Semiconductor device and method of polishing and cleaning wafer

A semiconductor and wafer technology, applied in the field of equipment used in the chemical mechanical planarization process, to achieve the effect of improving reliability and smoothness, and ensuring good rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following specific examples and specific implementation methods have made a better interpretation of the gist of the present invention, and the combination of the accompanying drawings will help the public and those skilled in the art to deepen their understanding of the content of the patent of the present invention.

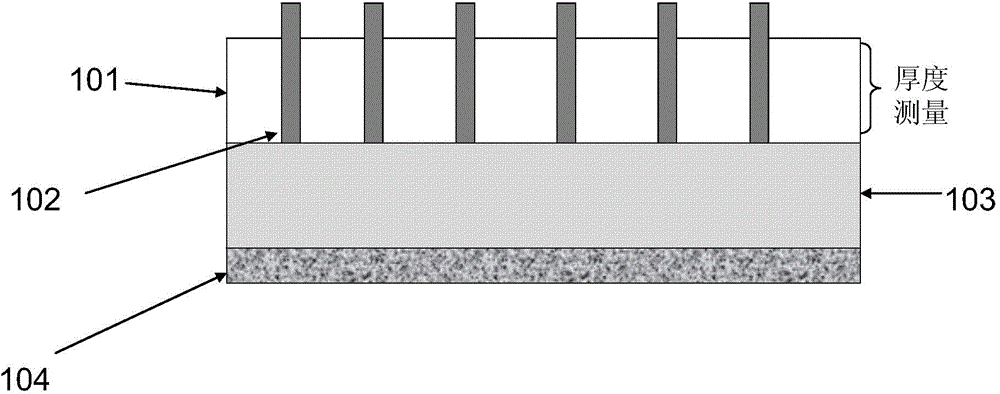

[0028] figure 1 The structure of the wafer to be planarized in the present invention is introduced. As we all know, the wafer used in the semiconductor industry is usually a circular sheet with a thickness of about 0.50 mm and a diameter of 8 inches or 12 inches. On the thickness of the wafer less than one millimeter, due to the difference in its material composition, it can still be divided into several layers artificially, so as to better understand the changes and effects of the processing technology on the wafer. In order to show the material composition and structure of each layer of the wafer more clearly, the drawings in the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com