Special-shaped rivet-free riveting structure and forming device and method

A technology of rivetless riveting and forming device, applied in the field of forming device and special-shaped rivetless riveting structure, can solve the problems of reducing riveting processing efficiency, distance process limitation, etc., and achieves high production efficiency, widening process range and high connection strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

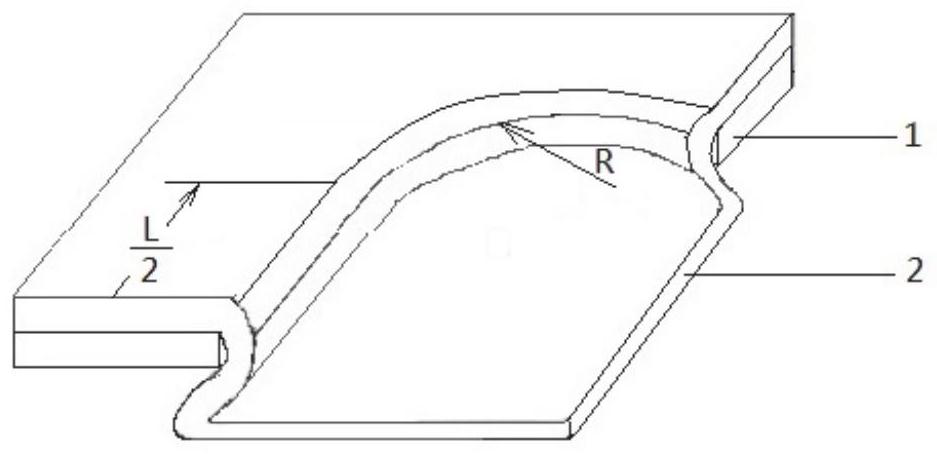

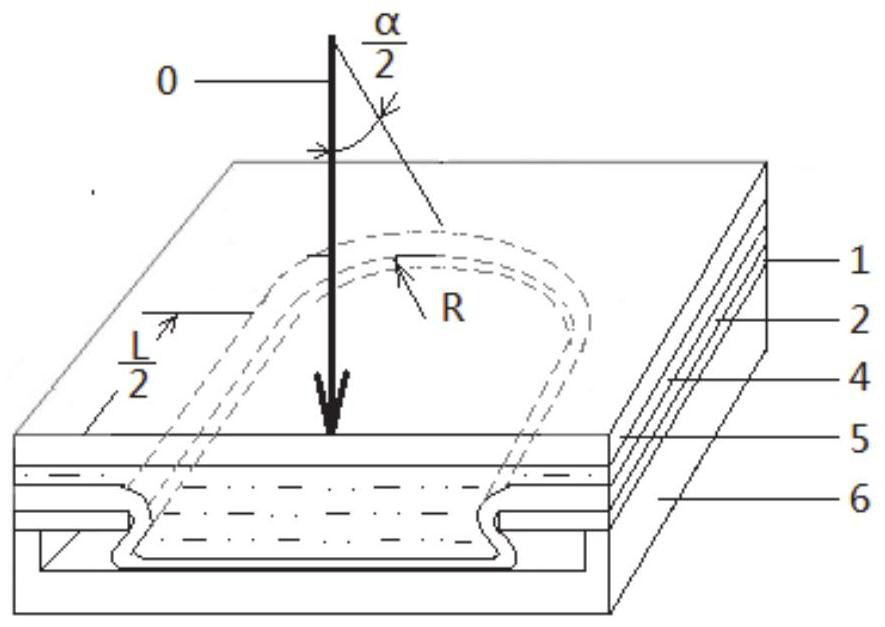

[0059] In a typical implementation of the present invention, 1 / 4 of its structure is as figure 1 As shown, a special-shaped rivetless riveting structure includes a riveted first plate and at least one layer of second plate, the first plate has a special-shaped hole, the second plate is provided with a recess, and the non-recessed part of the second plate is overlapped with the first plate above, the recess protrudes from the shaped hole of the first plate, and the depth of the recess is greater than the sum of the thicknesses of the first plate and the second plate.

[0060] In this implementation, a layer of the second plate is taken as an example for description.

[0061] Wherein, the concave portion includes a bottom surface, and a side wall is provided on the circumferential side of the bottom surface, and the concave portion is formed by the bottom surface and the side wall. The centrally protruding arc shape makes the recess form an undercut structure with a small mouth...

Embodiment 2

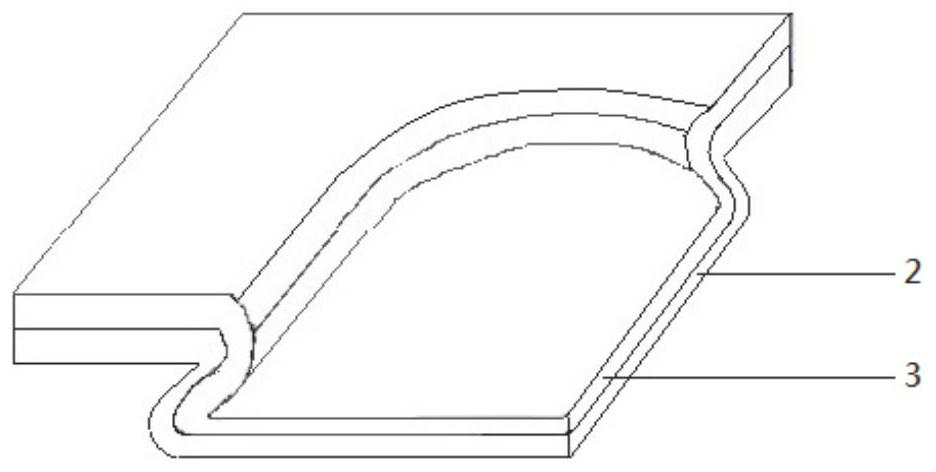

[0079] A special-shaped rivetless riveting structure, 1 / 4 of which is as figure 2 As shown, there are at least two layers of riveted plates, and the multi-layer plates are riveted through recesses, and the shape of the recesses is a special shape.

[0080] In this embodiment, the concave portion is in the shape of a key, and the two ends of the concave portion are arc-shaped, which can be a semicircle with a radius of R, the two sides of the concave portion are straight lines, the length of the straight line of the concave portion is L, and the total length of the concave portion is L. +2R, and the length L / width 2R>1 of the straight line.

[0081] Specifically, the recess includes a bottom surface, a side wall is provided on the circumferential side of the bottom surface, and the recess is formed by the bottom surface and the side wall, and the side wall of the recess is an arc shape protruding toward the center of the bottom surface, so that the recess forms an undercut str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com