Microphone pin and method for connection it with printed circuit board

A printed circuit board and microphone technology, which is applied in the direction of microphone mouth/microphone accessories, etc., can solve the problems of conductive layer damage, poor contact, conductive layer falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

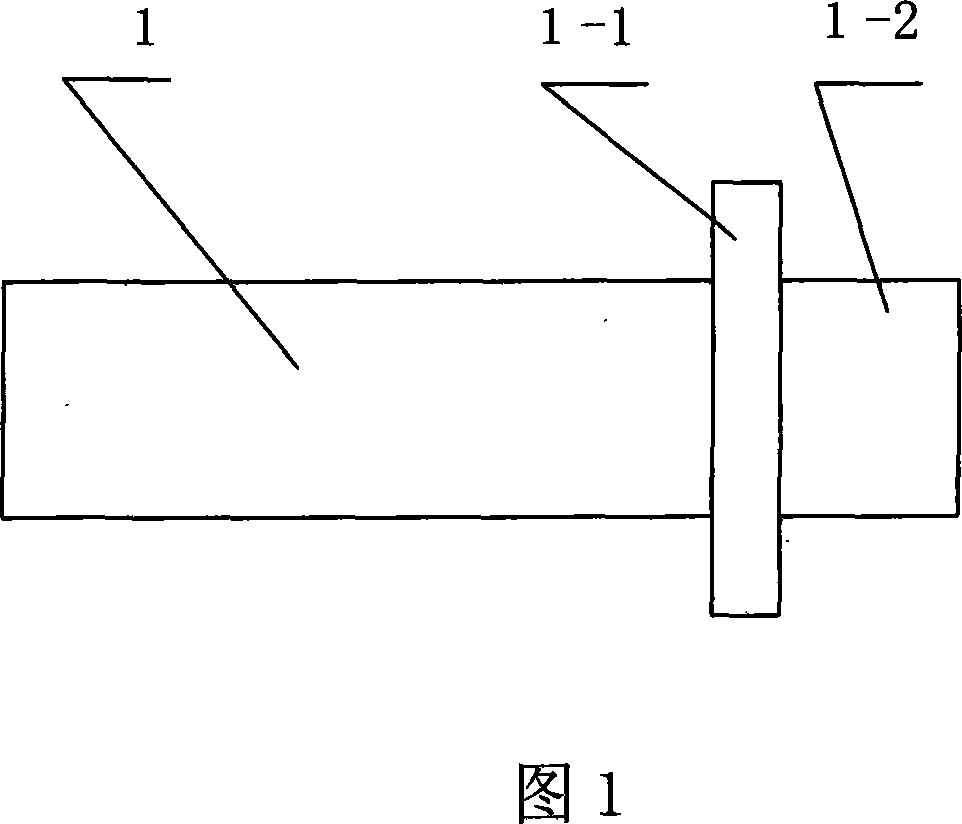

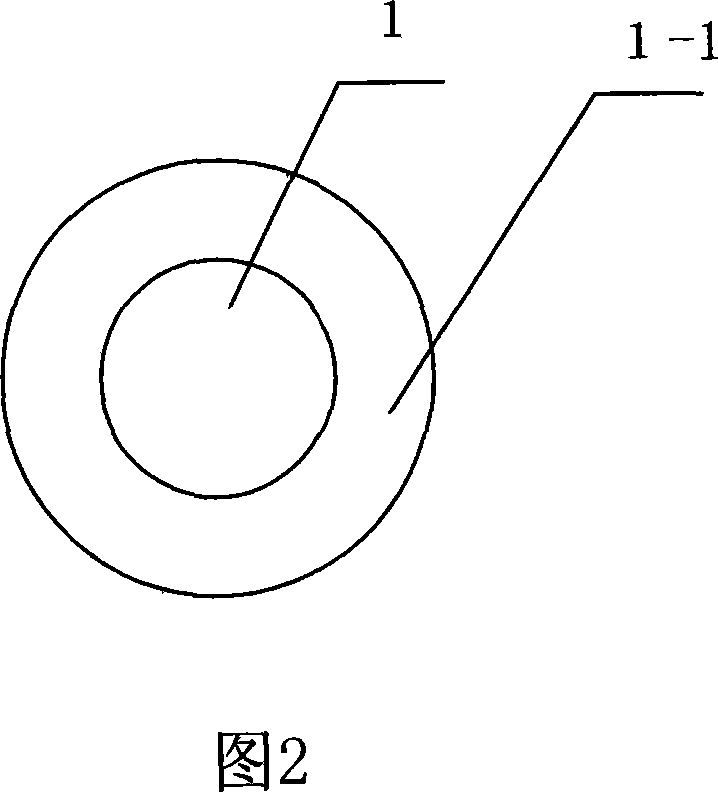

[0014] As shown in Figures 1 and 2, a microphone pin includes a pin body 1. The front part of the pin body 1 is a connection area 1-2 that matches the jack of the printed circuit board. The region of the connecting region 1-2 has a shoulder 1-1. The shoulder 1-1 can be single-layer or double-layer.

