] The mandrel is a flexible shaft;

[0031] Wherein, the output shaft 3 of the stepping motor 1 is connected with the shaft core joint 8 at one end of the shaft core 11 through a shaft coupling 6, and is fixed by a set screw 7, and the shaft core joint 8 at the other end of the shaft core 11 is also connected through a coupling. The shaft device 6 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com