Automatic soldering equipment capable of protecting transformer PINs and soldering method

An automatic welding and transformer technology, which is applied in welding equipment, metal processing equipment, auxiliary equipment, etc., can solve the problems of unguaranteed product quality, low soldering precision, low safety, etc., and achieve the advantages of automatic operation stability and structure Reasonable design and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

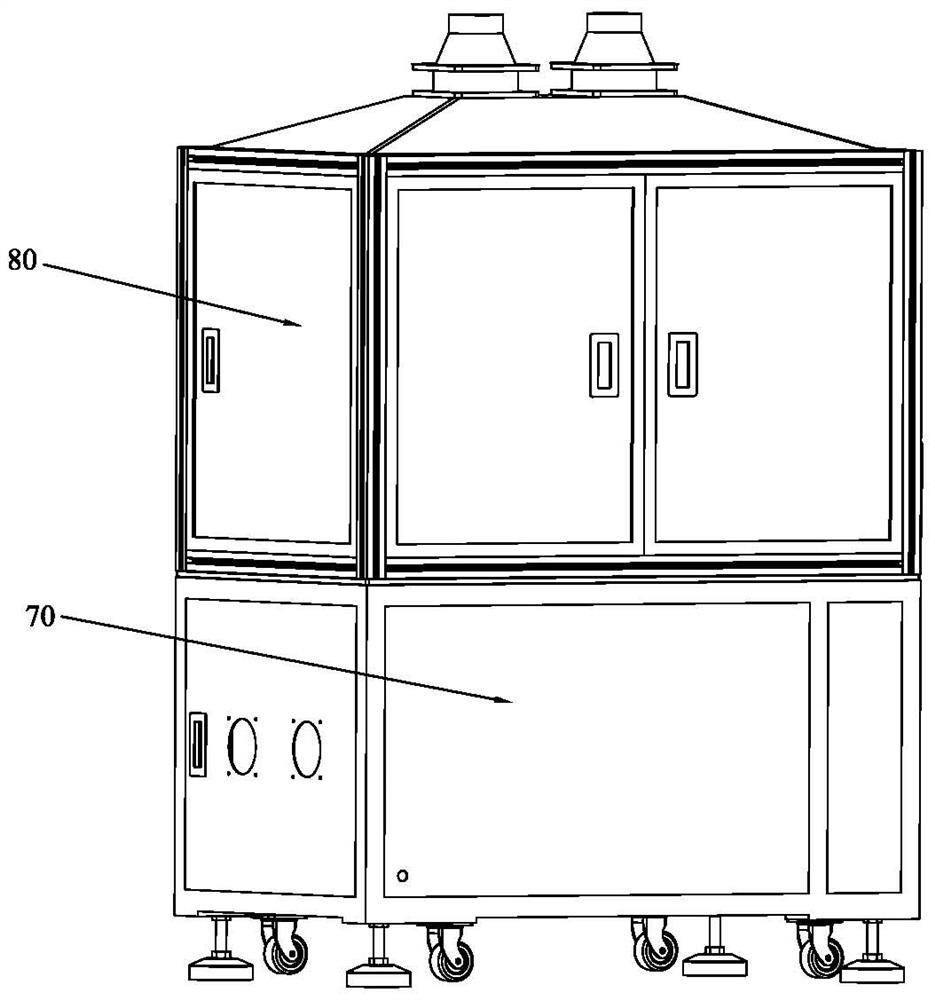

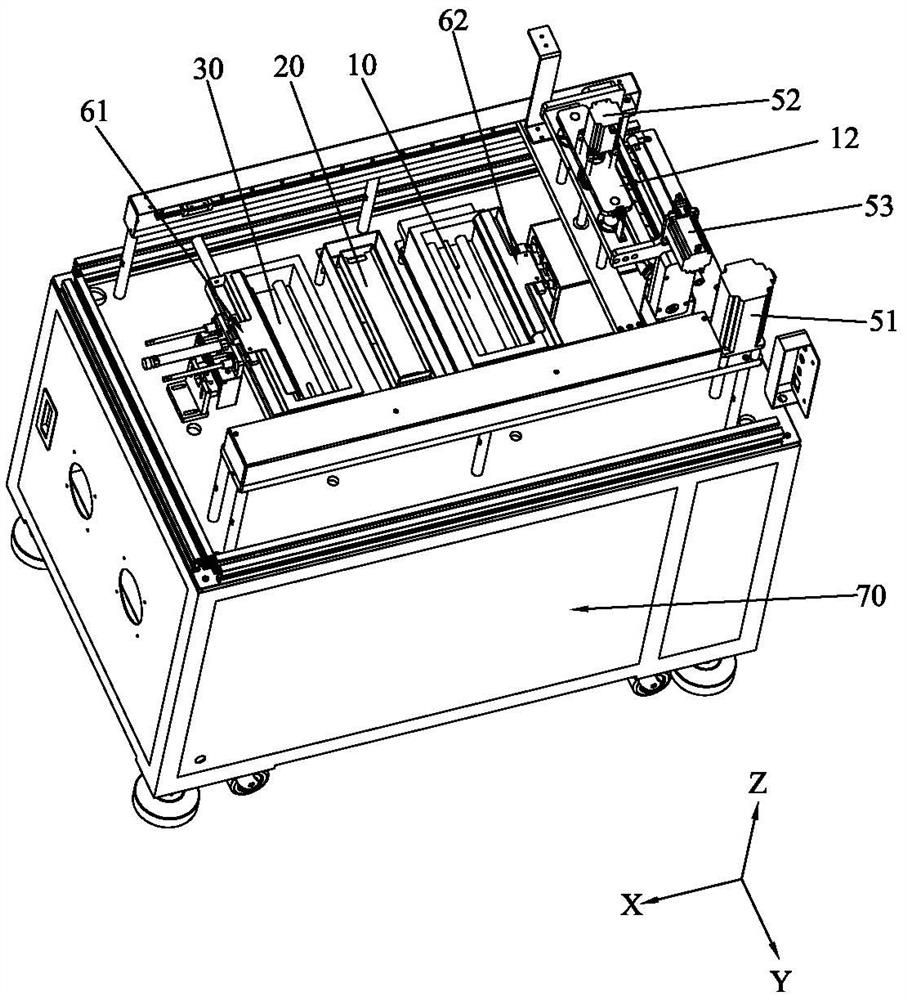

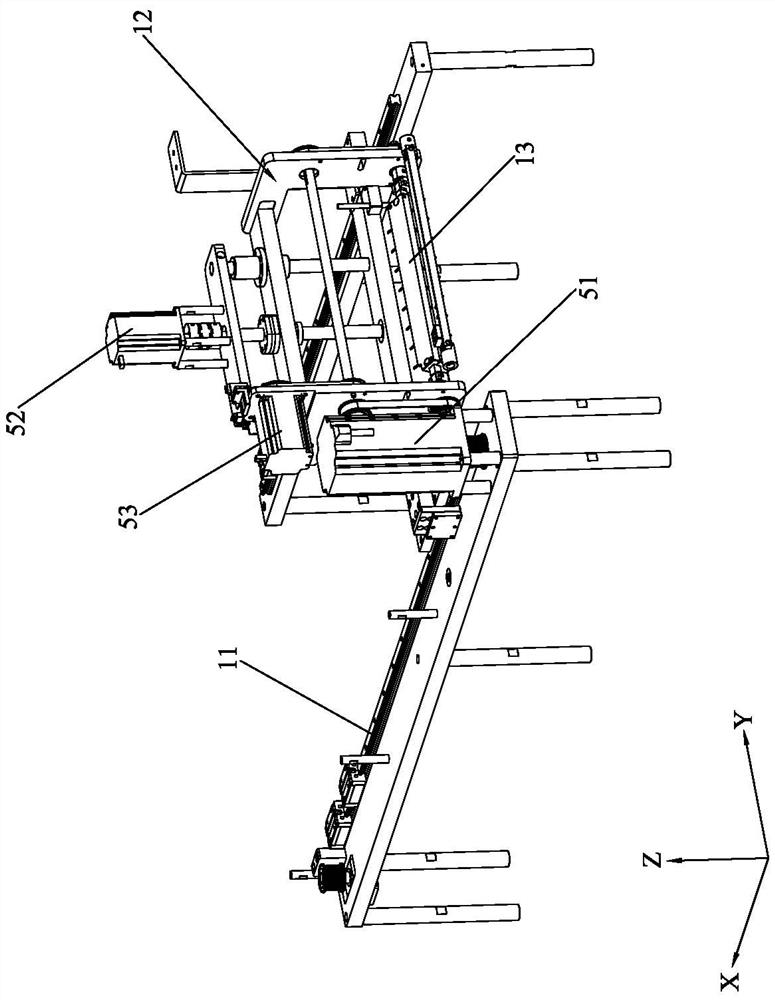

[0050] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the embodiment of the present invention.

[0051] An automatic soldering equipment that can protect the PIN pin of a transformer, including a jig transfer system, a high-temperature soldering system, a low-temperature soldering system, and a fluxing system;

[0052] The jig transfer system has a loading jig and a driving device that drives the loading jig to move; the high-temperature soldering system has a high-temperature soldering furnace 30; the low-temperature soldering system has a low-temperature soldering furnace 10; Furnace 20; the high-temperature solder furnace 30, low-temperature solder furnace 10, and flux furnace 20 are arranged in the X-axis direction of the loading jig; the drive device can selectively drive the loading jig to the flux furnace 20, low-temperature solder Furnace 10, high-temperature soldering furnace 30. When performing soldering operations, on the same m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com