A riveting machine for sheet metal parts and its operating method

A technology of sheet metal parts and riveting machines, applied in the field of sheet metal riveting machines, can solve the problems of low work efficiency, cumbersome operation steps, and reduced work efficiency, so as to achieve high work efficiency, expand the application range, and ensure the pressure riveting effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

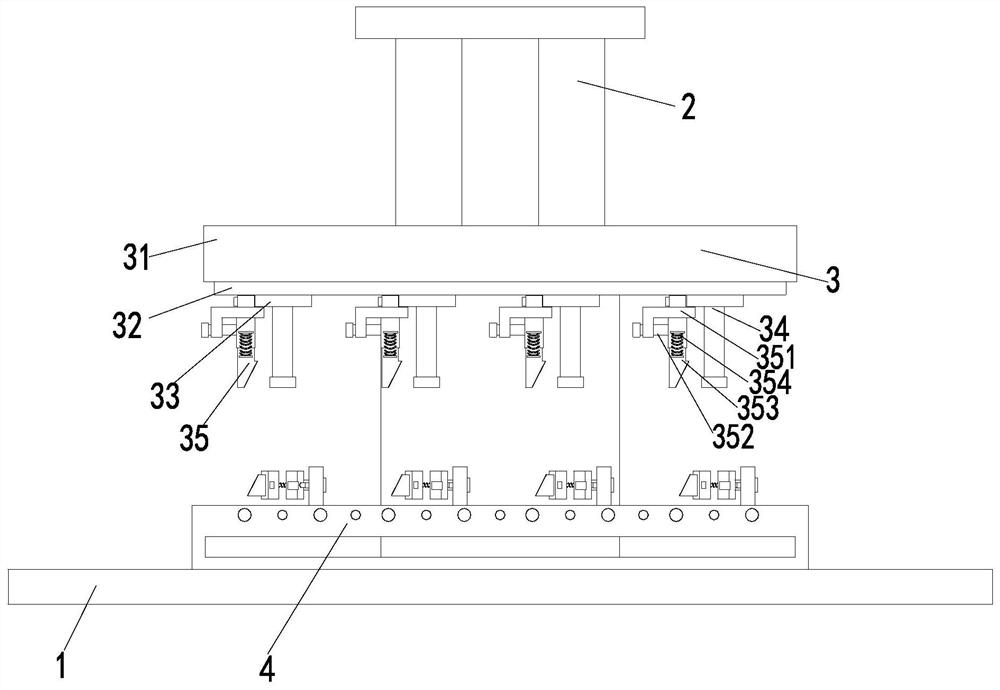

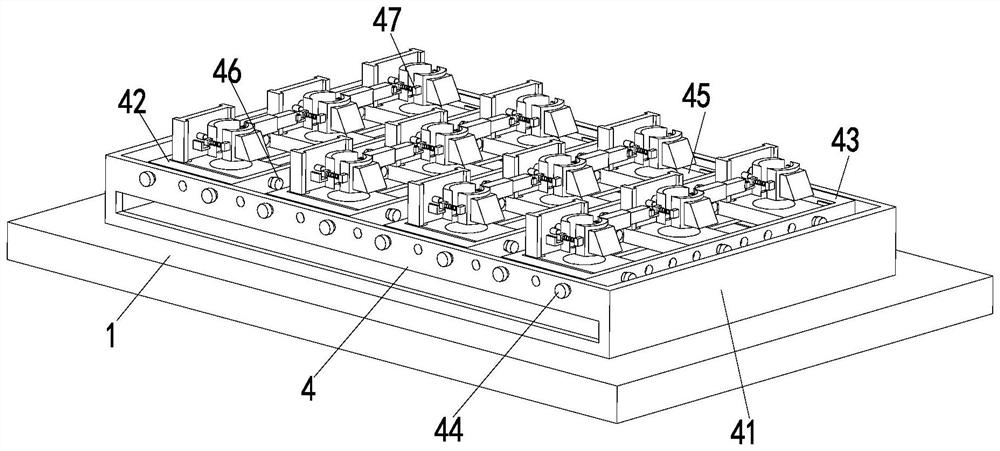

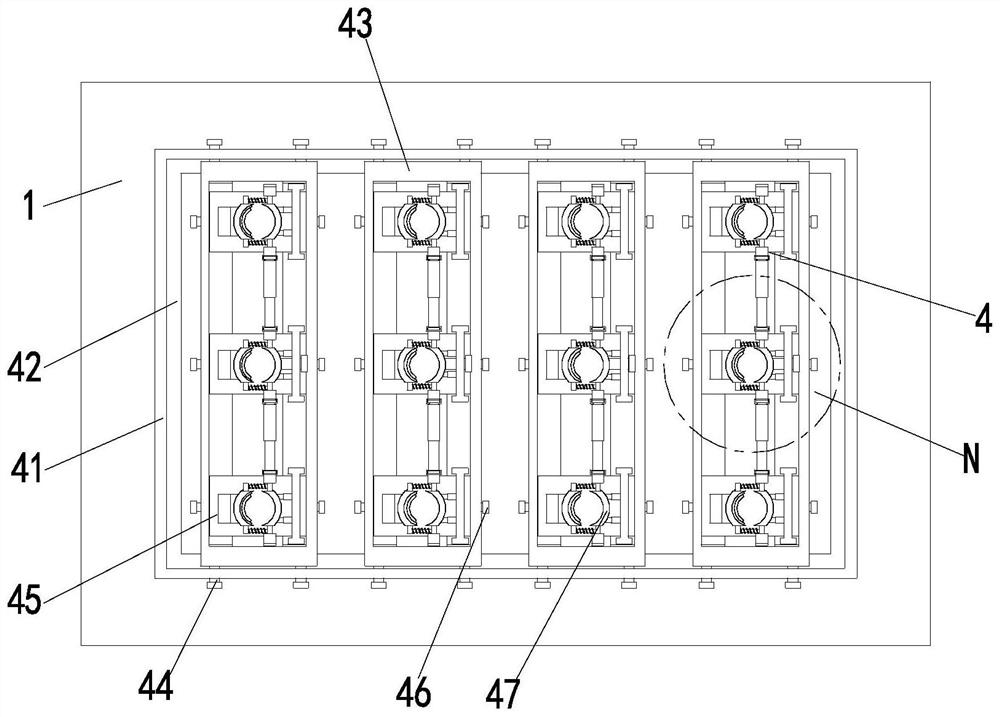

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 4 , to further elaborate the present invention.

[0033] A riveting machine for sheet metal parts, comprising a workbench 1, a pneumatic frame 2, a riveting mechanism 3 and a guide mechanism 4, the upper end of the workbench 1 is equipped with a pneumatic frame 2, and the pneumatic frame 2 is an up-and-down retractable structure , the lower end of the pneumatic frame 2 is equipped with a riveting mechanism 3, the lower end of the riveting mechanism 3 is arranged with a guiding mechanism 4, and the guiding mechanism 4 is installed on the workbench 1; the structure, principle and control method of the pneumatic frame 2 are all prior art ,in:

[0034]Described riveting mechanism 3 comprises patrix 31, moving plate 32, moving block 33, pressure riveting head 34 and auxiliary frame 35, and patrix 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com