Patents

Literature

31results about How to "Continuous automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

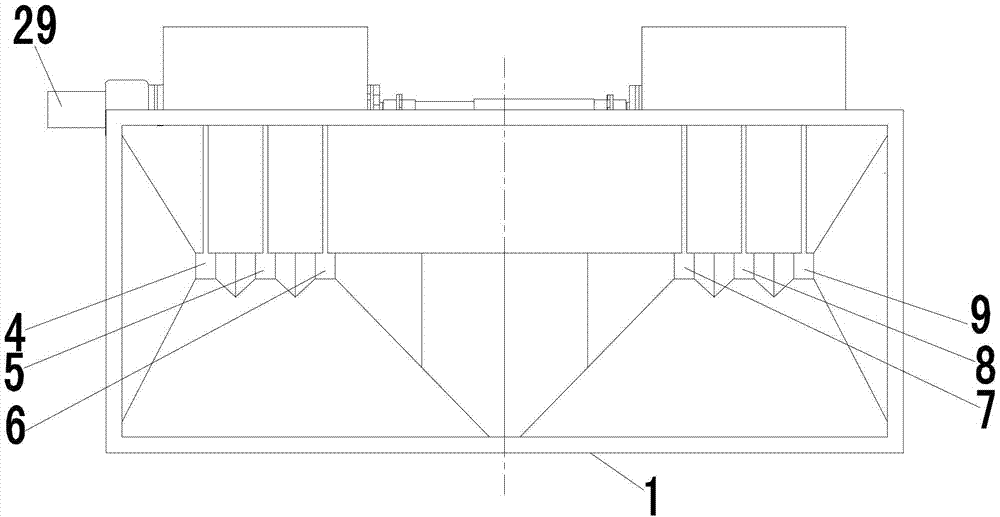

Efficient fertilizer mixer for agriculture

InactiveCN105536600AImprove mixing efficiencyQuality improvementRotary stirring mixersTransportation and packagingEngineeringMixing effect

