CO2 laser light path lens temperature detection and temperature differential overrun alarm system

An alarm system and laser technology, applied in thermometers, signal transmission systems, electrical signal transmission systems, etc., can solve the problems of laser output power and stability reduction, lens burnout, etc., and achieve simple software development, long data transmission distance, and high sensitivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

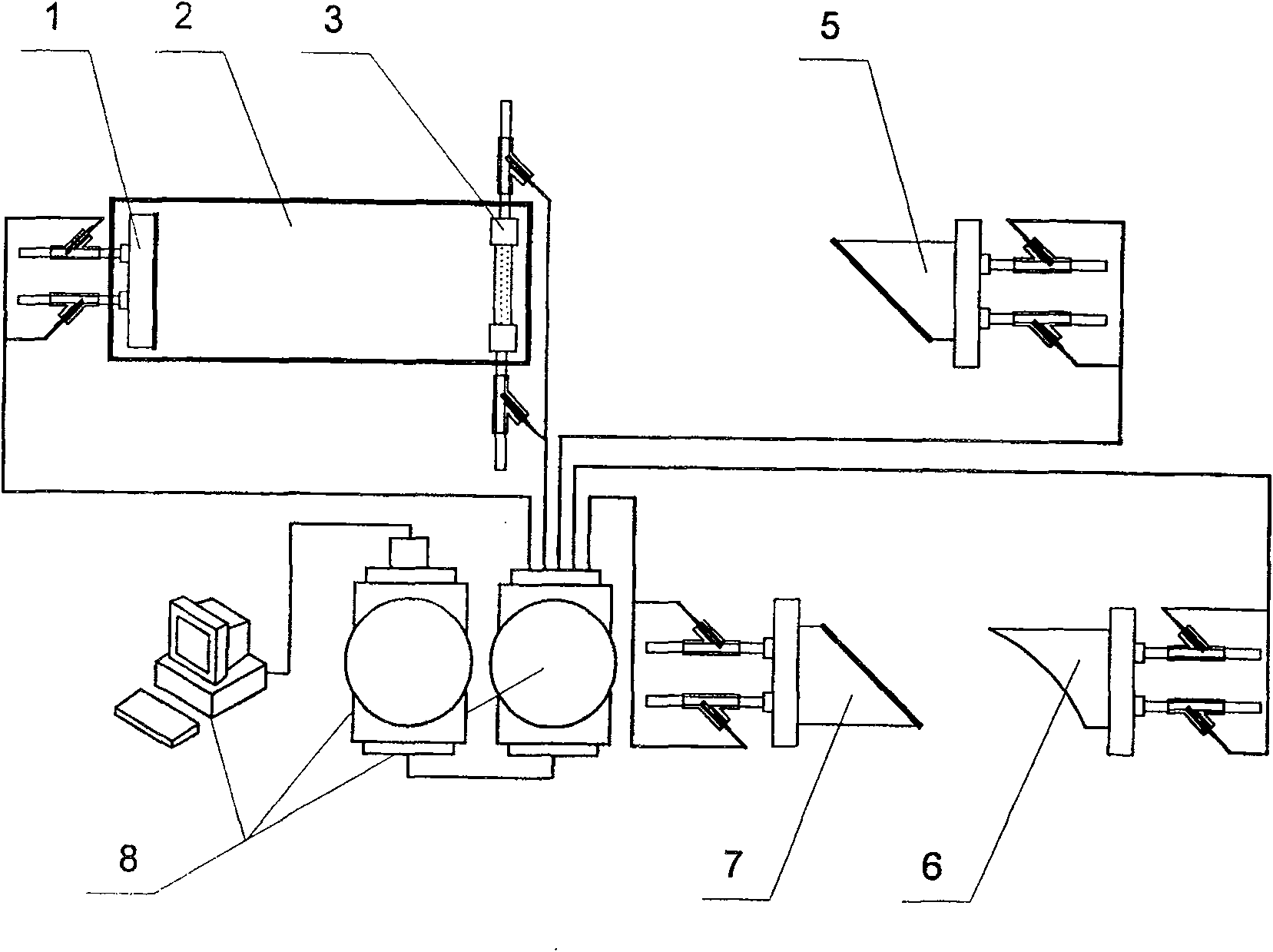

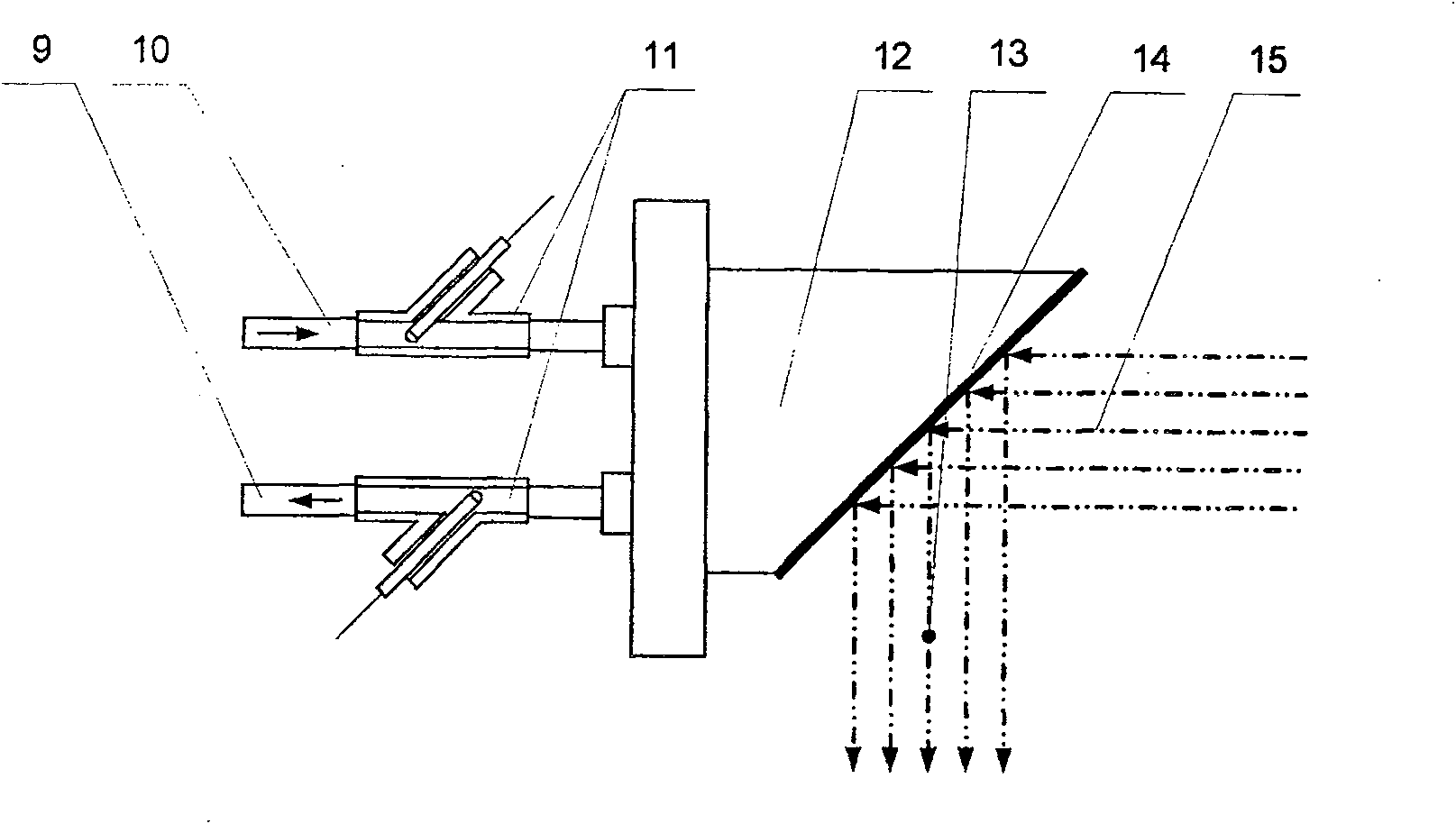

