Rivet and vehicle with same

A technology of rivets and nail rods, which is applied in the direction of rivets, screws, threaded fasteners, etc., which can solve the problems of large bending angle, low load-bearing strength, and easy bending and movement of the lower sheet metal, so as to reduce the quantity and lighten the vehicle. Weight, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

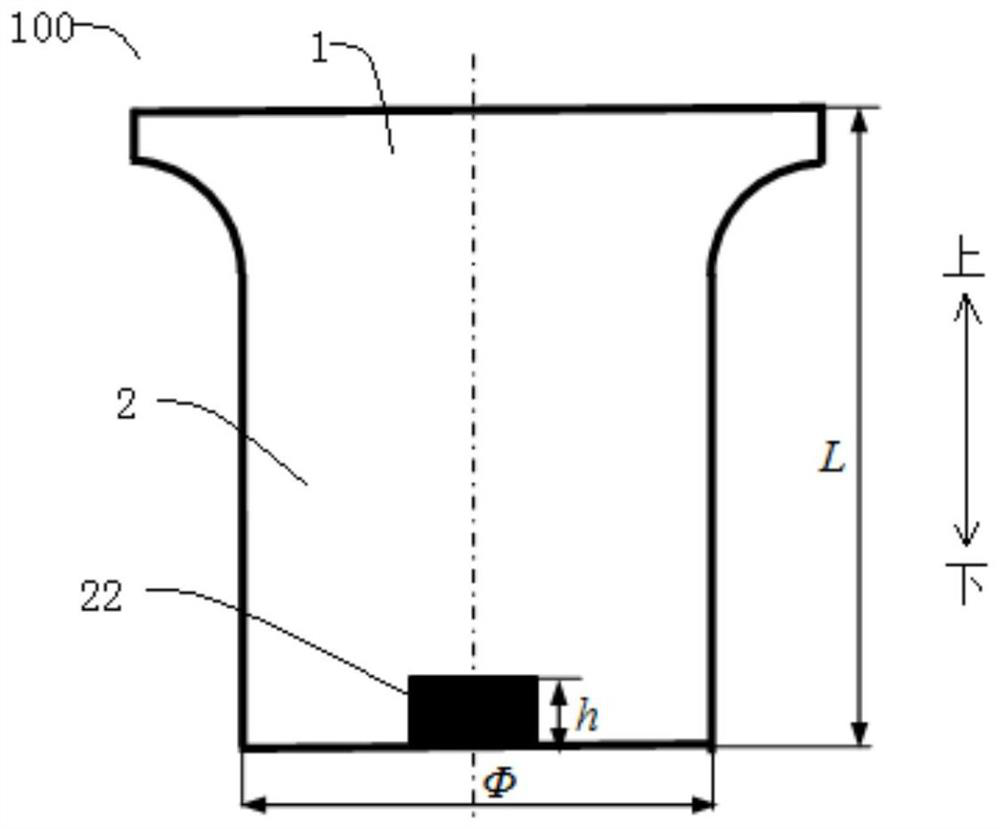

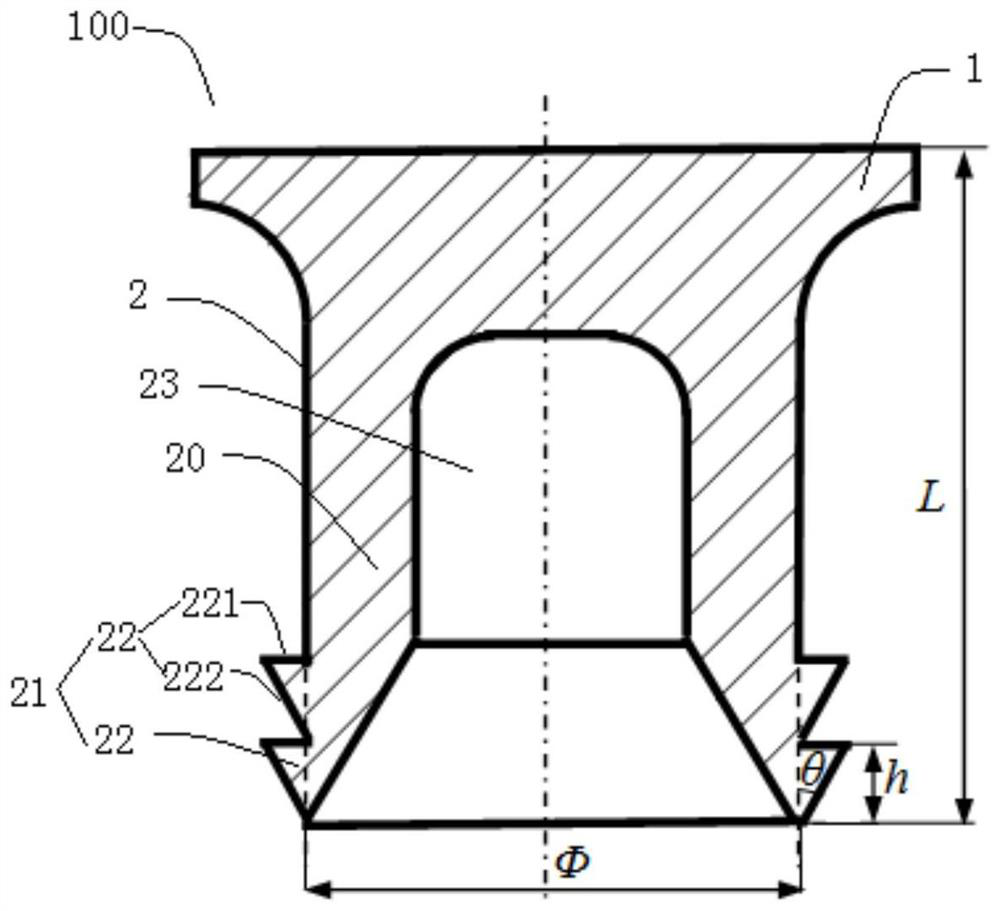

[0048] The rivet 100 in this embodiment is a semi-hollow self-piercing rivet 100 , and the rivet 100 includes: a nail head 1 and a nail shank 2 .

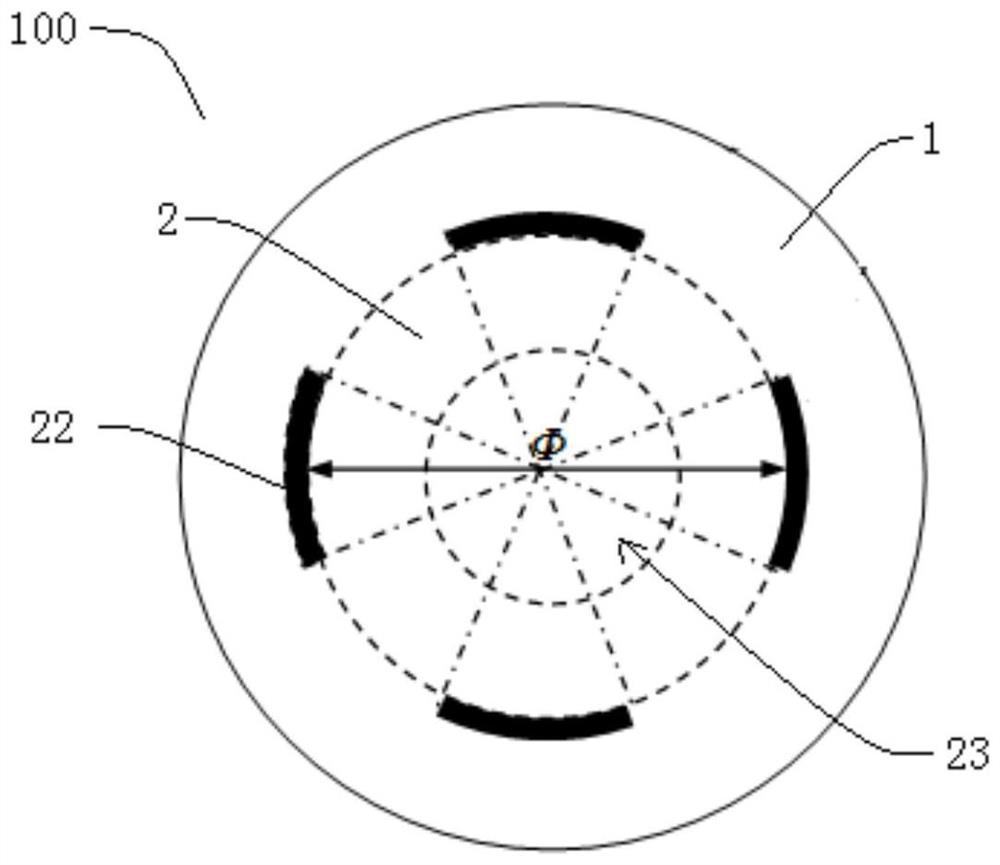

[0049] Wherein, the nail head 1 is formed in a circular shape, and the nail shaft 2 is also formed in a cylindrical shape. At least part of the nail shank 2 along the length direction is formed as an expansion deformation part 20, and a deformation cavity 23 is defined in the expansion deformation part 20. direction and gradually decreases in the direction away from the nail head 1. A plurality of reinforcing teeth 22 are formed on the outer peripheral wall of the expansion deformation part 20, and the plurality of reinforcing teeth 22 are divided into 2 tooth groups, and the 2 tooth groups are arranged at intervals along the axial direction of the nail rod 2, and each tooth group includes 3 teeth along the The reinforcement teeth 22 arranged at uniform intervals in the circumferential direction of the nail shank 2 are formed as t...

Embodiment 2

[0054] The general structure and forming process of the rivet 100 of this embodiment are the same as those of the rivet 100 in the first embodiment, the difference is that the number N of reinforcing teeth 22 in each tooth group is 4, and 4 reinforcing teeth 22 They are evenly spaced along the axial direction of the nail rod 2 .

Embodiment 3

[0056] The general structure and forming process of the rivet 100 of this embodiment are the same as those of the rivet 100 in the second embodiment, the difference is that the sum of the radians of all reinforcing teeth 22 in each tooth group corresponds to the circumference of the shank 2 The ratio a of radians is 3 / 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com