Electromagnetic riveting device for large-size thin-walled workpiece and riveting method

An electromagnetic riveting technology for thin-walled workpieces, which is applied in the field of electromagnetic riveting devices for large-scale thin-walled workpieces, can solve the problems of large recoil, low efficiency, and high processing costs, and achieve reduced volume and weight, reduced manufacturing costs, and reduced impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

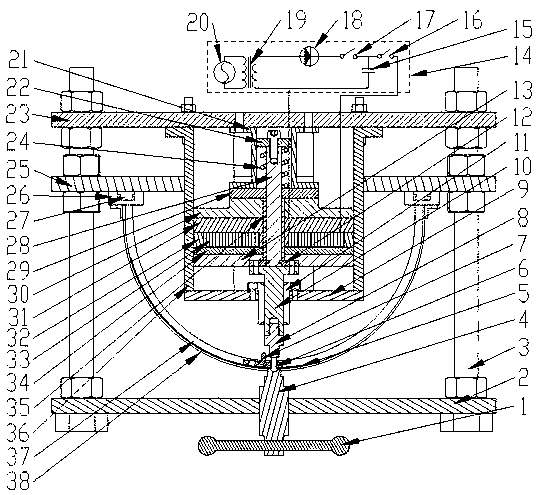

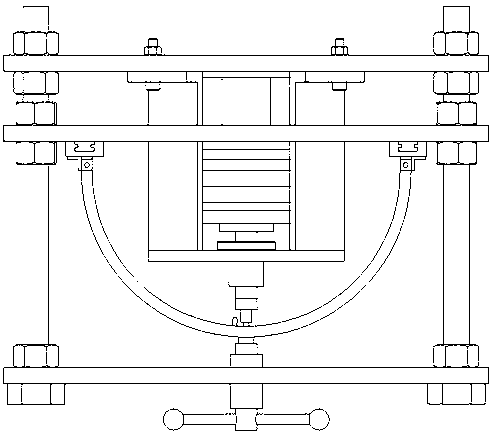

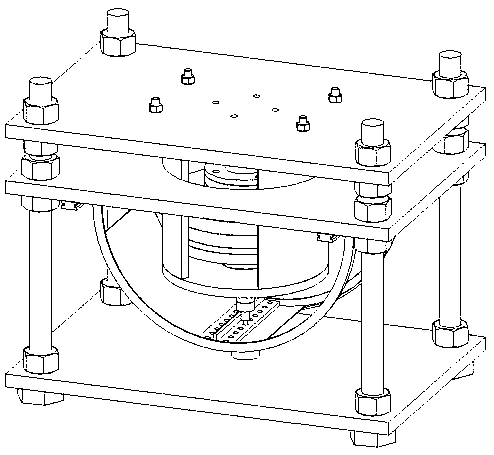

[0038] The invention provides an electromagnetic riveting device for large-scale thin-walled workpieces, such as Figure 1-3 As shown, it includes a screw handle 1, a base plate 2, a pillar screw 3, a screw rod 4, a punch 8, a linear bearing support plate 9, an amplifier 10, a linear bearing 11, a split insert 12, an amplifier partition 13, an electromagnetic Equipment 14, connecting seat 21, spring upper pressing block 22, upper plate 23, return spring 24, center guide rod 28, spring lower pressing block 29, coil carrier plate pressing block 30, coil carrier plate 31, coil insulating glue layer 32, Coil 33, driving plate 34, guide rod sleeve 35, steel sleeve 36 and bracket system 38, the coil insulating adhesive layer 32 is glued and coated on the outside of the coil 33, and the coil insulating adhesive layer 32 can be made of epoxy resin and polyamide The resin is mixed and prepared, and the coil 33 is wound on the coil carrier plate 31 .

[0039] Such as Figure 4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com