Automotive light driving lever punching point closing riveting die with CCD visual inspection systems

A visual inspection and automotive technology, applied in the direction of forming tools, manufacturing tools, feeding devices, etc., can solve problems such as relative rotation and displacement between casing and casting, failure to meet design requirements, product size changes, etc., to achieve reduction Visual fatigue, improve product qualification rate, accurate and reliable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

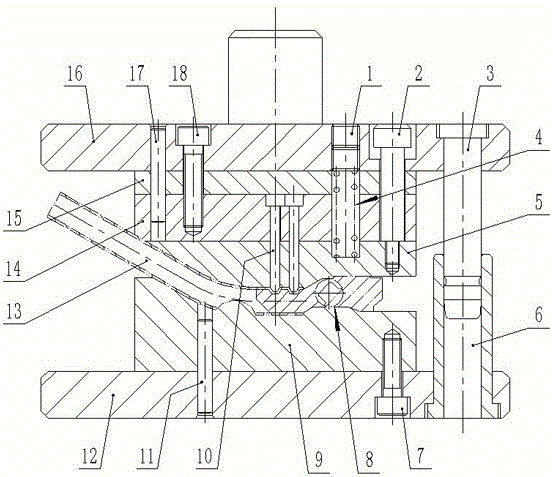

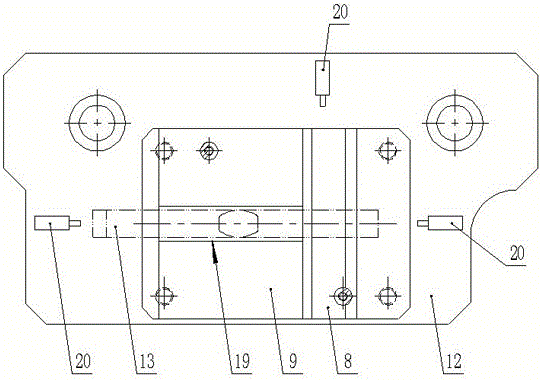

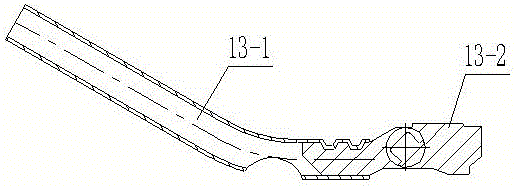

[0013] The upper mold part is connected by the upper template 16, the fixed plate 14 fixed on the back of the upper template by the third screw 18 and the second positioning pin 17, two punches 10 fixed on the back of the fixed plate, and connected by the first screw 2. The unloading plate 5 on the back side of the fixed plate 14 is formed; the back side of the unloading plate has an arc surface matching the shape of the workpiece 13, a spring 4 is arranged between the unloading plate and the upper template 16, and two punches 10 pass through the unloading plate. The material sheet 5 protrudes downwards. The lower mold part is composed of a lower template 12, a female mold 9 fixed on the surface of the lower template by the first positioning pin 11 and the second screw 7, and the surface of the female mold has a positioning groove 19 and a positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com