Automatic wire pulling machine for transformer

A transformer and automatic technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of poor products, low production efficiency, high labor intensity, etc., to improve production efficiency, ensure good rate, and reduce labor. The effect of labor intensity and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

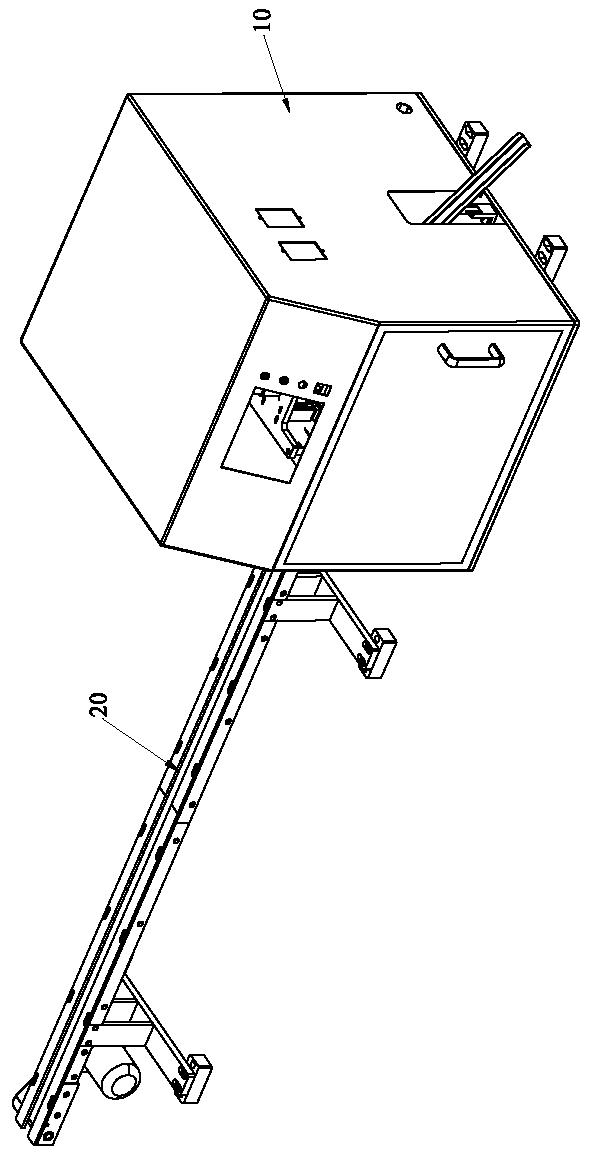

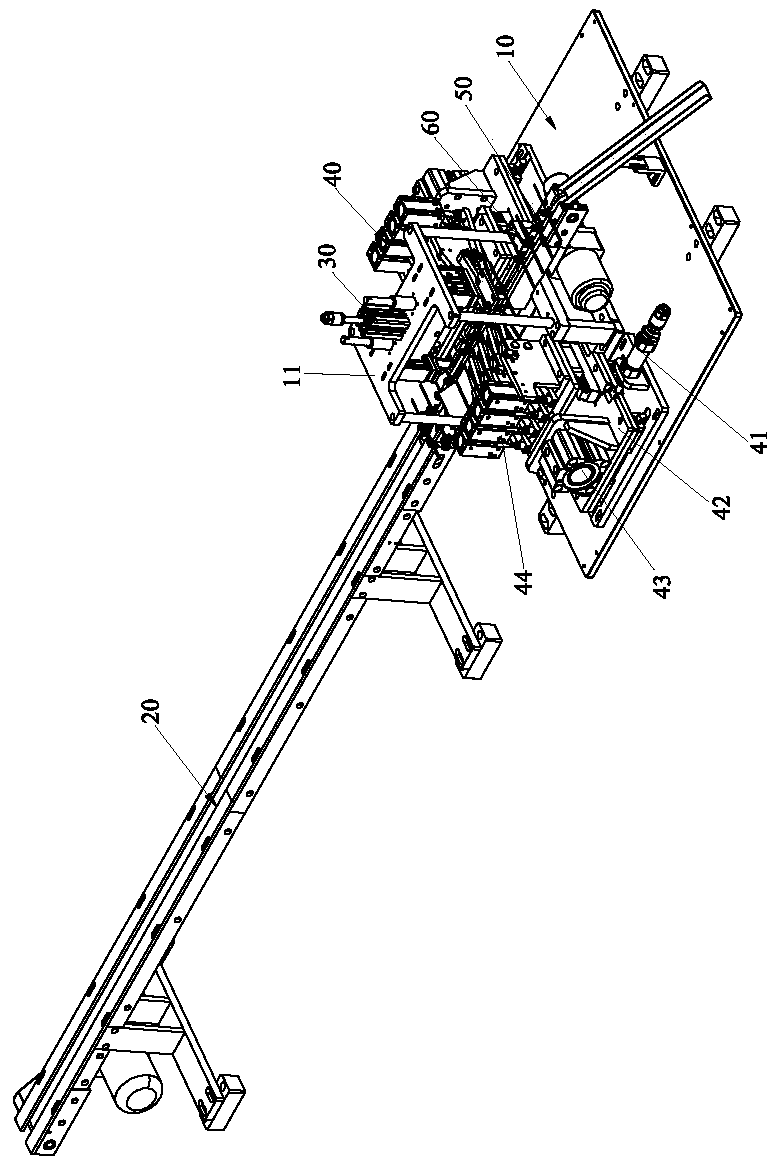

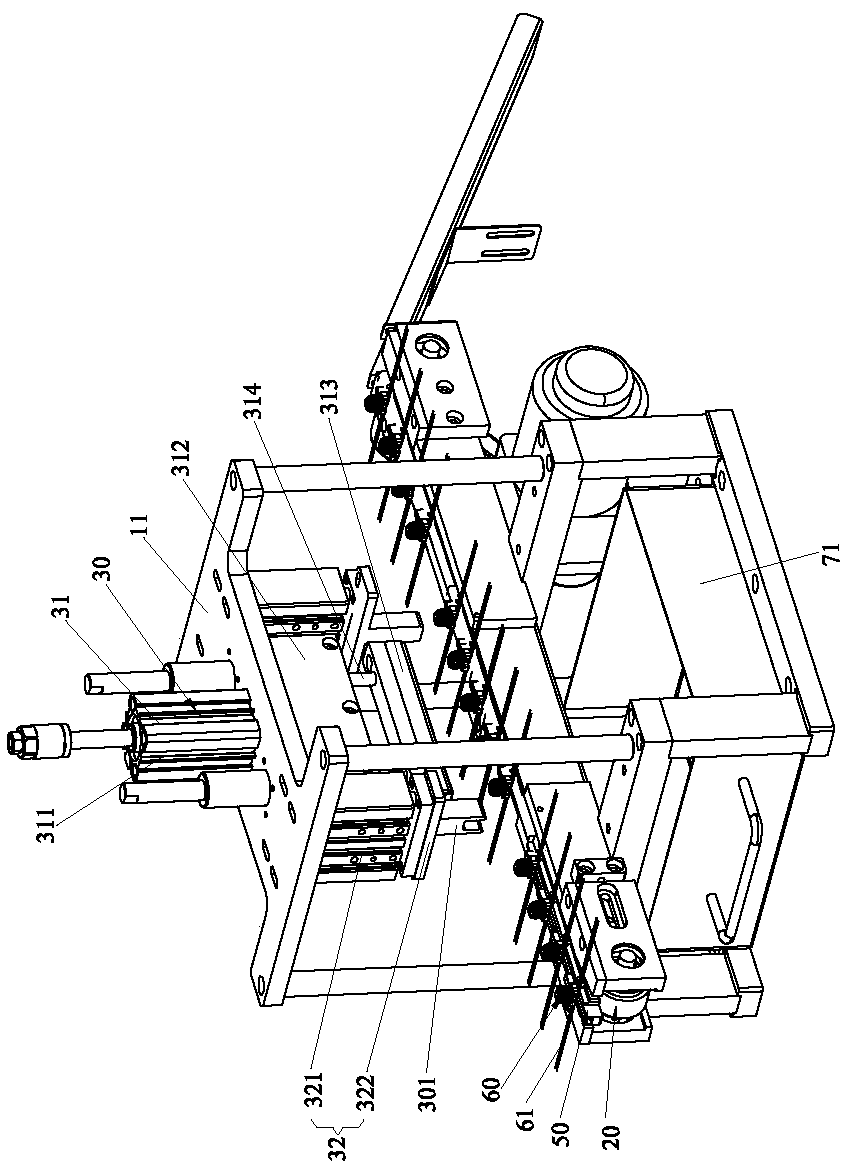

[0044] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10, a control mechanism (not shown in the figure), a conveying mechanism 20, a jig fixing mechanism 30, a wire pulling mechanism 40 and a transformer control mechanism. Tool 50.

[0045] The control mechanism is arranged on the frame 10 . The conveying mechanism 20 is arranged on the frame 10 and is electrically connected with the control mechanism. In this embodiment, the conveying mechanism 20 is a structure in which a motor drives a belt to rotate. The conveying mechanism 20 is provided with a photoelectric sensor switch (not shown in the figure) for sensing the position of the transformer jig.

[0046] The jig fixing mechanism 30 is arranged on the frame 10 and directly above the conveying mechanism 20 , and the jig fixing mechanism 30 is electrically connected with the control mechanism. The jig fixing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com