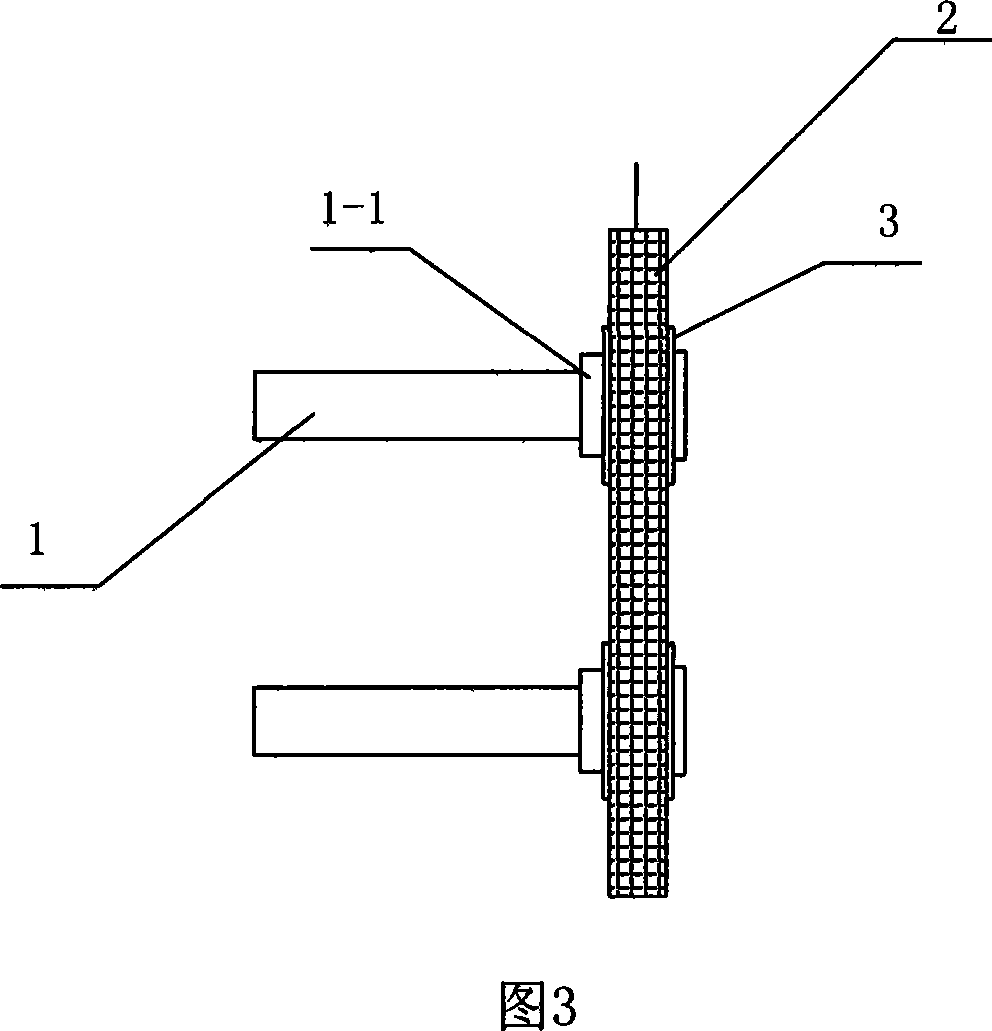

[0015] As shown in Figures 3, 4, and 5, a method for connecting a microphone pin to a printed circuit board, the steps are: first insert the front part 1-2 of the microphone pin into the reserved hole on the printed circuit board 2, and lead The feet are matched with the reserved holes, and the front ends of the pins are exposed from the reserved holes, and then the front ends of the pins are riveted with the printed circuit board by riveting. Since the pin fits with the reserved hole, the pin will not damage the conductive layer on the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com