Connecting structure and wiper using connecting structure

A technology for connecting structures and connecting parts, which is used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of high material requirements, difficult to maintain performance, and short service life of stainless steel sheets, and achieve long service life and pressure. Even distribution and strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

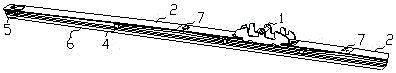

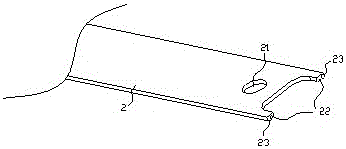

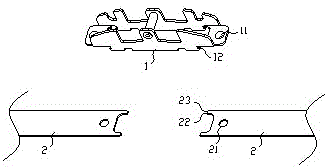

[0027] Such as image 3 As shown, a connecting structure is arranged between the connecting part of the wiper arm and the shrapnel, which includes:

[0028] At least one connecting riveting part, the connecting riveting part includes a male riveting part arranged on the wiper arm connector 1 and a female riveting part arranged on the elastic piece 2;

[0029] A limiting part, the limiting part is arranged between the wiper arm connecting part 1 and the elastic piece 2, and the limiting part is used to limit the wiper arm connecting part 1 and the elastic piece before riveting 2, so as to align the male riveting part and the corresponding female riveting part.

[0030] Such as image 3 As shown, the male riveting part is a male riveting hole 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com