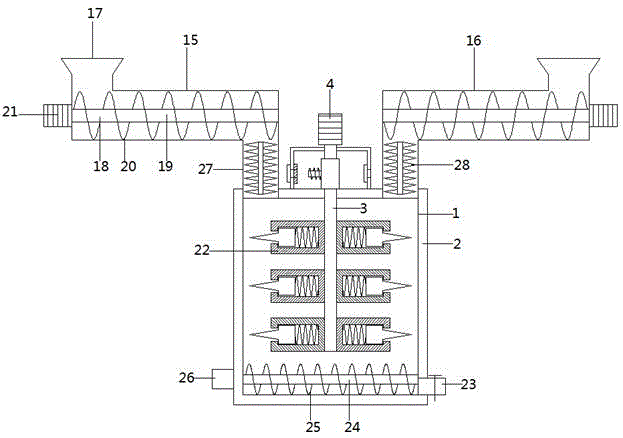

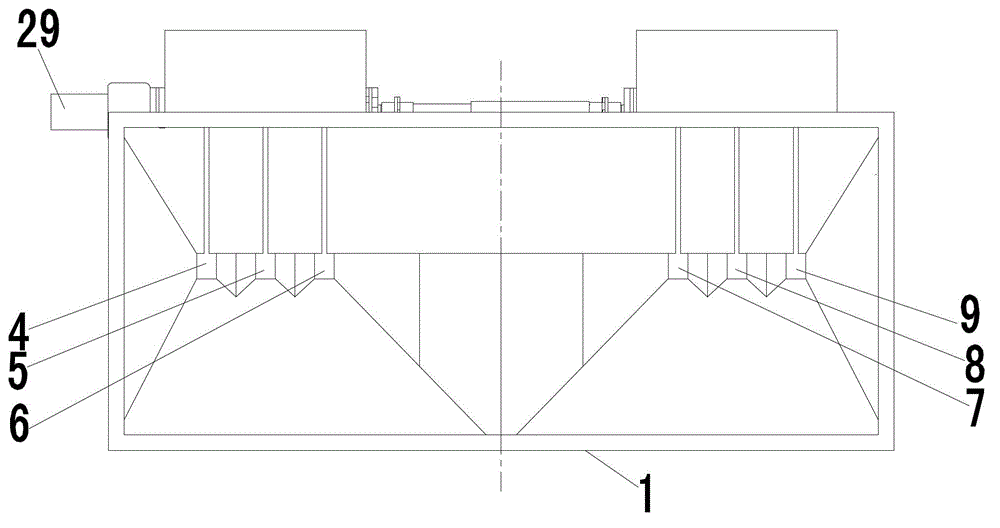

The invention discloses an efficient fertilizer mixer for agriculture. The mixer comprises a mixer body, wherein feeding ports are formed in left and right ends of the upper surface of the mixer body; a first feeding barrel and a second feeding barrel are arranged at left and right ends of the upper side of the mixer body respectively; feeding ports of the first feeding barrel and the second feeding barrel are both connected with feeding hoppers; screw feeding mechanisms are horizontally arranged in inner axis positions of the first feeding barrel and the second feeding barrel; each screw feeding mechanism comprises a horizontal rotating shaft and a screw blade arranged on the outer wall of the rotating shaft, and the rotating shaft is electrically connected with a first motor. The efficient fertilizer mixer for agriculture can realize automatic feeding and discharging, the working efficiency of the mixer is greatly improved, fertilizer can be crushed before mixing, the quality of the fertilizer is improved, the mixing effect is good, full mixing can be realized, besides, stirring rotating shafts can be cooled, cooling can be performed without halt, the working efficiency of the mixer is improved, and the service life of the stirring rotating shafts is prolonged.

