Gantry Machine Tool for Fine Machining

A gantry machine tool and fine processing technology, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve problems such as the inability to meet people's processing speed, efficiency and precision requirements, to ensure good rate and processing efficiency. , to ensure a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

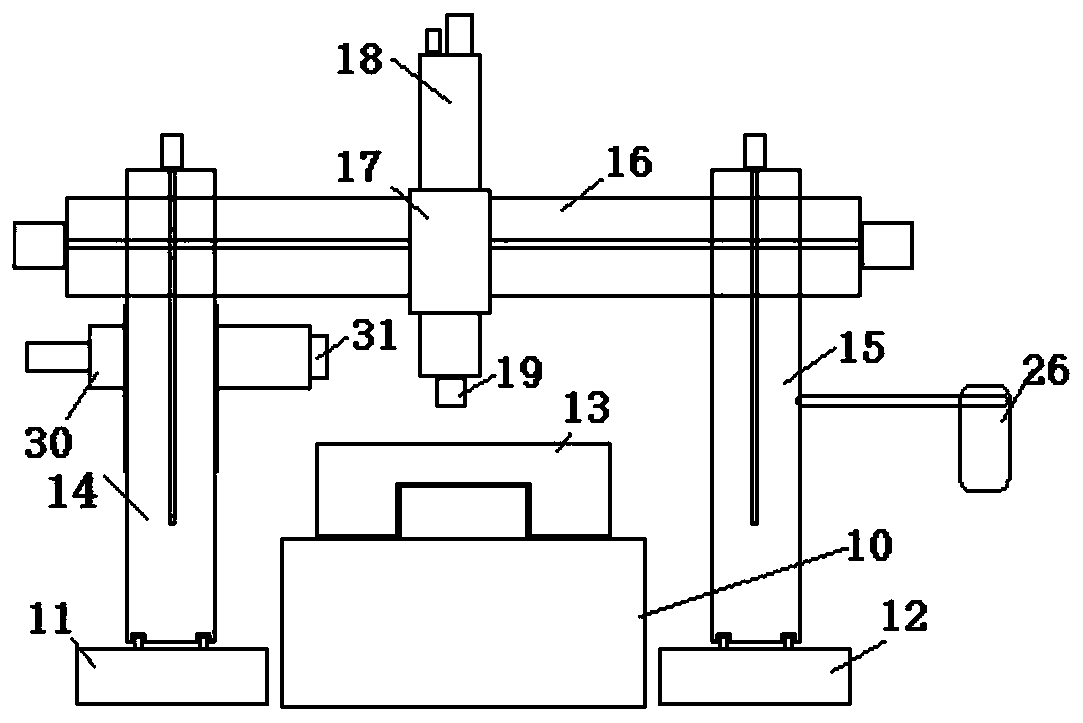

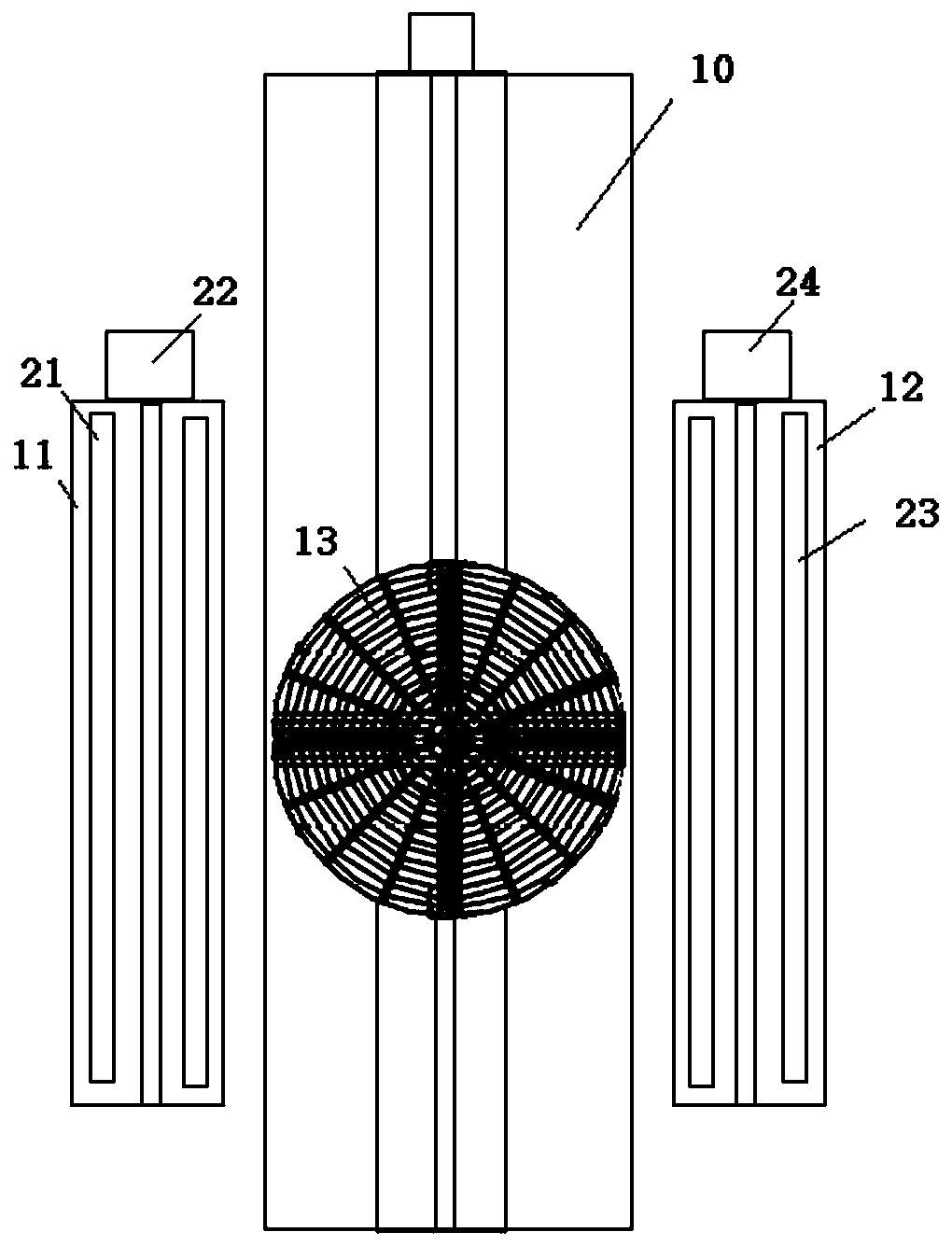

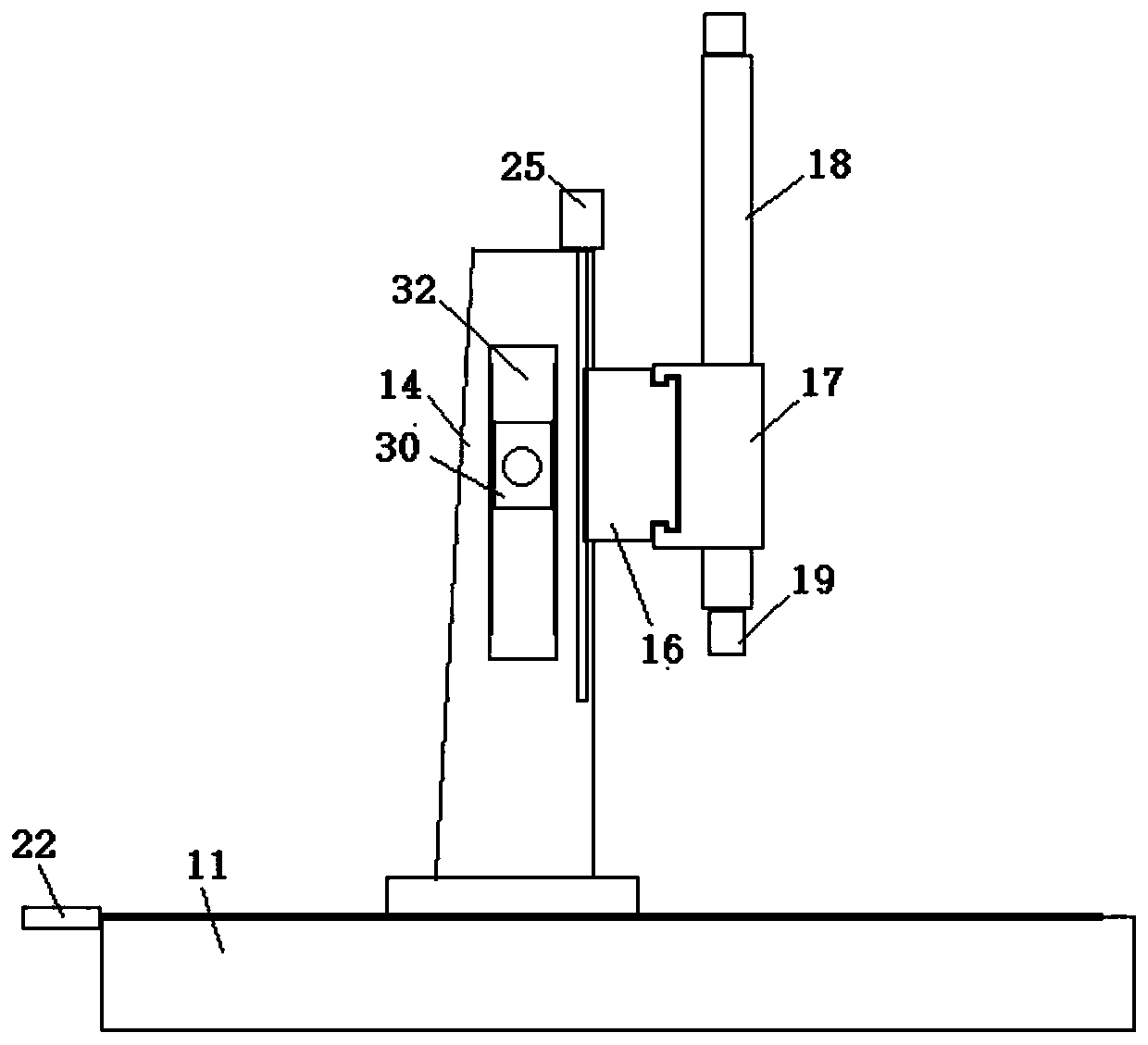

[0025] see Figure 1 to Figure 3 , shows one embodiment of the gantry machine tool for fine processing of the present invention.

[0026] In this embodiment, the gantry machine tool for fine processing includes a workpiece table 10, the two sides of the workpiece table 10 are respectively provided with a parallel left base 11 and a right base 12, and the top of the workpiece table 10 is provided with a rotating fixture 13.

[0027] Wherein, the left base 11 is provided with a left column 14 that can slide back and forth relative to each other, and the right base 12 is provided with a right column 15 that can slide back and forth relatively, and the left column 14 and the right column 15 can be carried out during sliding. synchronously, and the front side of described left column 14 and right column 15 is provided with the crossbeam 16 that can slide up and down relatively, and the front side of described crossbeam 16 is provided with the slide table 17 that can slide left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com