Manufacturing method of ultra-thin VC

An ultra-thin, ultrasonic technology, applied in the direction of manufacturing tools, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of scrapped raw materials, failure to use normally, low welding fastness, etc., to avoid waste and overcome spatter and oxidation, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

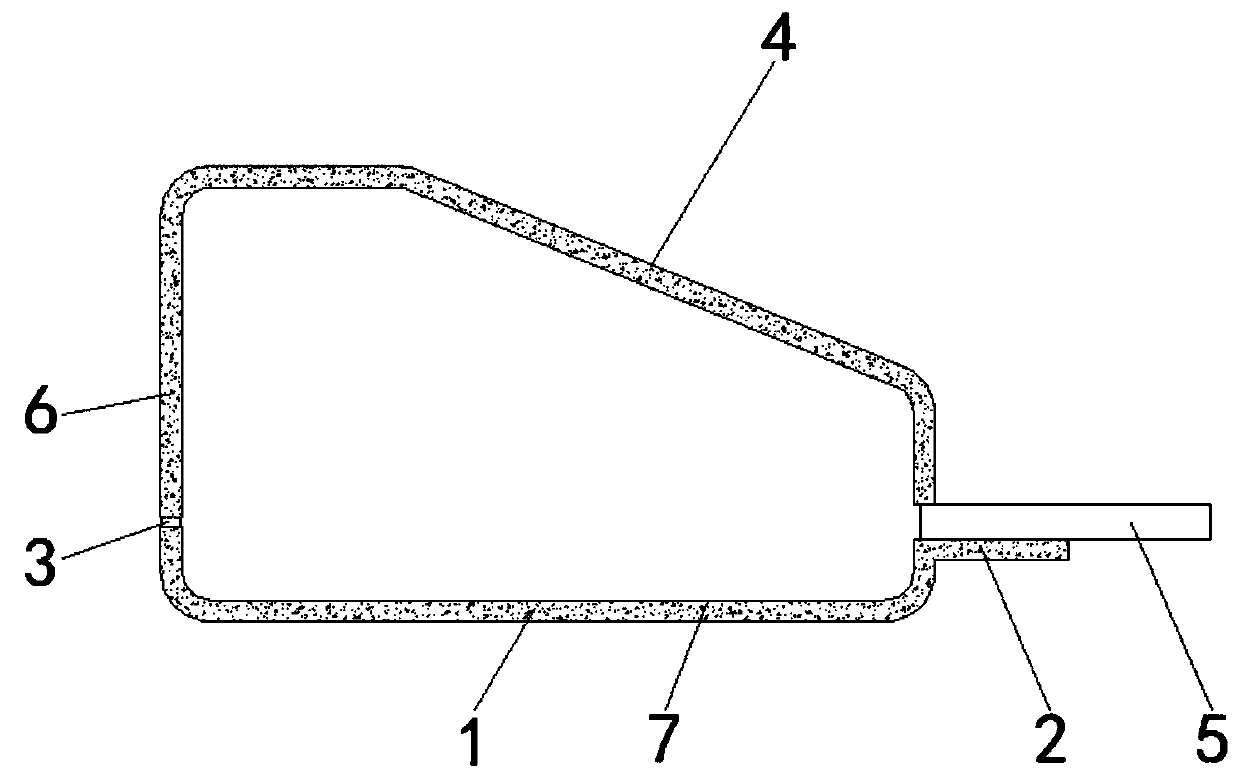

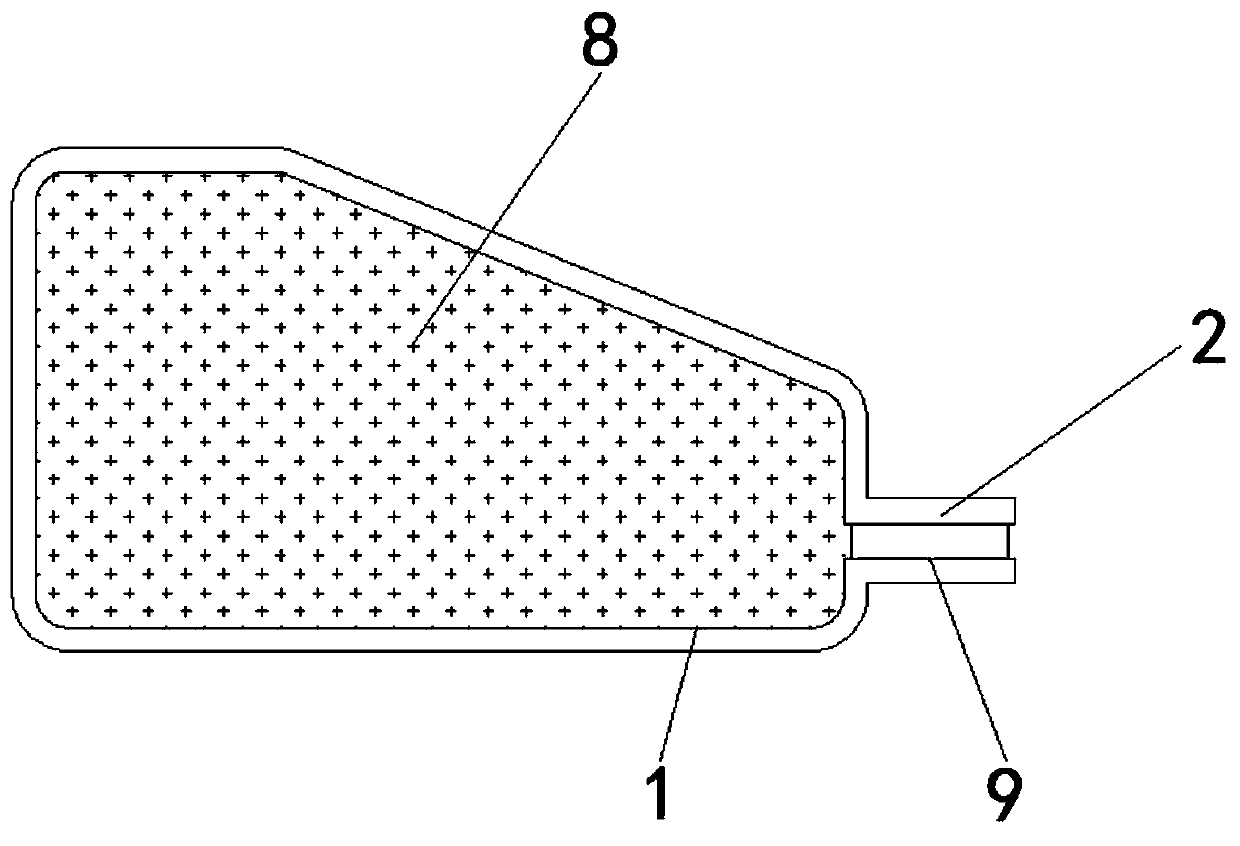

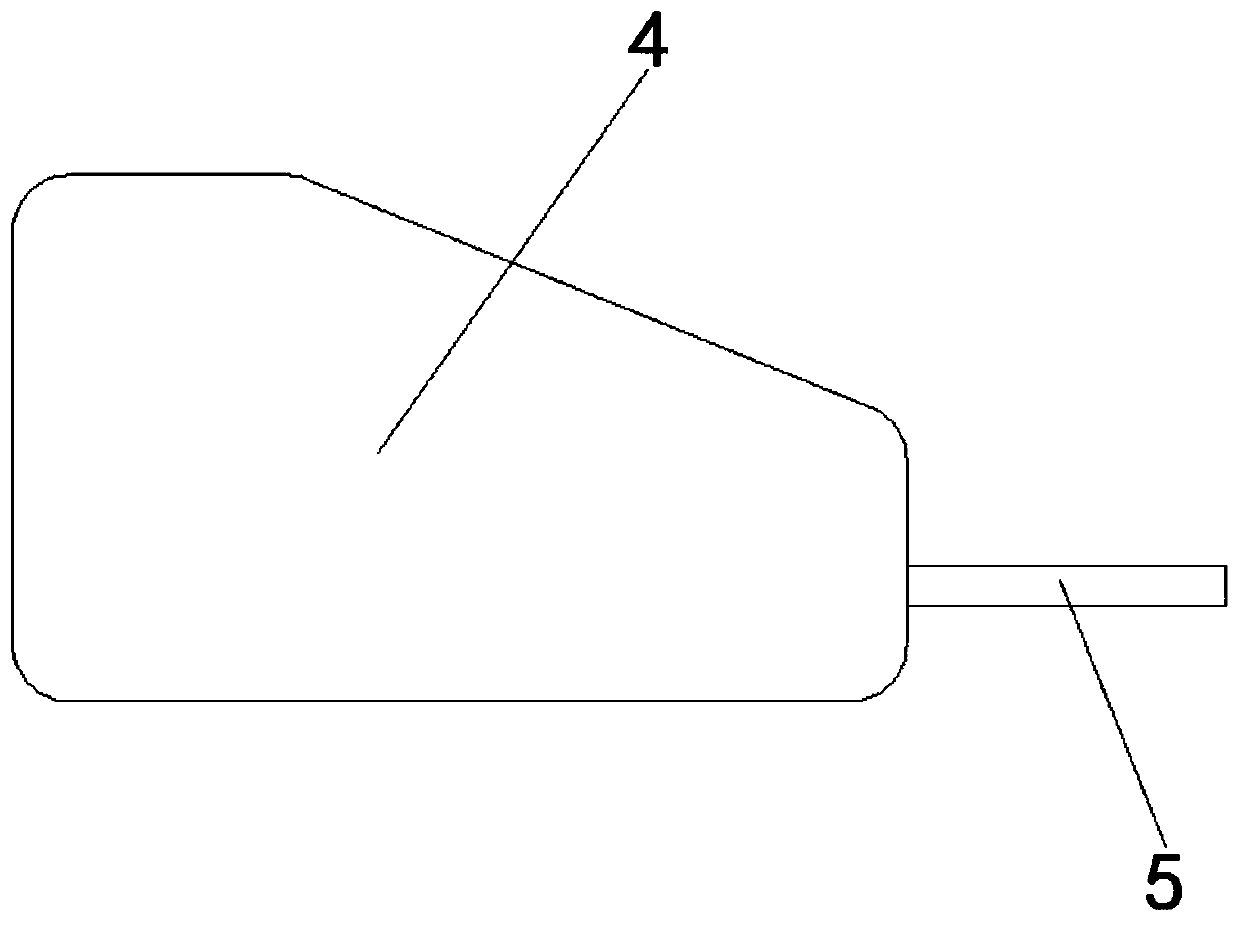

[0027] Embodiment 1: An ultra-thin VC, including a lower cover plate 1, a mounting plate 2 is fixedly installed on the right side of the lower cover plate 1, an upper cover plate 4 is fixedly installed on the top of the lower cover plate 1, and the lower cover plate 1 and The upper cover plates 4 are connected to each other to form an accommodating space, the