Owner:李秋琦

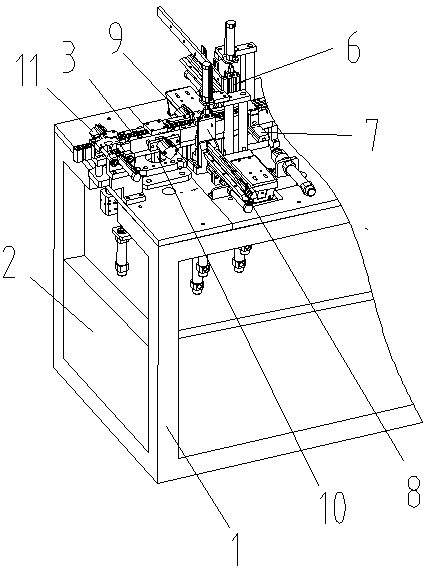

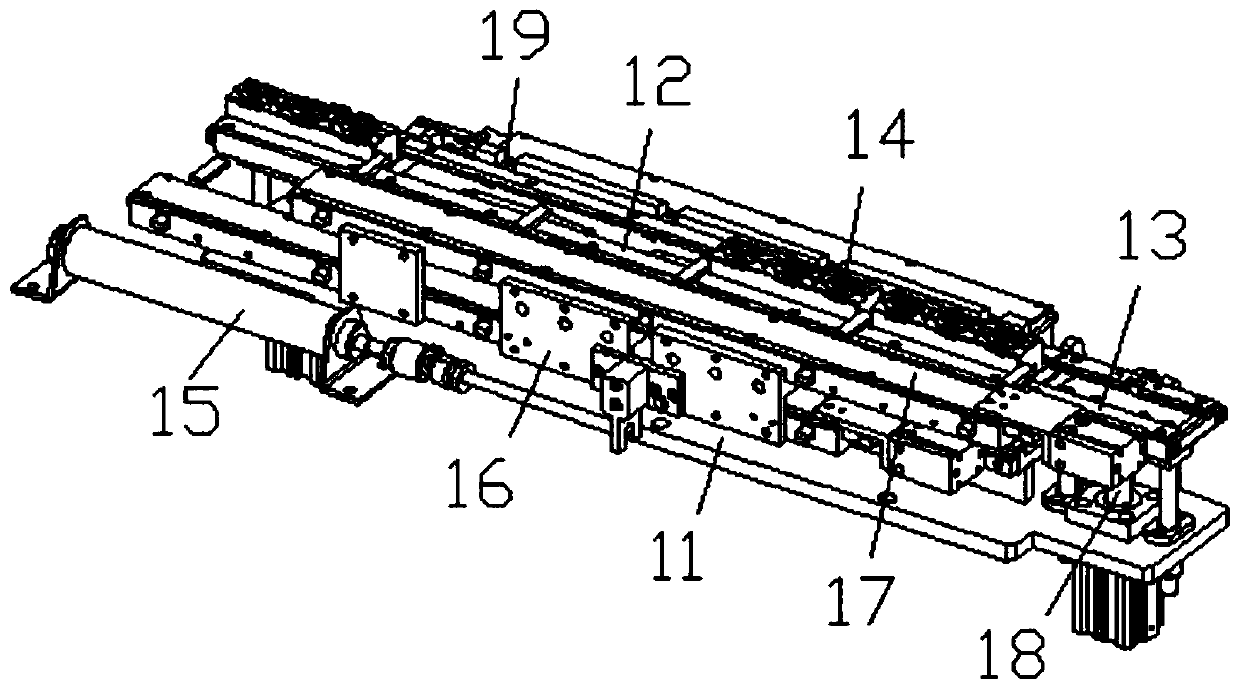

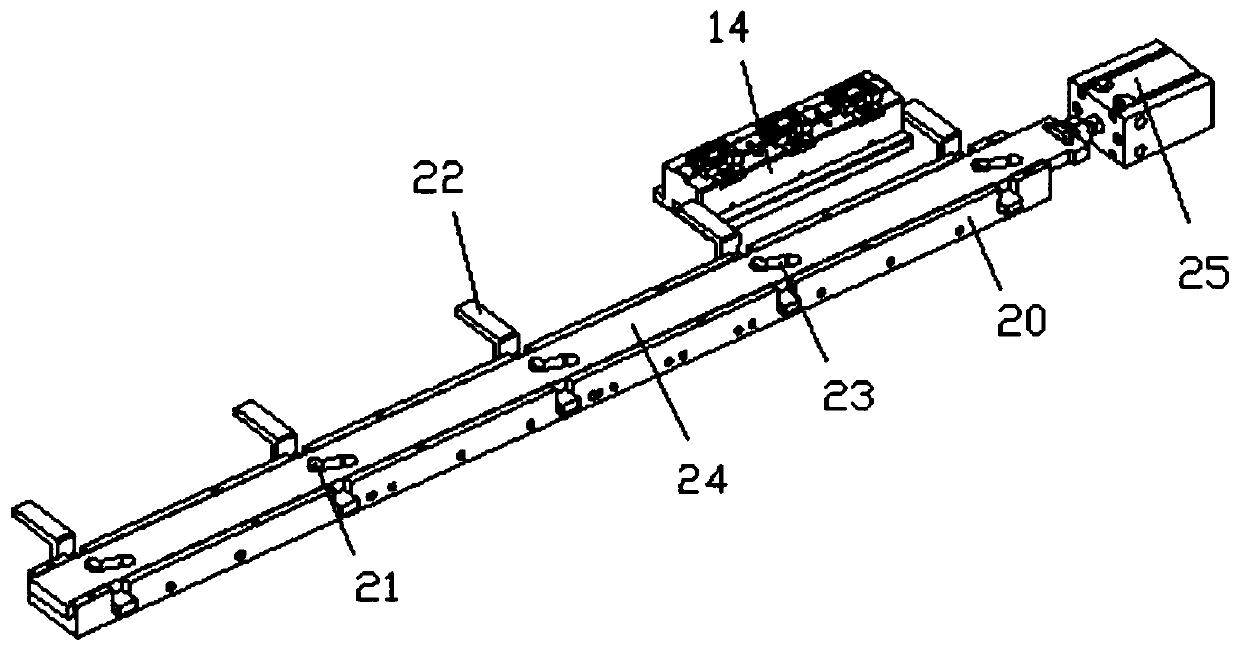

Riveting tool

Owner:GREE ELECTRIC APPLIANCES INC

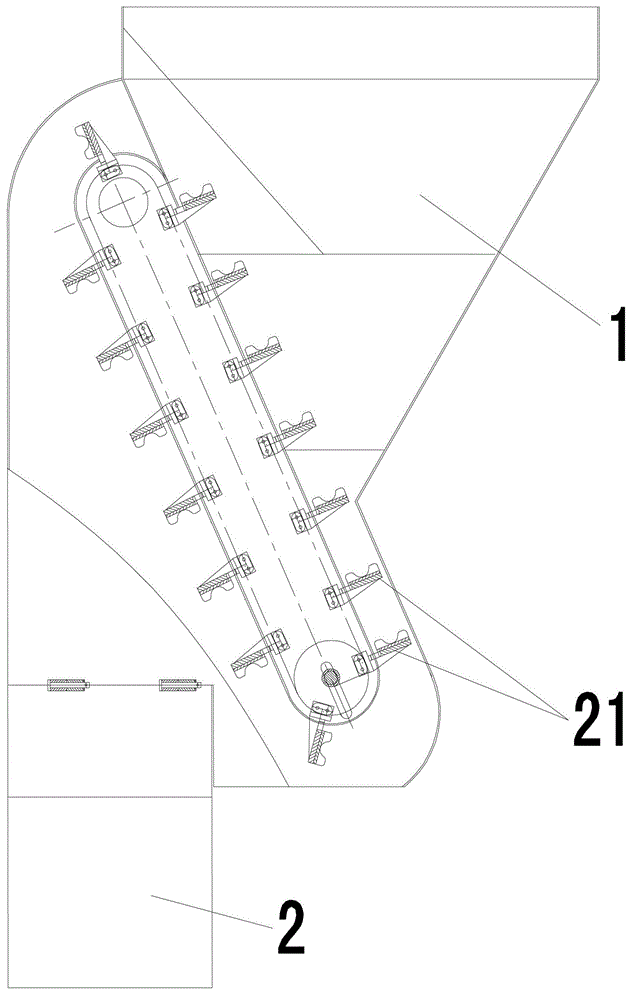

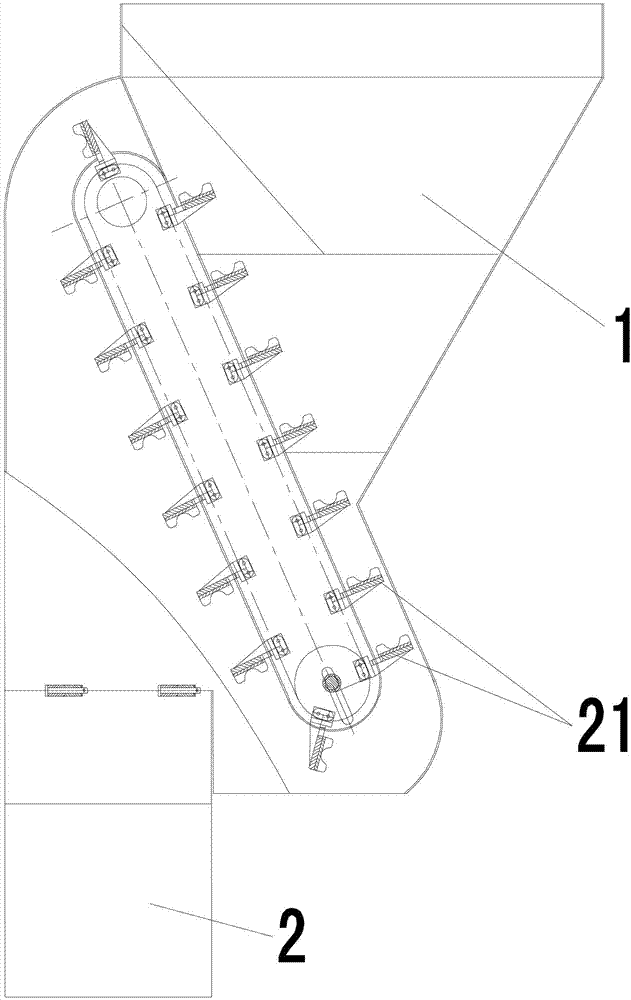

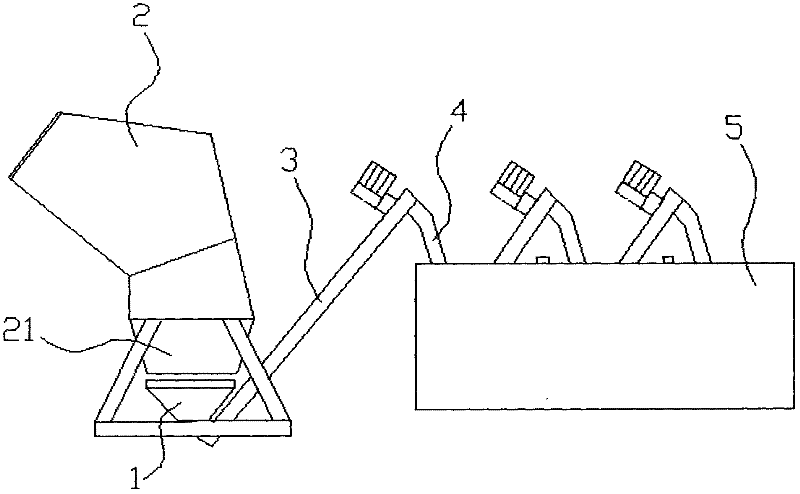

Seeding apparatus for planting single-bud sugarcanes

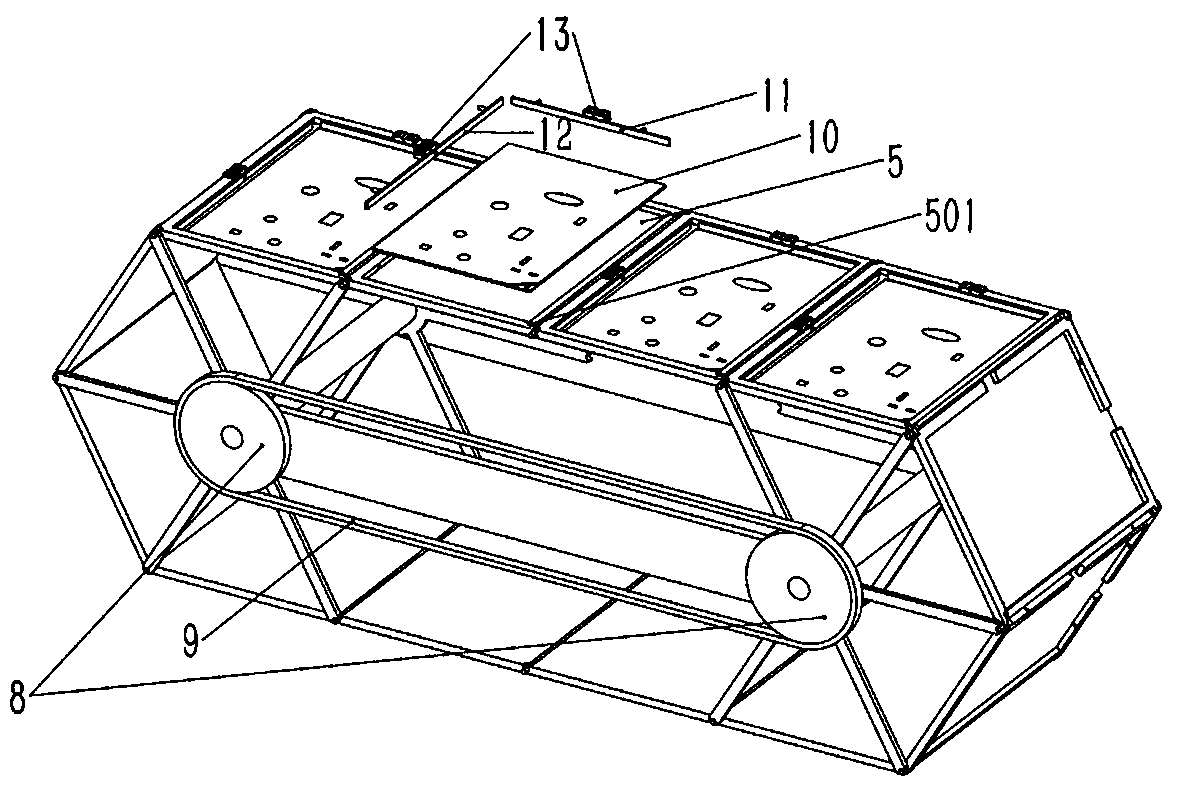

The invention discloses a seeding apparatus for planting single-bud sugarcanes. The seeding apparatus comprises a seed box, a hydraulic drive assembly, a seed bud conveying drive device, a tensioning gear, a feeding passage port and a sugarcane guide opening, wherein the hydraulic drive assembly is arranged at one side of the seed box and provides power to the seed bud conveying drive device; the tension device adjusts the tension degree of the seed bud conveying drive device; the feeding passage port is arranged inside the seed box; and the sugarcane guide opening is arranged on the feeding passage port and is connected with the seed box. The seeding apparatus can effectively solve the problems of high labor intensity of sugarcane planting, low work efficiency, high planting cost, low sugarcane planting efficiency and the like in the prior art, and has the characteristics of being simple in structure, simple and convenient to operate, even to feed, continuous and automatic to feed in planting of the single-bud sugarcanes, high in mechanical degree, high in production efficiency and the like; and physical labor is alleviated.

