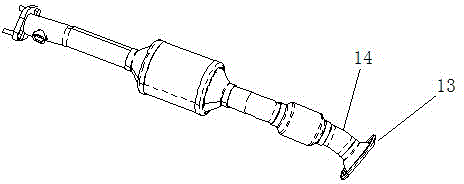

Clamping mechanism for welding automobile exhaust pipe end flange

A flange welding and automobile exhaust technology, applied in the field of fixtures, can solve the problems of lack of exhaust pipes and flanges, difficult automatic welding, etc., to achieve accurate and reliable positioning and clamping, convenient operation, accurate and fast positioning and clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

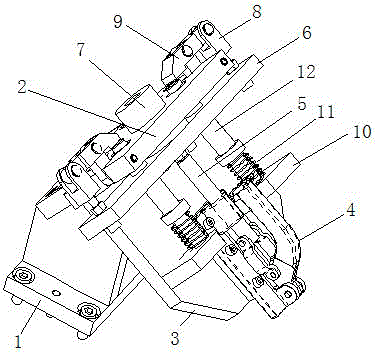

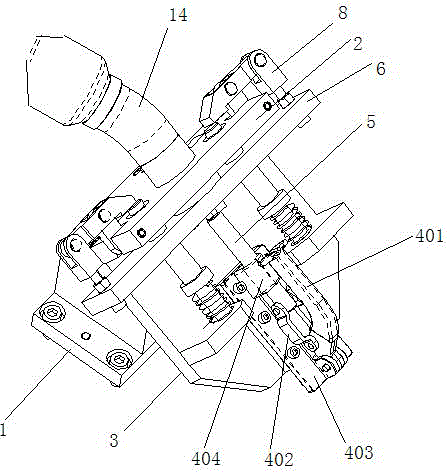

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] like figure 2 shown.

[0017] A clamping mechanism for flange welding at the end of an automobile exhaust pipe, which includes a base 1, on which a flange positioning panel 2 with an adjustable inclination angle is installed, and the flange positioning panel 2 is connected with a support plate 3, the support plate 3 is equipped with a quick clamping mechanism 4, the driving rod 5 of the quick clamping mechanism 4 is connected with a connecting plate 6 that can move in parallel with the flange positioning panel 2 under the drive of the driving rod, and the middle part of the connecting plate 6 is equipped with a connecting plate that can pass through The exhaust pipe positioning pin 7 of the exhaust pipe positioning hole of the flange positioning panel 2, a pressure claw push block 8 is respectively installed on both sides of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com