Riveting-assisted rotary friction welding process for dissimilar metal bar and application

An auxiliary rotation and dissimilar metal technology, applied in the field of material processing, can solve the problems of interface radial heat production rate, temperature distribution difference, insufficient interface metallurgical reaction, interface structure and performance unevenness, etc., and achieve the effect of excellent process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

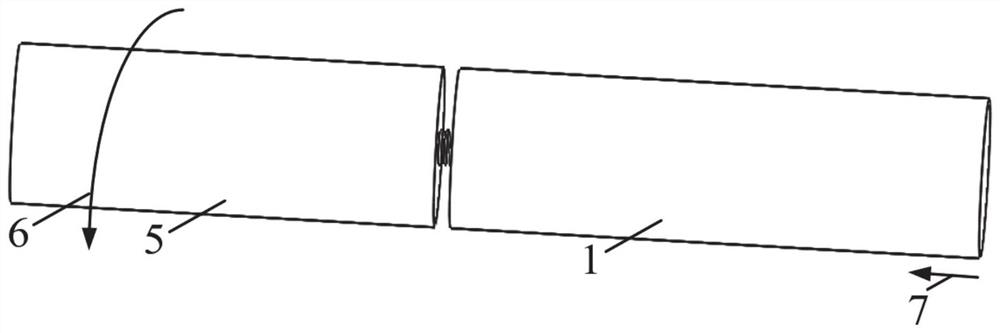

[0047]The high-quality and high-efficiency connection of aluminum alloy and steel bars with a diameter of 15mm is achieved by using the riveting-assisted inertial friction welding process. The connection strength is significantly higher than that of the aluminum / steel dissimilar metal joints prepared by the conventional friction welding process.

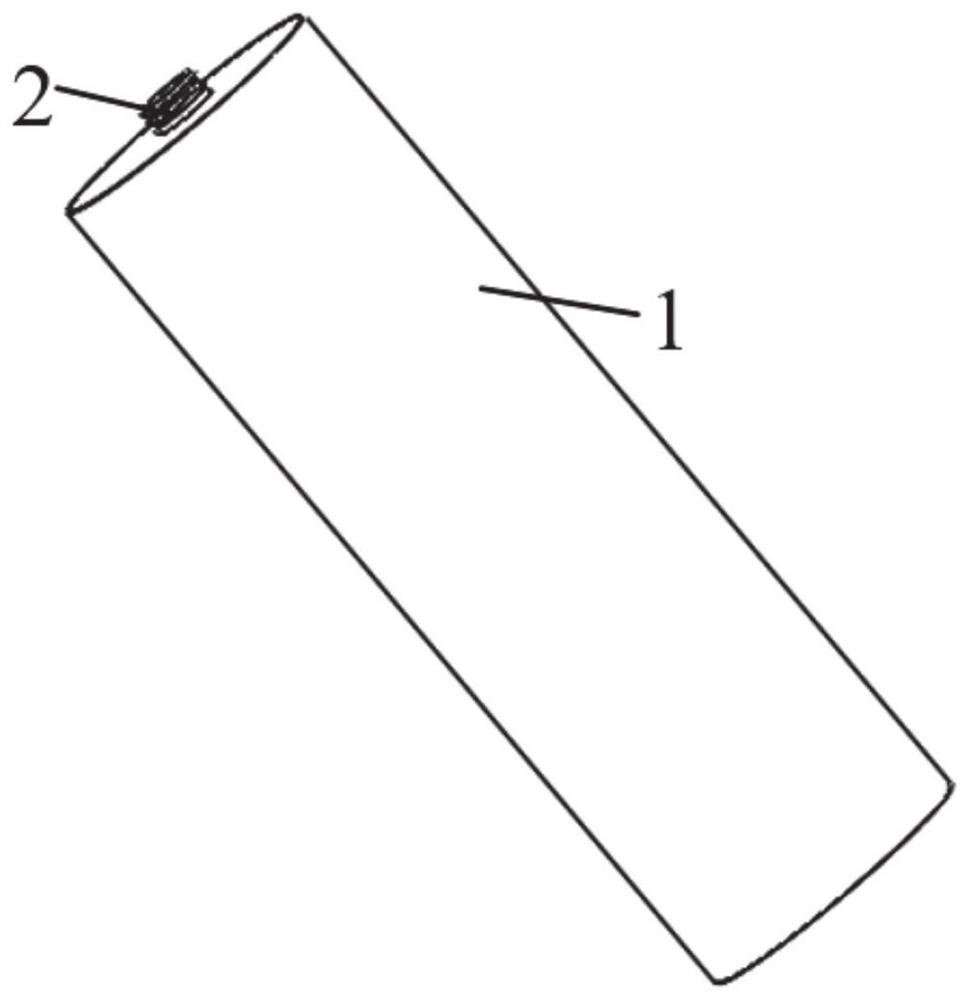

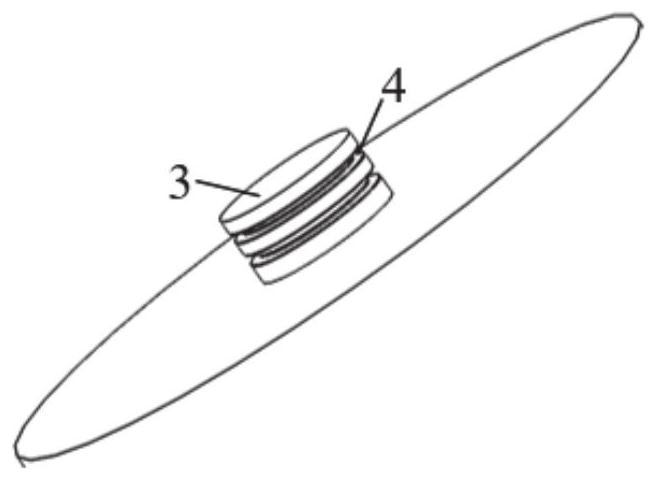

[0048] (1) Bar preparation: The aluminum alloy bar selected for the test is in the 6061-T6 state, and the stainless steel is in the solid solution treatment state of 304 stainless steel. The aluminum alloy rod only uses machining to remove the oxide film on the end face to obtain a flat end face. For steel bars, use a high-precision lathe end face grooving tool to process a cylinder with a height of 1mm and a diameter of about 3.5mm; then replace it with a triangular turning tool, and process grooves with a depth of 0.40mm every 1mm on the side of the cylinder; Finally, remove the oxide film on the end surface of the stud and process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com