Feeding device and feeding method

A direct-up, material-storing technology, applied in the field of feeding devices, can solve the problems of inability to save labor, large floor space, and small storage capacity, and achieve the effect of saving labor, reducing floor space, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

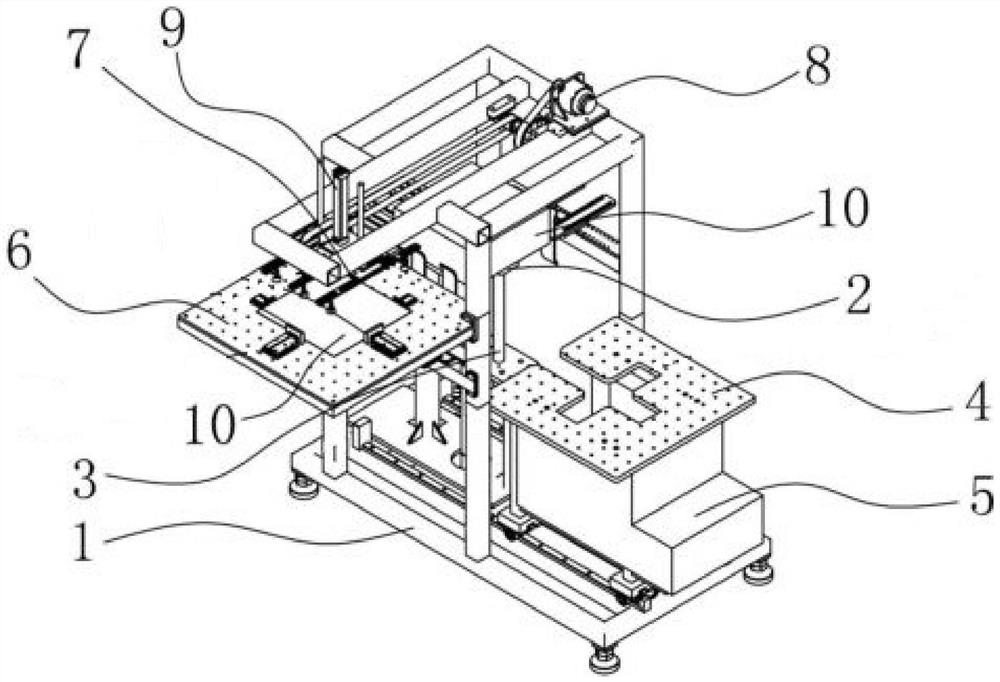

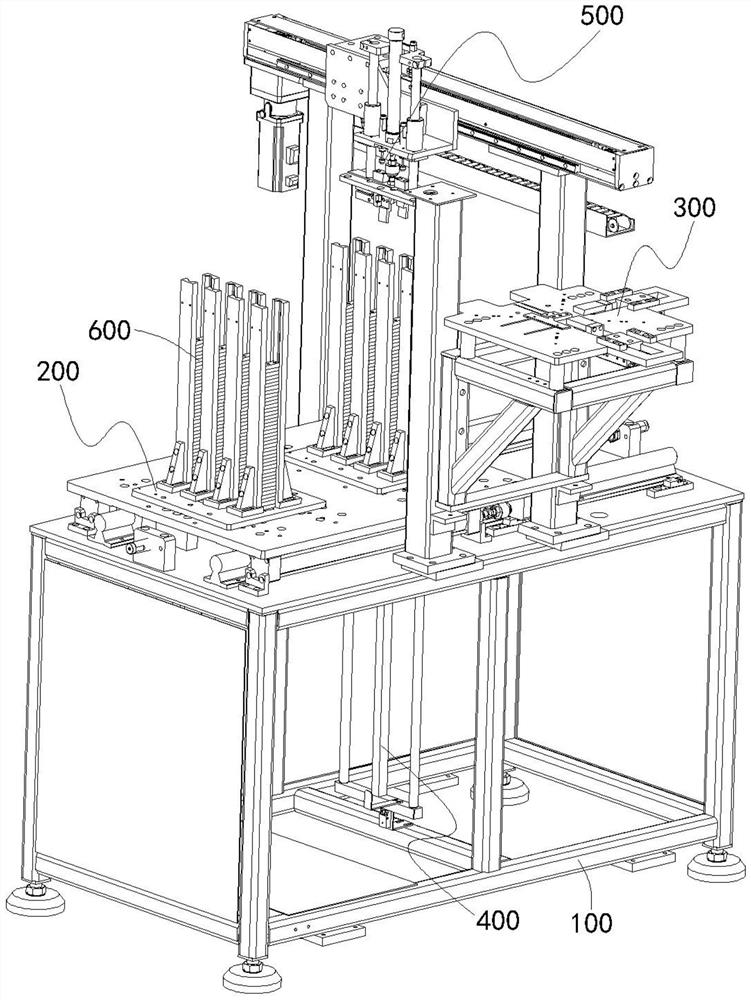

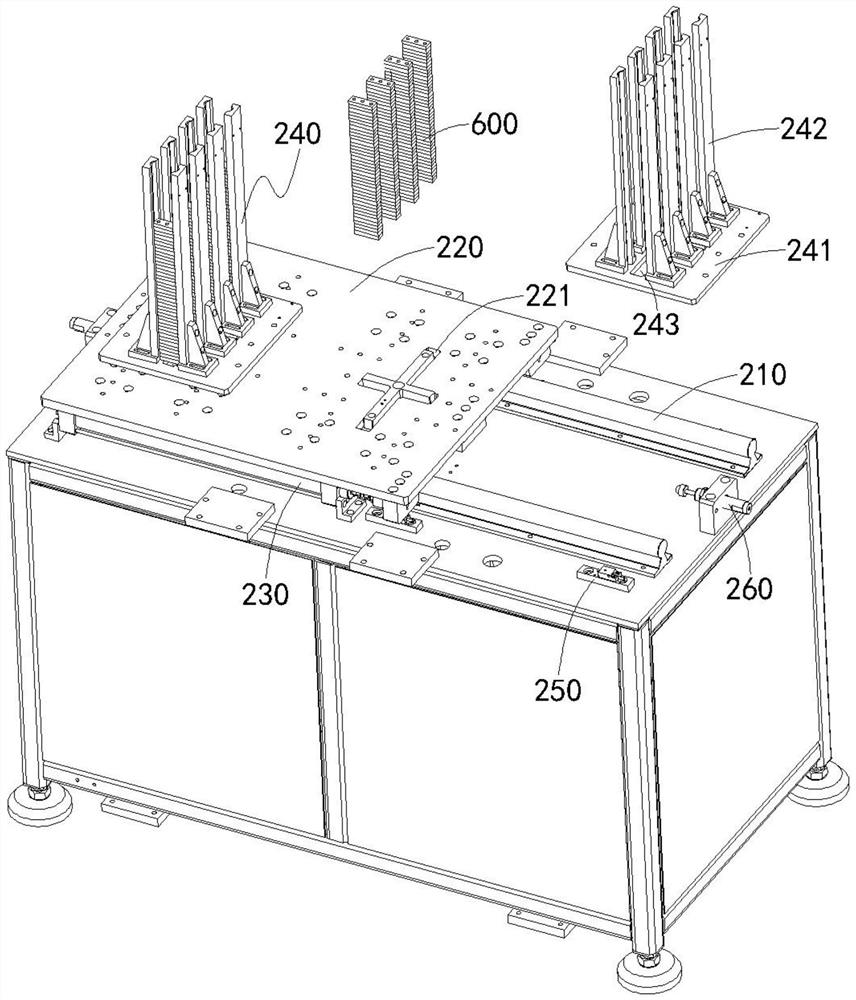

[0044] A feeding device, see figure 2 , which includes a rack 100 , a storage assembly 200 , a feeding assembly 300 , a feeding assembly 400 , and a retrieving assembly 500 . Wherein, the stocker assembly 200 is slidably installed on the top surface of the frame 100, and the stocker assembly 200 is used for placing the workpiece 600 to be loaded and having talcum powder stuck on the surface. The feeding assembly 300 is installed on the frame 100, and the feeding assembly 300 is positioned at one side of the material storage assembly 200, and one side of the storage assembly 200 is used for positioning the workpiece 600 from the storage assembly 200, to be picked up by the manipulator for post-processing. material. The feeding assembly 400 is installed on the frame 100 , the feeding assembly 400 is located directly below the storage assembly 200 , and the feeding assembly 400 lifts the workpiece 600 on the storage assembly 200 from bottom to top. The retrieving assembly 500 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com