Riveting tool

A riveting tooling and riveting technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of potential safety hazards, low efficiency, and inability to realize riveting, so as to improve production efficiency and realize the effect of one-time molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

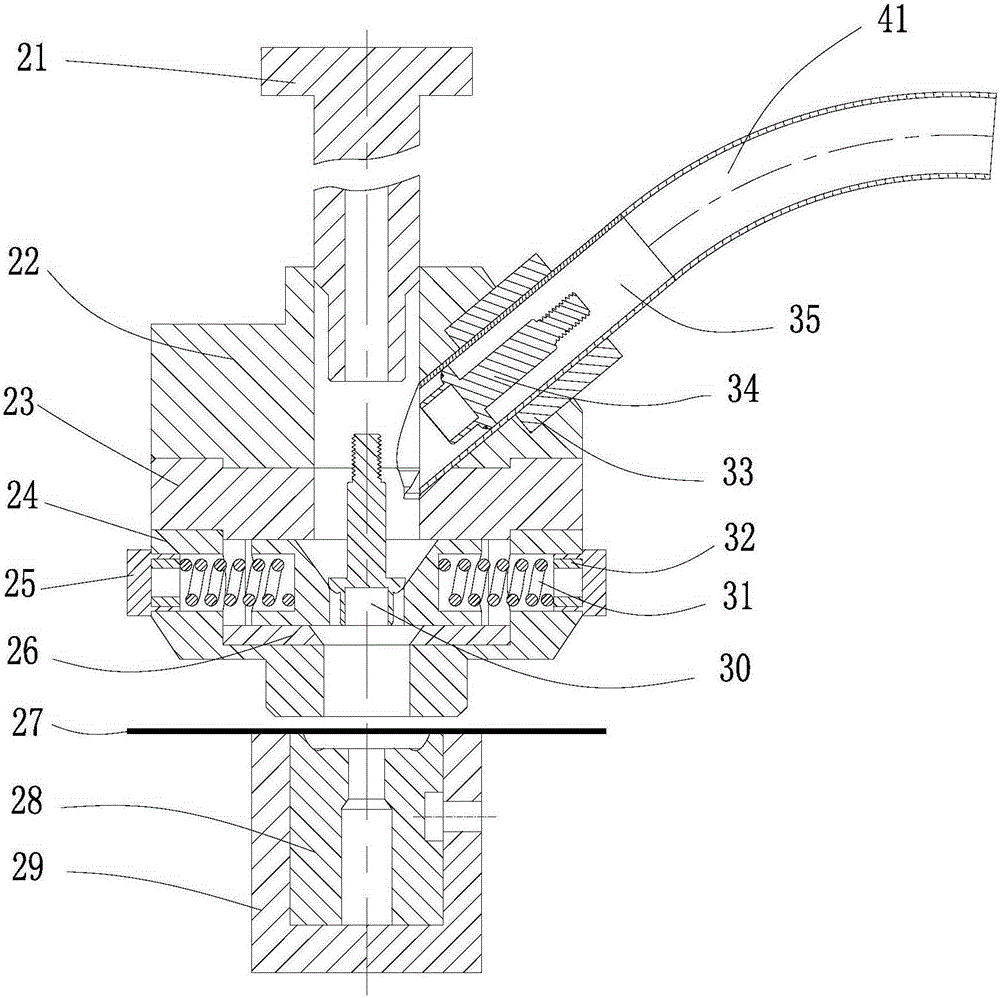

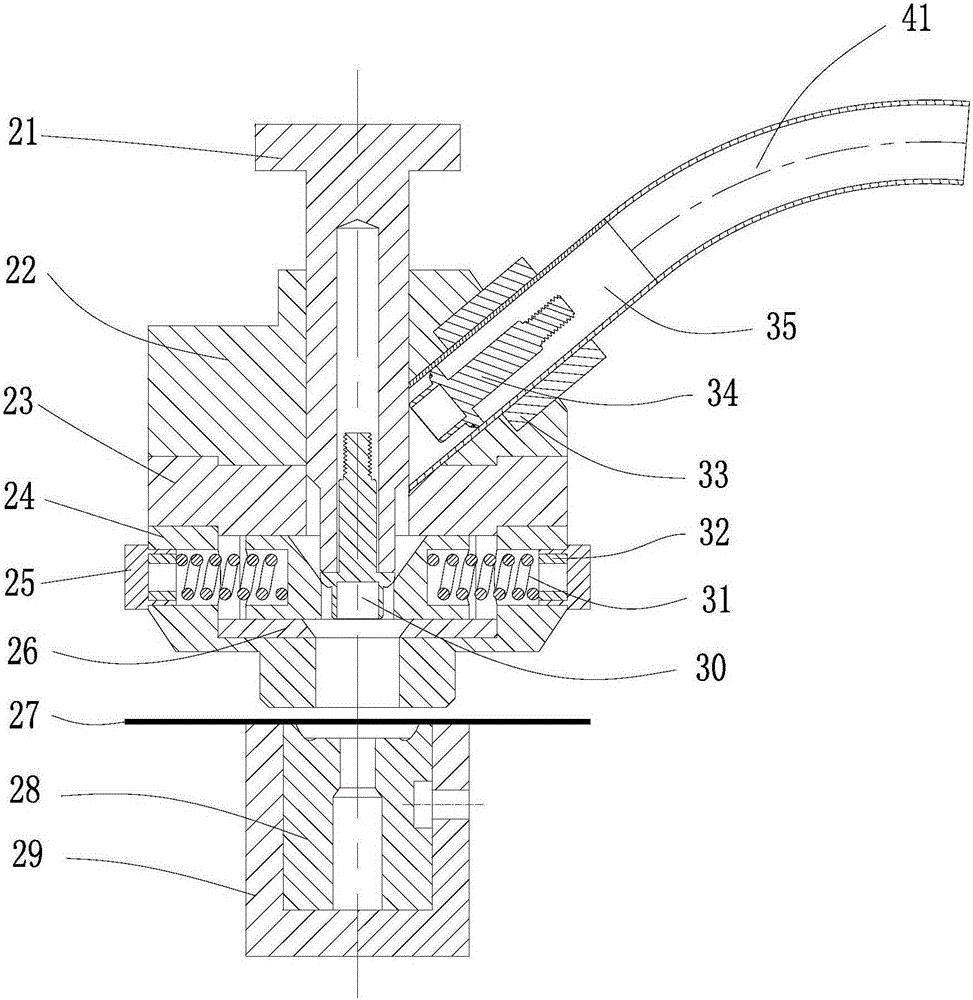

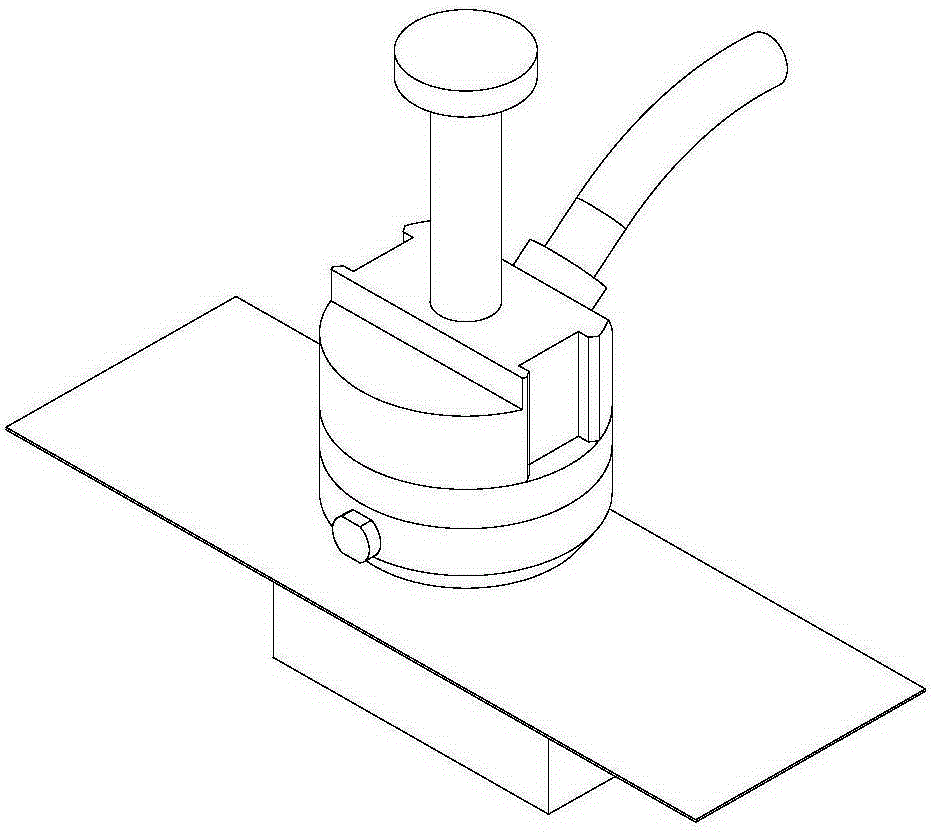

[0035] see first Figure 1-3 , the present invention provides a riveting tool for realizing the riveting operation of riveting bolts, which generally includes an upper mold assembly (for example, including 22, 23, 24, etc. in the illustrated embodiment) and a push rod 21, The front end (the lower end in the figure) of the ejector rod 21 is slidably inserted in the ejector rod hole in the upper die assembly, so as to slide downward under the drive of an external power device (such as a press), thereby pushing The riveting bolt 30 moves down to complete the riveting. For the convenience of feeding, the upper mold assembly of the present invention is also provided with a feed channel (for example, at the position of reference numeral 35), and the feed channel intersects with the ejector pin hole obliquely downwards, thereby When the push rod 21 is in the raised position (that is, when the feed passage is not blocked), the riveted bolt 34 to be riveted can slide into the push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com