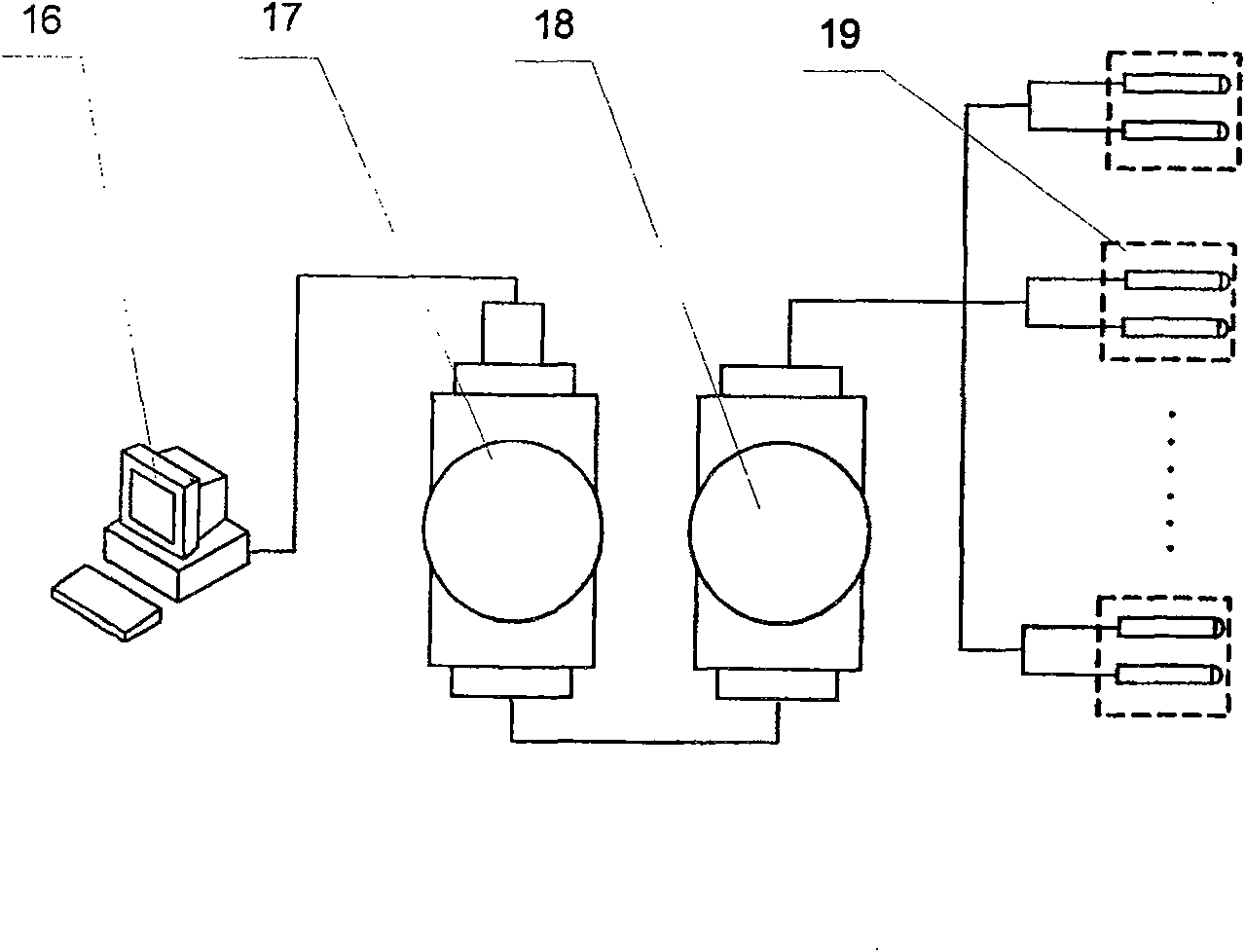

Method used

Image

Examples

Embodiment

[0043] (1) Calibration of the temperature difference interval;

[0044] The purpose of calibrating the temperature difference interval is to determine the upper limit of the temperature difference between the input and output cooling water, that is, when the temperature difference exceeds a certain value, it will alarm. The calibration of the temperature difference interval is related to factors such as lens pollution tolerance, laser output power, cooling water flow rate, etc., and needs to be determined through experimental analysis.

[0045] (2) Lens pollution signal extraction, using thermocouples to extract lens pollution signals from the inlet / outlet of lens cooling water and the temperature difference changes collected;

[0046] As the lens is polluted, the absorption rate of laser light increases significantly, which causes the temperature of the lens assembly to rise, thereby increasing the temperature of the output cooling water. Let the input cooling water temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com