Design method for printing ink hole plugging tool

A design method and hole plugging technology, which is applied in the fields of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems such as the high difficulty coefficient of via ink plugging, the inability to improve the plugging ability, and the difficulty in meeting the hole filling requirements, etc. Achieve the effects of shortening the plugging time, improving the plugging efficiency and ensuring the fullness of the plugging hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

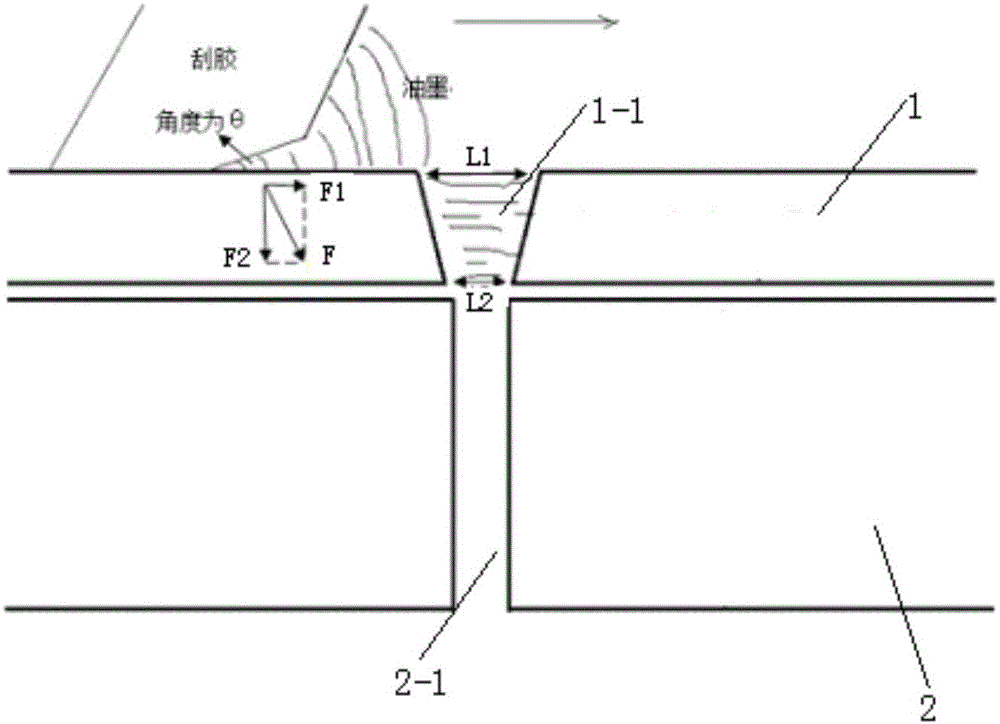

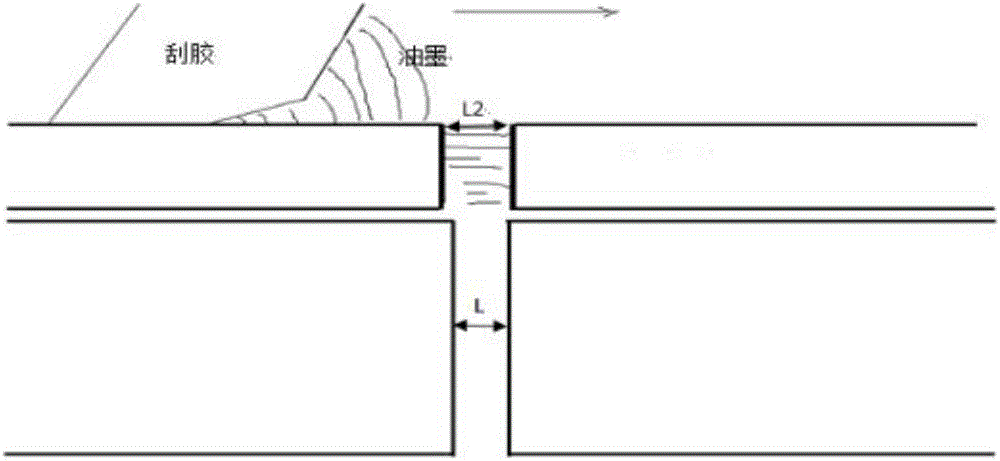

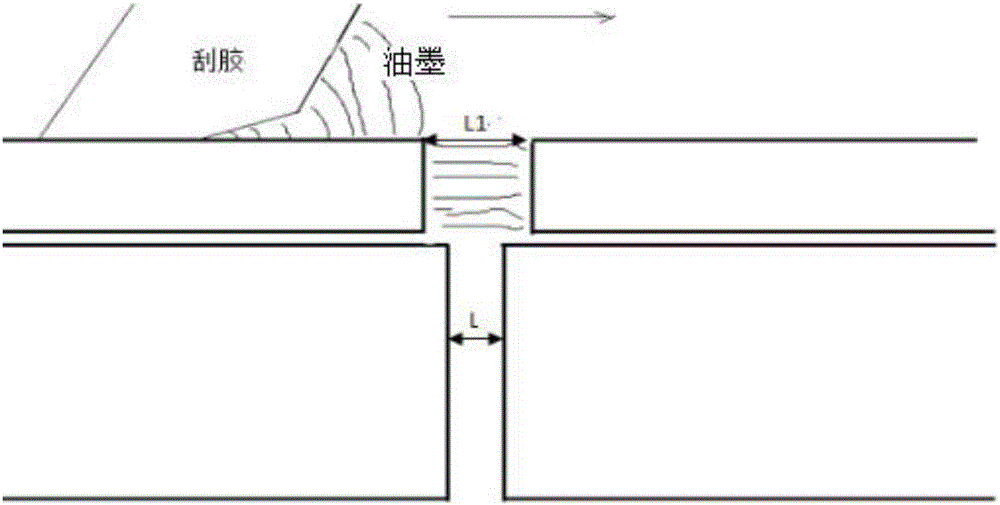

[0019] Refer to attached image 3 In this embodiment, the substrate 1 is placed above the PCB board 2, and an inverted tapered hole 1-1 is opened on the substrate 1. The position of the inverted tapered hole 1-1 is the same as that of the plug hole 2-1 on the PCB board 2. The position is adapted, the size of the lower surface of the inverted tapered hole 1-1 is adapted to the size of the plug hole 2-1, and the inclination F of the axial section of the inverted tapered hole 1-1 2 =F*cosθ, F is the scraper pressure, θ is the 1-1 slope angle of the inverted tapered hole;

[0020] When the squeegee is printed on the inverted tapered hole 1-1, the ink will be pushed into the inverted tapered hole 1-1, and the size of the pushing force is: F 合 -f, F 合 is the resultant force of the support force of the inclined plane and the pressure of the scraper, and f is the friction force;

[0021] Scratch time: t 1 =L 1 / v,t 2 =L 2 / v, then t 1 >t 2 ;t 1 Printing time for cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com