Stacker crane

A palletizer and palletizing technology, applied in the field of automatic palletizing of bagged fluid materials, can solve problems such as affecting the physical and mental health of workers, high labor intensity, polluting the working environment, etc., to achieve automatic operation and beautiful stacking shape. neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

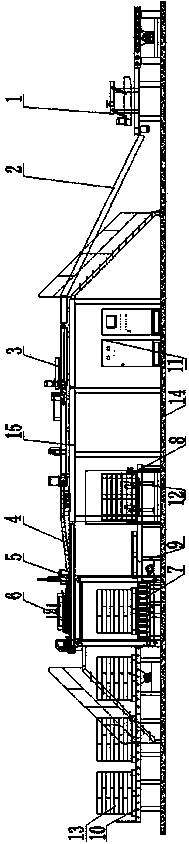

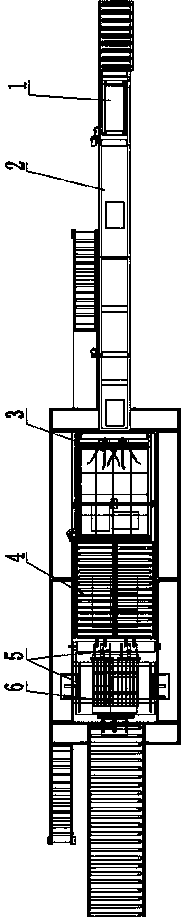

[0039] like figure 1 and figure 2 As shown in the figure, a palletizer includes a bag guide mechanism 3 located on the upper platform 15, a layer arranging and grouping mechanism 4, a layered bag pushing mechanism 5 and a flattening and exhausting mechanism 6; Mechanism 1, pallet lifting mechanism 7, pallet warehouse 8, pallet output mechanism 9, pallet output mechanism 10 and full-line electrical control system 11; and climbing conveying mechanism 2.

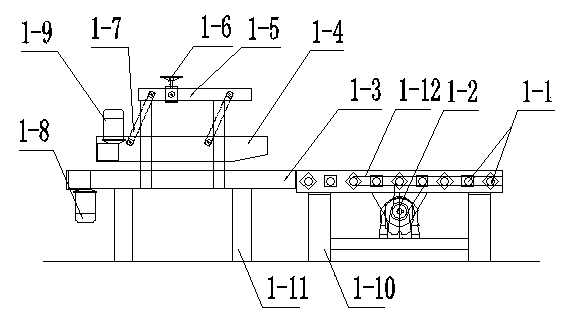

[0040] like image 3 and Figure 4As shown, the vibrating and compacting mechanism 1 includes a vibrating conveyor and a compacting conveyor close to the vibrating conveyor. The flat surface is installed on the first bracket 1-10. The conveying rollers 1-1 are connected by a chain 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com