Nut cap riveting die

A technology for riveting molds and caps, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inconvenient positioning of caps and difficult riveting, and achieve the effects of simple structure, good return effect and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

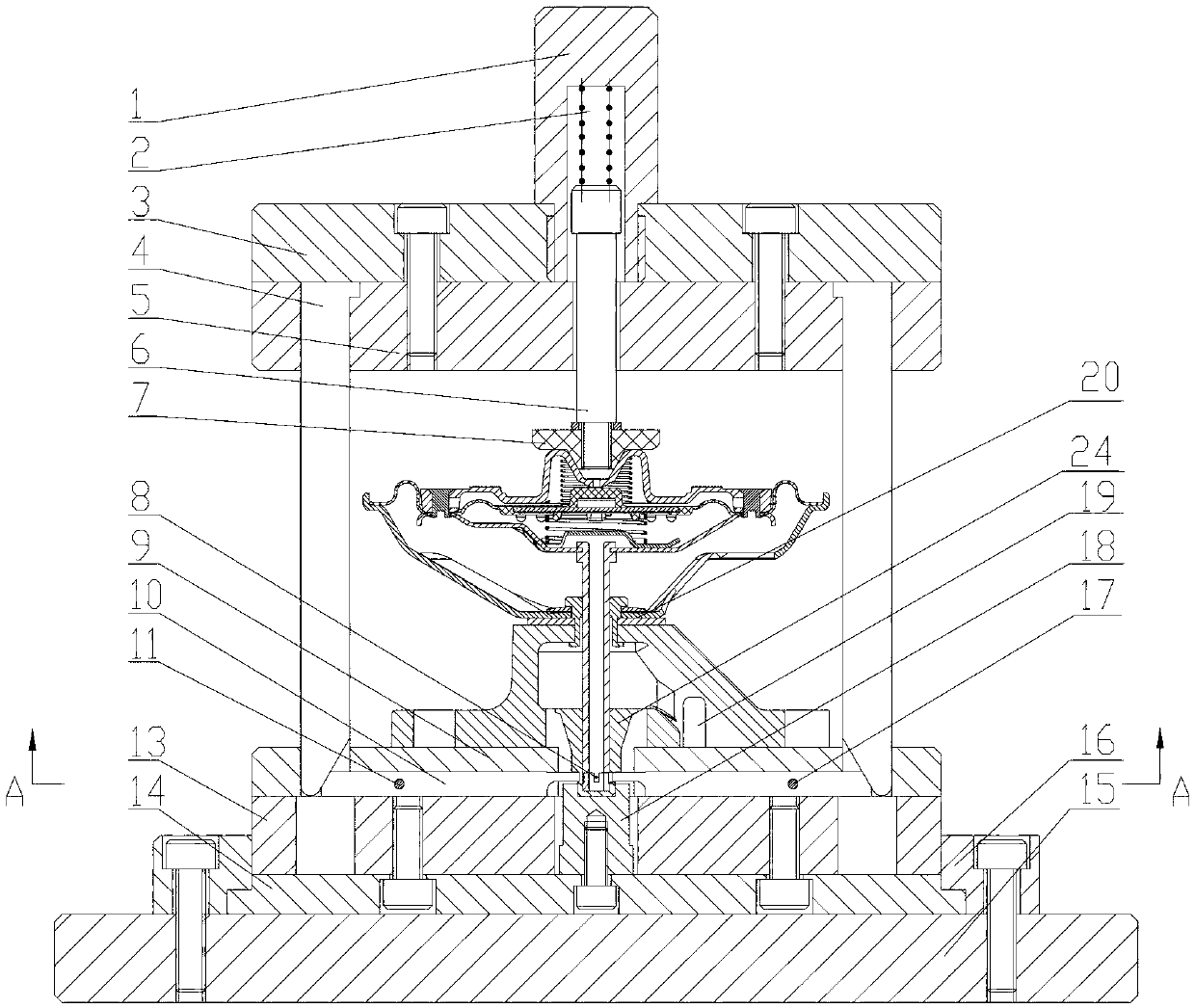

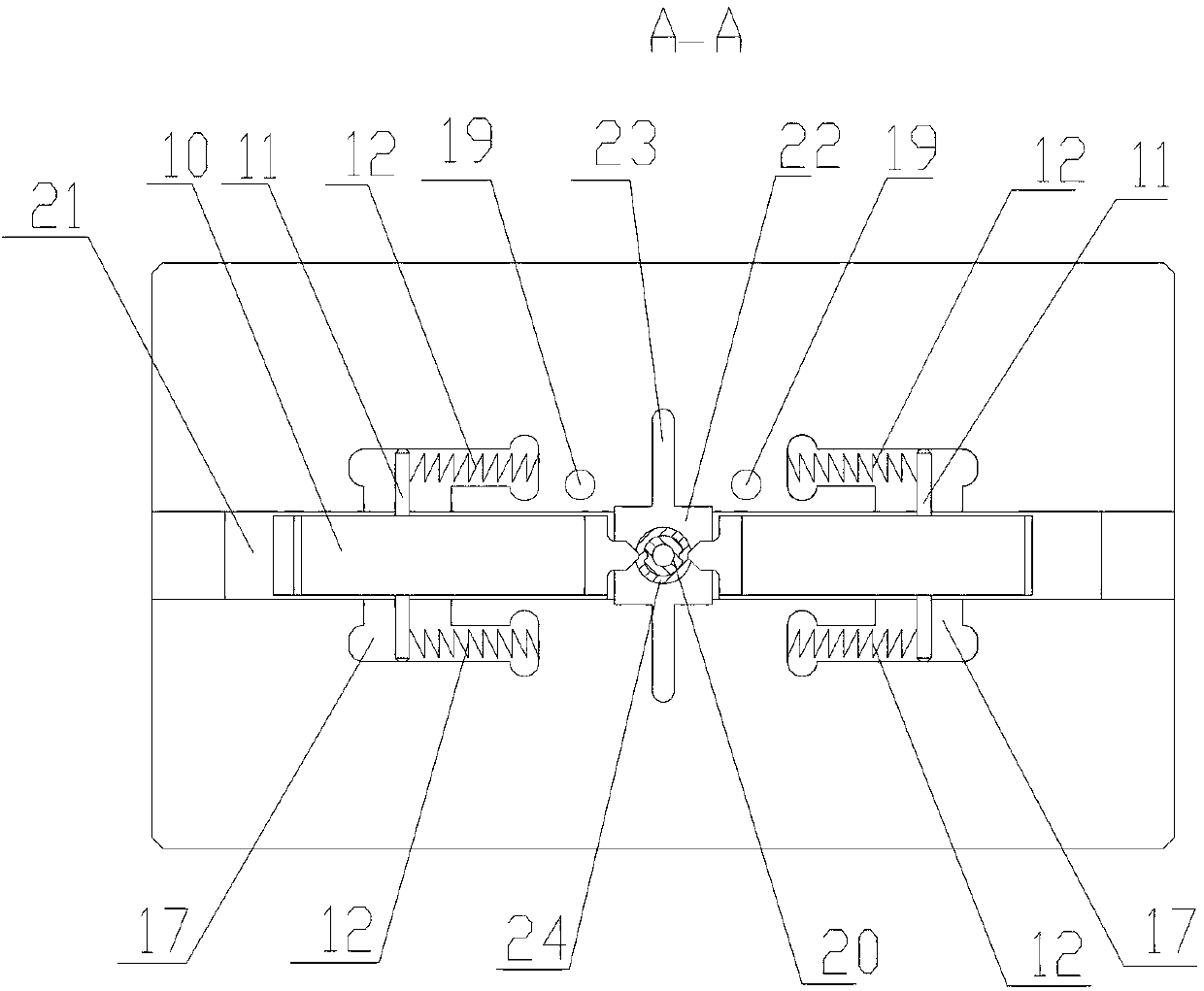

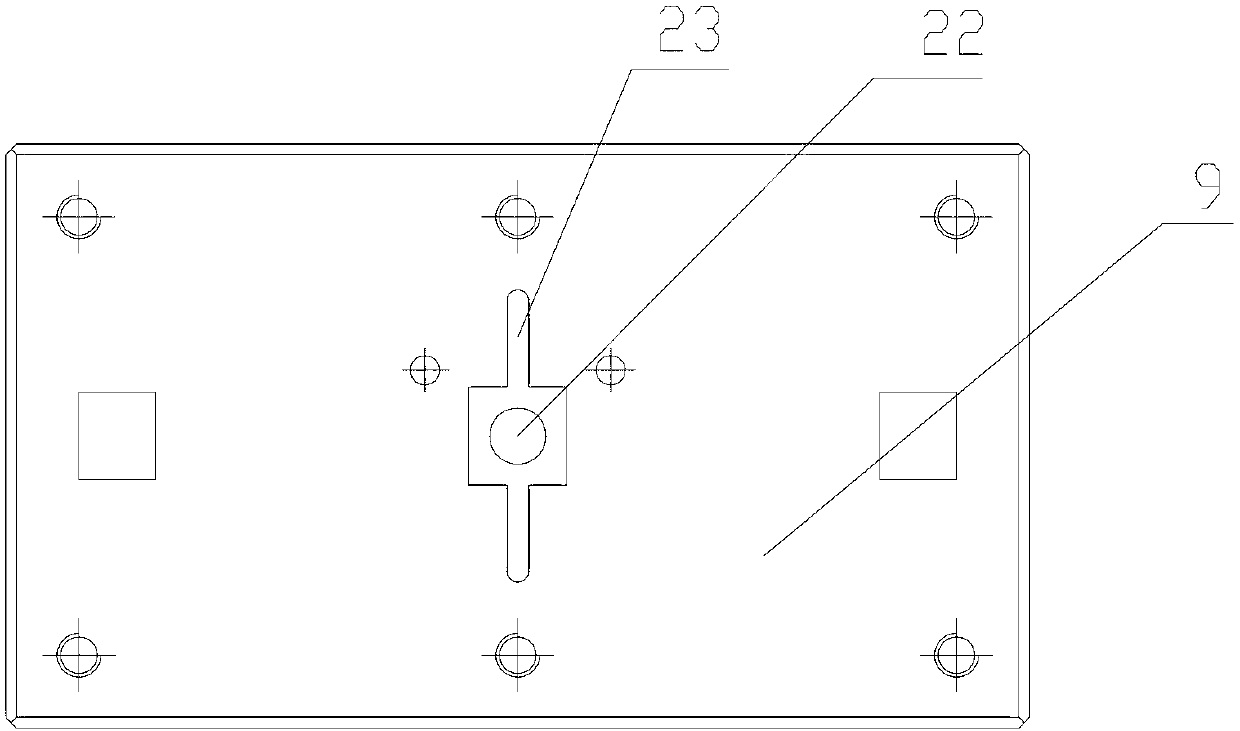

[0017] Examples such as Figures 1 to 3 Shown, a kind of cap riveting die comprises patrix, lower die, and lower die comprises base plate 15, the supporting plate 14 that is fixed on the base plate 15 by guide plate 16, the backing plate 13 that is fixed on the supporting plate 14 by bolt, is installed on The positioning plate 9 on the backing plate 13; the side of the positioning plate 9 in contact with the backing plate 13 is provided with a rectangular groove 21, and the positioning plate 9 is located in the middle of the rectangular groove 21 and has a through hole 22 for placing the workpiece 20; In the rectangular groove 21 and on both sides of the through hole 22, a punch 10 is respectively installed; two stop grooves 17 vertical to the rectangular groove 21 are also arranged on the positioning plate 9, and the width of the stop groove 17 is the same as that of the punch. The stroke of 10 is adapted; the described punch 10 is provided with a cylindrical pin 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com