lower cover plate 1 and the upper cover plate 4 have the same length, the left side of the connection between the lower cover plate 1 and the upper cover plate 4 is provided with a welding groove 3, and the upper cover plate 4 The liquid inlet pipe 5 is fixedly installed on the right side, and the wool layer 6 is fixedly installed inside the lower cover plate 1 and the upper cover plate 4. The capillary layer 6 is a copper mesh that is horizontally and vertically alternated, and the copper mesh is braided by multiple copper wires. Formed, the top of the lower cover plate 1 and the bottom of the upper cover plate 4 are prov...

Embodiment 2

[0034] Embodiment 2: An ultra-thin VC, including a lower cover plate 1, a mounting plate 2 is fixedly installed on the right side of the lower cover plate 1, an upper cover plate 4 is fixedly installed on the top of the lower cover plate 1, and the lower cover plate 1 and The upper cover plates 4 are connected to each other to form an accommodating space, the lower cover plate 1 and the upper cover plate 4 have the same length, the left side of the connection between the lower cover plate 1 and the upper cover plate 4 is provided with a welding groove 3, and the upper cover plate 4 The liquid inlet pipe 5 is fixedly installed on the right side, and the wool layer 6 is fixedly installed inside the lower cover plate 1 and the upper cover plate 4. The capillary layer 6 is a copper mesh that is horizontally and vertically alternated, and the copper mesh is braided by multiple copper wires. Formed, the top of the lower cover plate 1 and the bottom of the upper cover plate 4 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com