Owner:SOUTH CHINA AGRI UNIV

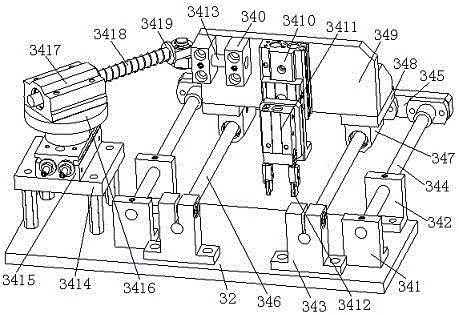

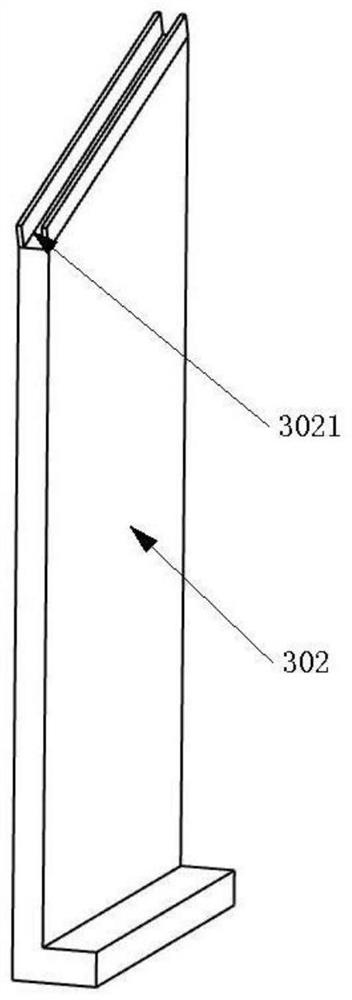

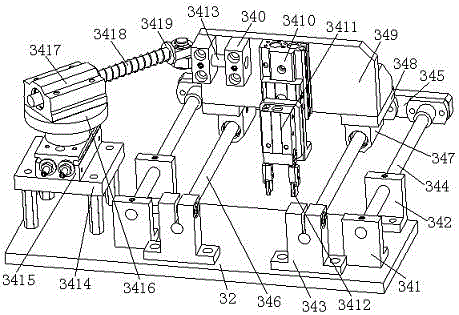

Unloading unit of brake pump sealing ring loading machine

InactiveCN106736394ANovel structureSimple and fast operationMetal working apparatusEngineeringMechanical engineering

The invention discloses an unloading unit of a brake pump sealing ring loading machine. The unloading unit of the brake pump sealing ring loading machine comprises a displacing guide plate; the upper plane of the displacing guide plate is fixed with an unloading connecting plate through a reinforcing rib; the upper plate of the unloading connecting plate is fixed with a double-travel cylinder with a downward piston rod; the piston rod of the double-travel cylinder penetrates through the unloading connecting plate to fix with an unloading lifting shaft mounting plate; an opening through groove is formed in one surface, towards the displacing guide plate, of the unloading lifting shaft mounting plate; longitudinal unloading lifting shafts are respectively fixed on two sides of the piston rod of the double-travel cylinder on the upper plane of the unloading lifting shaft mounting plate; the upper ends of the two unloading lifting shafts penetrate through the unloading connecting plate; and two longitudinal unloading bolts are inserted in the unloading connecting plate. Through the mode, the unloading unit of the brake pump sealing ring loading machine is simple and novel in structure and convenient to operate, realizes full-automatic operation in the unloading process, can continuously and automatically unload materials, and replaces manual workpiece unloading.

Owner:苏州迈邻物业管理有限公司

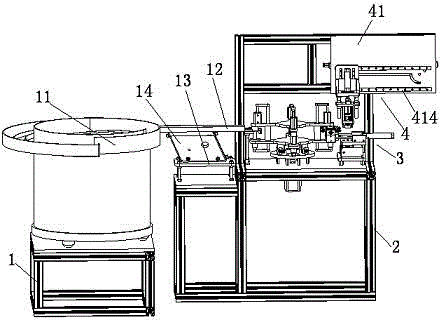

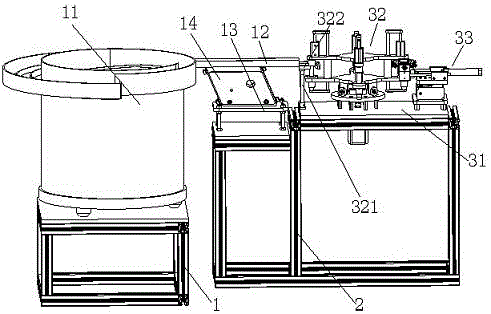

Interface detector providing convenience for picking and placing material

ActiveCN107826631AAvoid misalignmentImprove detection accuracyMeasurement devicesConveyor partsPower flowDistribution control

