Panel processing technology

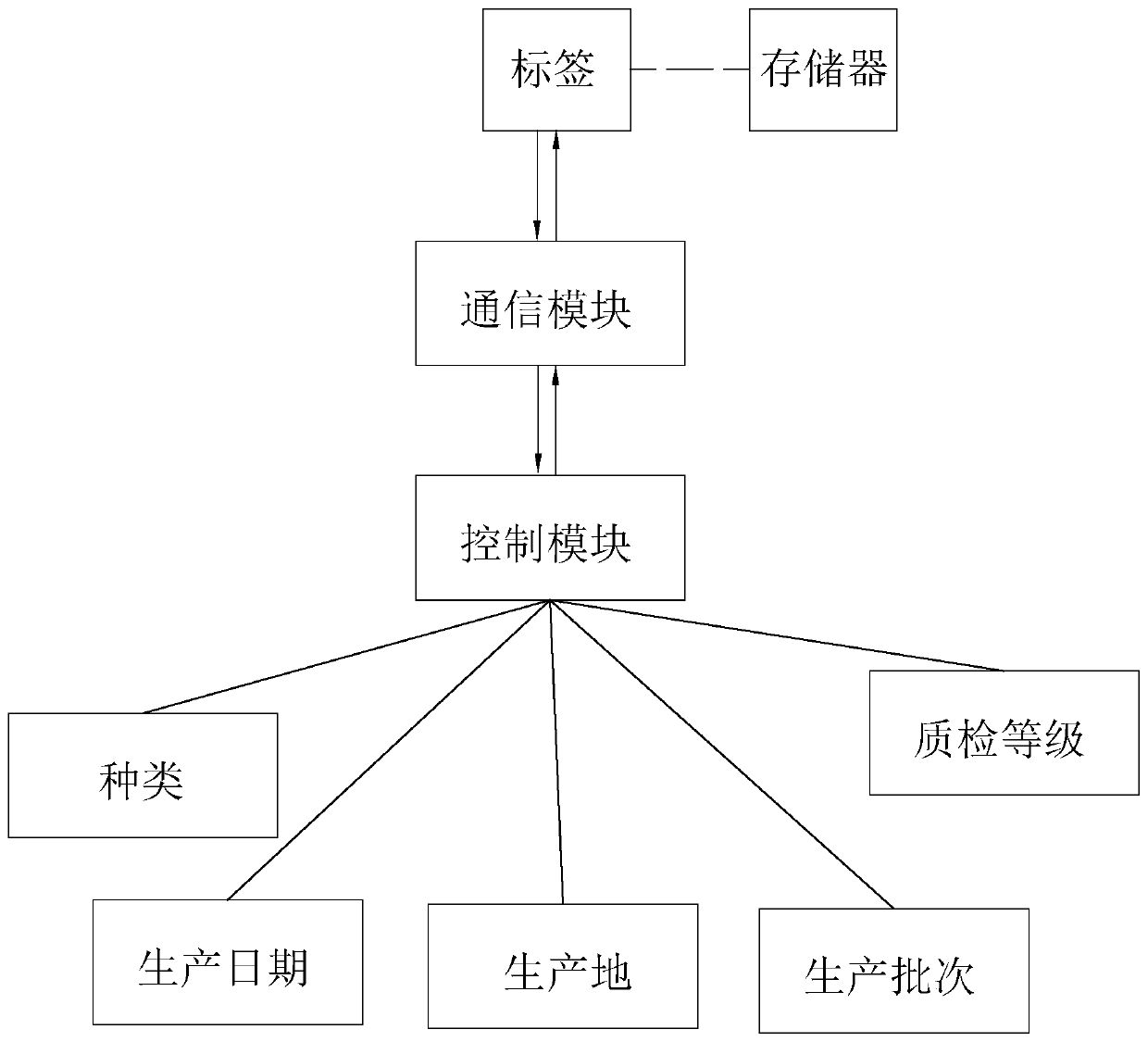

A board processing and board technology, applied in the direction of wood processing utensils, manufacturing tools, labels, etc., can solve the problems of prone to human error, no standards, inconvenient solid wood board supervision, etc., to reduce human errors, high accuracy, and management methods. The effect of facilitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

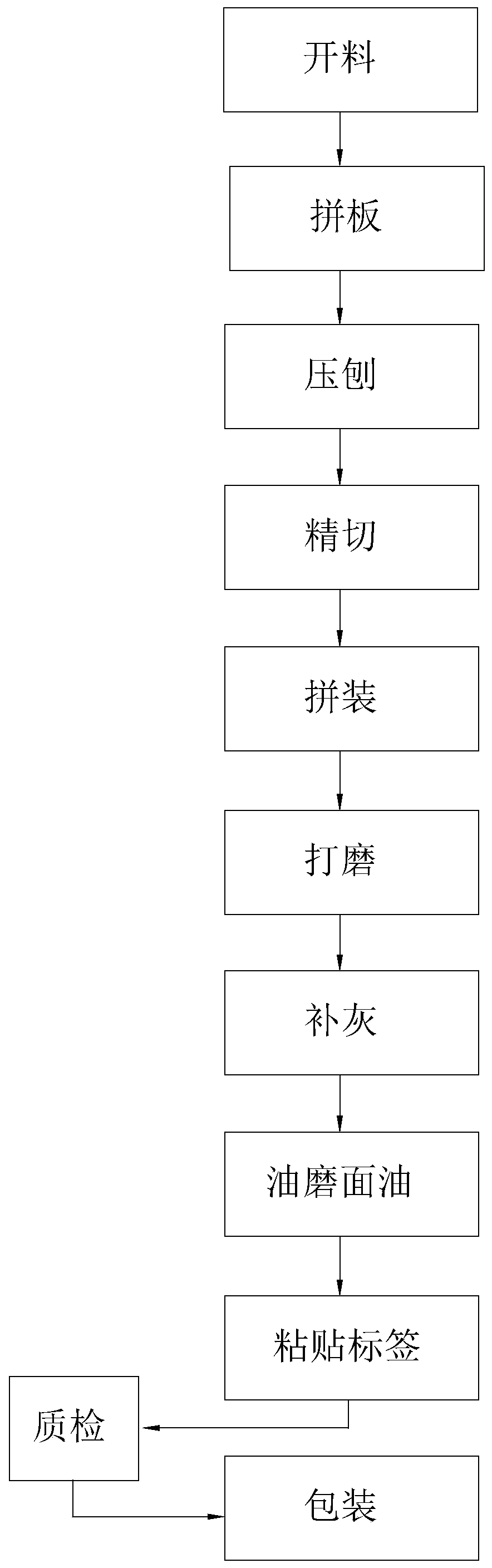

[0045] refer to figure 1 , is a kind of plate processing technique disclosed by the present invention, comprises the following steps:

[0046] Processing: Logs are cut into boards by sports car band saws, main force small band saws, etc.

[0047] Drying: Dry out the moisture and oil in the board by fumigation.

[0048] Cutting: According to the characteristics of size, knots, discoloration, decay, insect damage, cracking, and sharpening, the boards are screened, and the boards are cut according to preset specifications to form standard wooden strips.

[0049] Among them, the knots, that is, the branches in the trunk or the main branch wood, are divided into living knots or dead knots according to the degree of connection between the knots and the surrounding wood, and the knots destroy the uniformity and integrity of the board.

[0050] Discoloration, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com