New stud structure

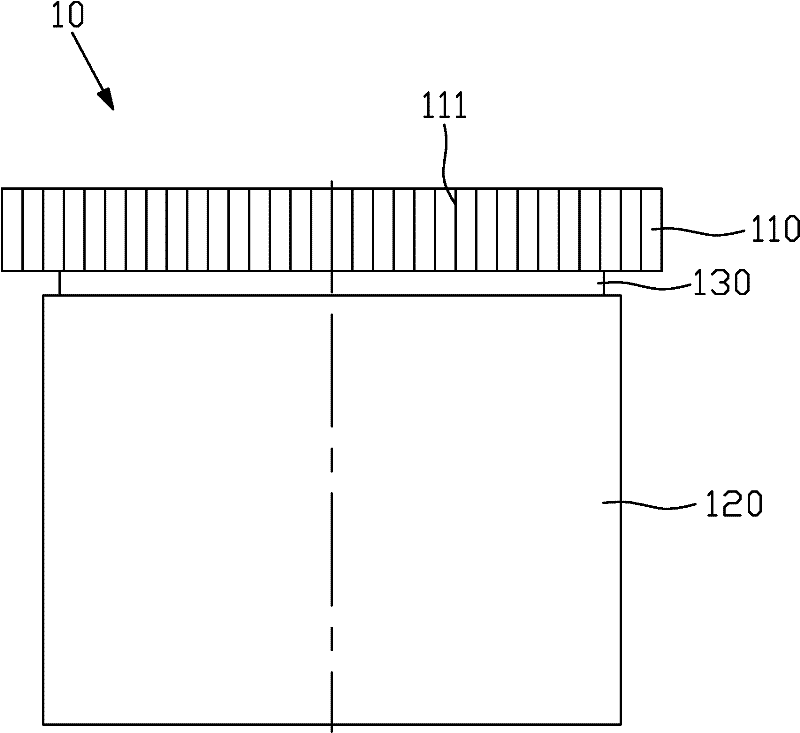

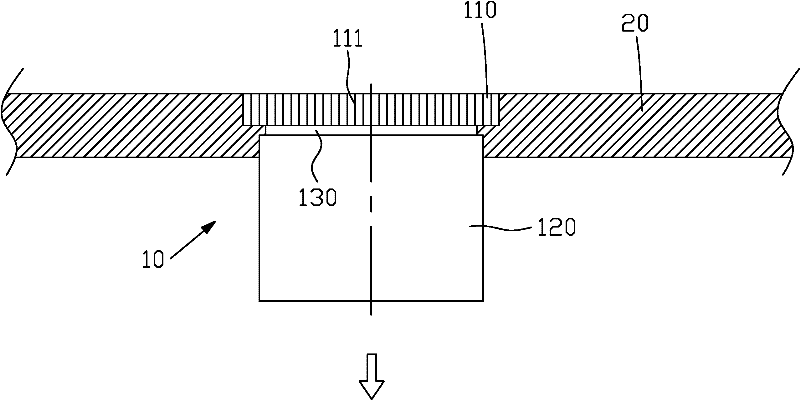

A new type of stud technology, applied in the direction of rivets, can solve the problems that the stud structure 10 cannot be riveted in, and the riveting splines 110 are easily broken, and achieve the effect of easy riveting and thin riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

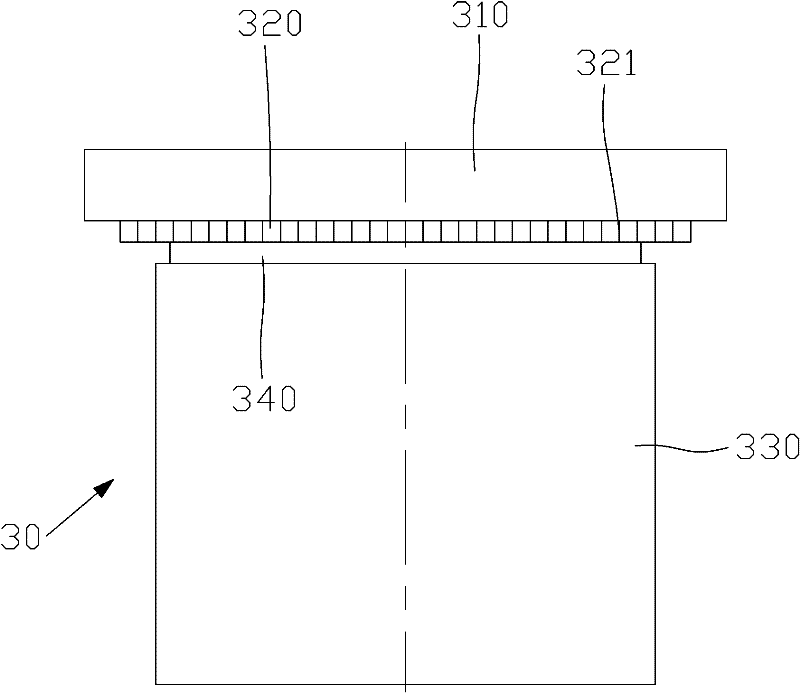

[0014] see image 3 As shown, it depicts a schematic diagram of the novel stud structure of the present invention. In this embodiment, the novel stud structure 30 of the present invention is applied to riveting products. The novel stud structure 30 includes successively smaller diameters. An anti-tension ring 310, a riveting spline 320, a cylinder 330 and a extrusion trough 340, the anti-tension ring 310, riveting spline 320, extrusion groove 340 and cylinder 330 are connected in sequence, The riveting flower tooth 320 is provided with a gear-shaped structure 321, and the thickness of the riveting flower tooth 320 is relatively thin, while the thickness of the tension ring 310 is relatively thick. In this embodiment, the riveting flower tooth 320 The thickness is 0.3 mm, and the thickness of the tension ring 310 is 1 mm.

[0015] When riveting this new stud structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com