Digging and anchoring all-in-one machine dynamic modeling and simulation method

A technology of mechanical modeling and simulation methods, which is applied in design optimization/simulation, special data processing applications, instruments, etc., to achieve the effect of reducing the amount of calculation, small deviation between predicted results and actual use, and accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

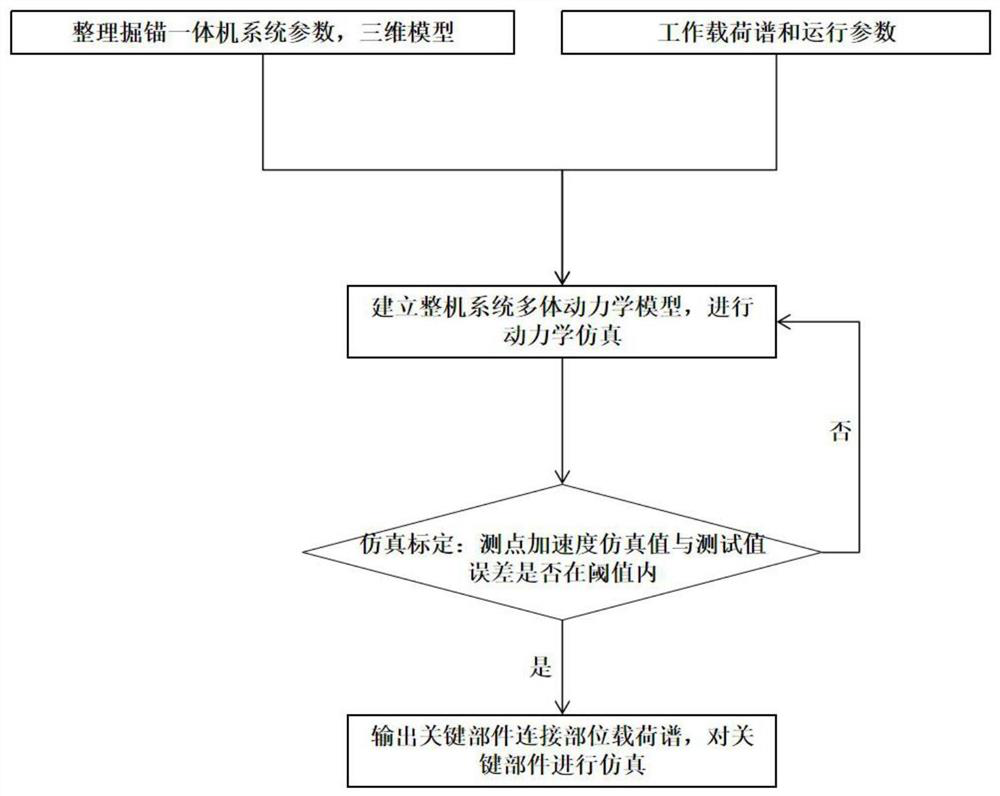

[0062] see Figure 1-7 , a dynamic modeling and simulation method of a bolter mining machine, comprising the following steps:

[0063] Step S1: Set a plurality of three-way acceleration measuring points on the bolter digging machine, and obtain the measured acceleration data of the measuring points; the number of measuring points in this embodiment is three, which are respectively set at the cutting boom, cutting Cutting reel racks and skids, such as Image 6 Measuring point 1, 2 and 3 are shown.

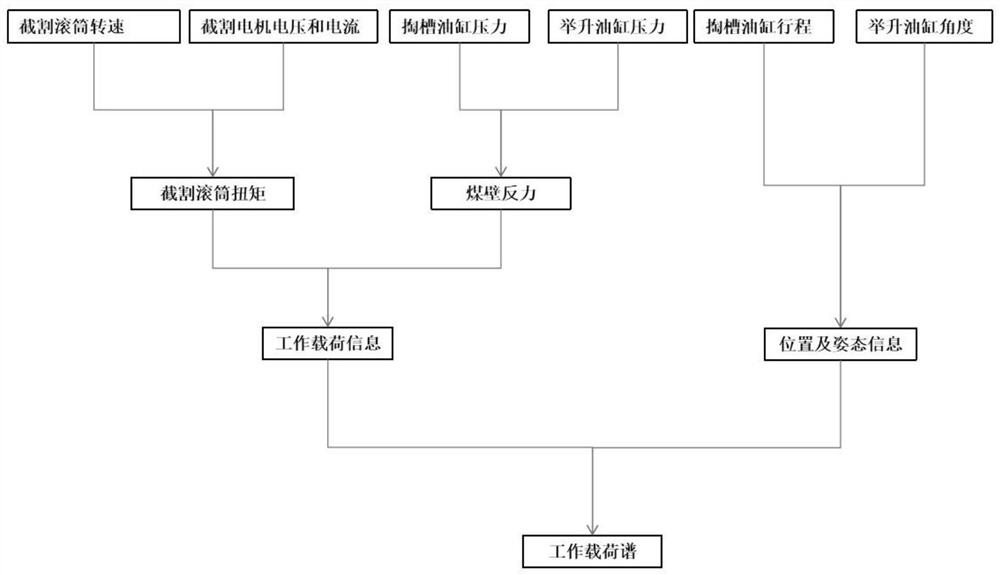

[0064] Step S2: Determine the load information of the cutting drum, and obtain the working load spectrum of the integrated bolter digging machine within one working cycle;

[0065] Step S3: Establish the multi-body dynamic model of the whole machine, combine the operating parameters and the working load spectrum as the excitation for dynamic simulation, and calibrate the measured acceleration data of the measuring point and the acceleration simulation data of the corresponding mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com