The invention relates to an interface detector providing convenience for picking and placing material. The interface detector comprises a frame, a power distribution control cabinet and a conveying device; the conveying device comprises a conveying seat; the conveying seat is provided with a conveying groove and a picking and placing groove; the conveying seat is also provided with a feeding device; the frame is provided with a current detecting device, a camera detecting device and a discharging mechanical arm; a carrier comprises a carrier main body which is matched with the conveying grooveand the picking and placing groove; the upper part of the carrier main body is provided with a fixed material carrying block which is matched with a product main body; a clamping movable block is arranged at the internal lower part of the carrier main body; the front end of the clamping movable block is provided with a reset spring hole and is matched with a clamping reset spring; the clamping movable block is provided with two clamping movable grooves which are inclined inwards; each clamping movable groove is matched with a clamping movable rod; and the upper part of each clamping movable rod is provided with a clamping block. By adopting the conveying device and the carrier which are matched with each other, the interface detector provided by the invention realizes continuous conveyingand detection of a product, prevents dislocation and detection errors generated in detection, improves the detection precision and provides convenience for picking and placing the product.

Owner:东莞市银天新能源有限公司

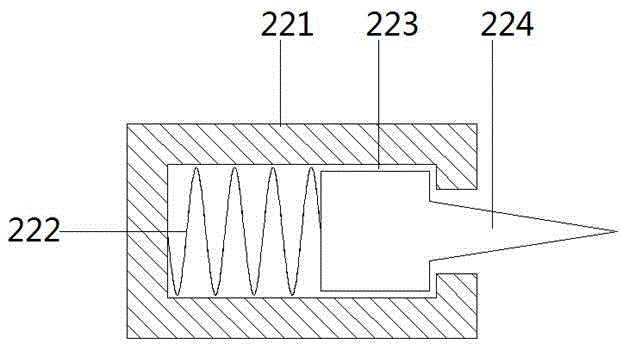

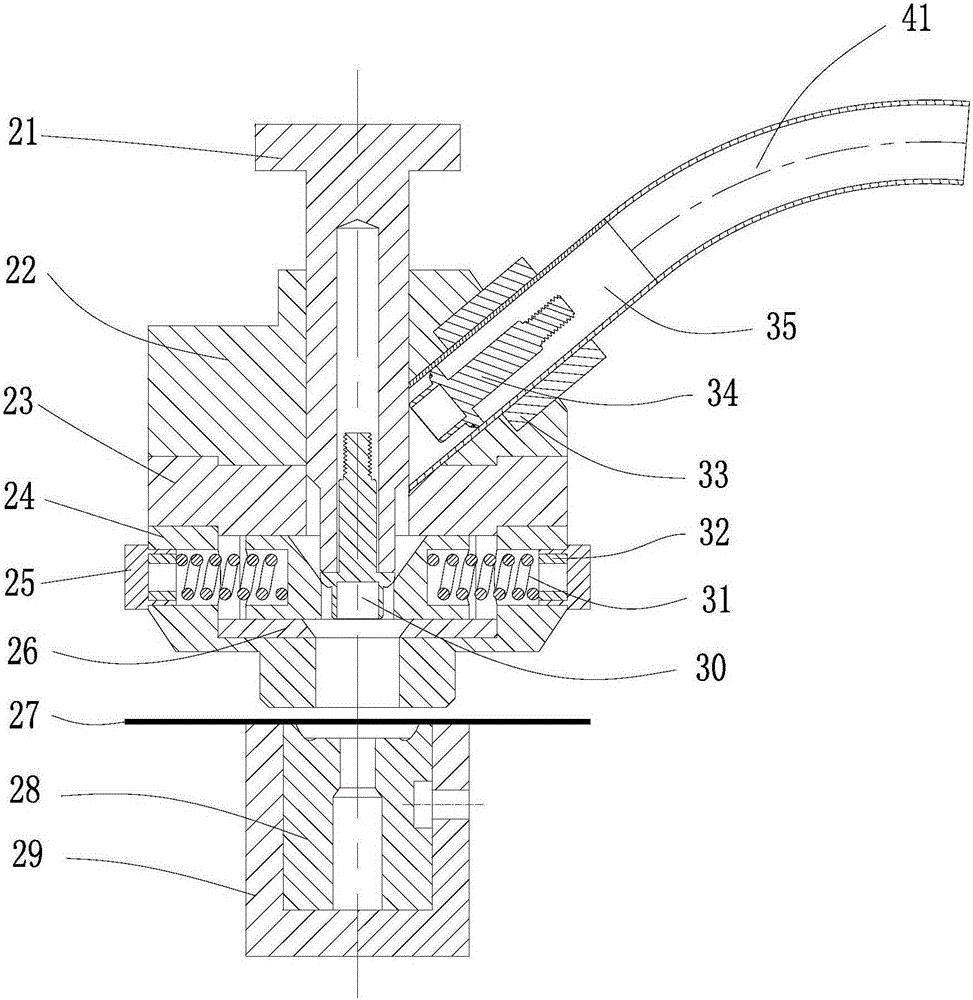

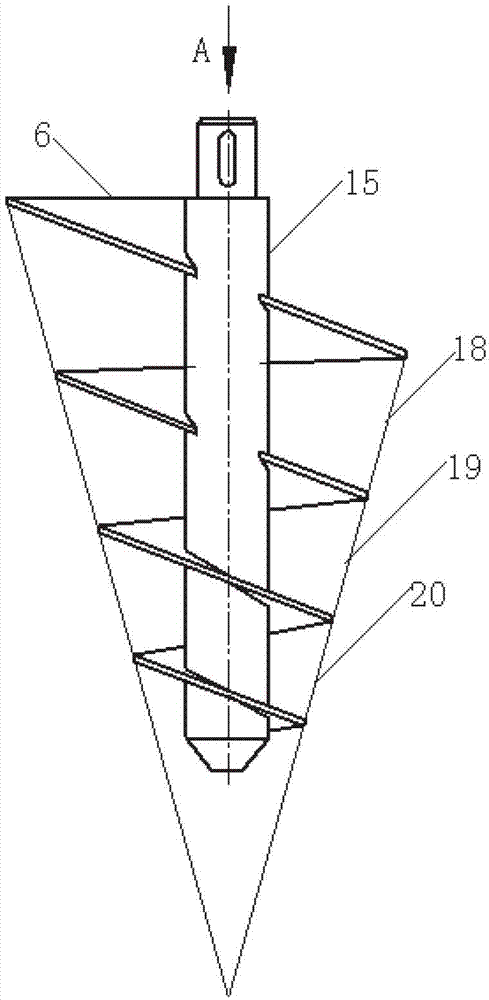

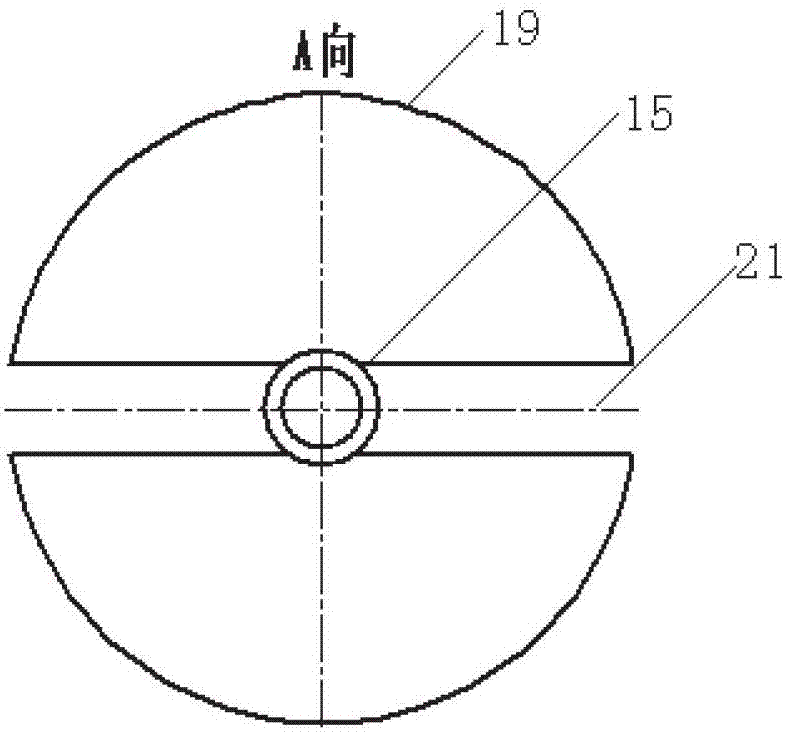

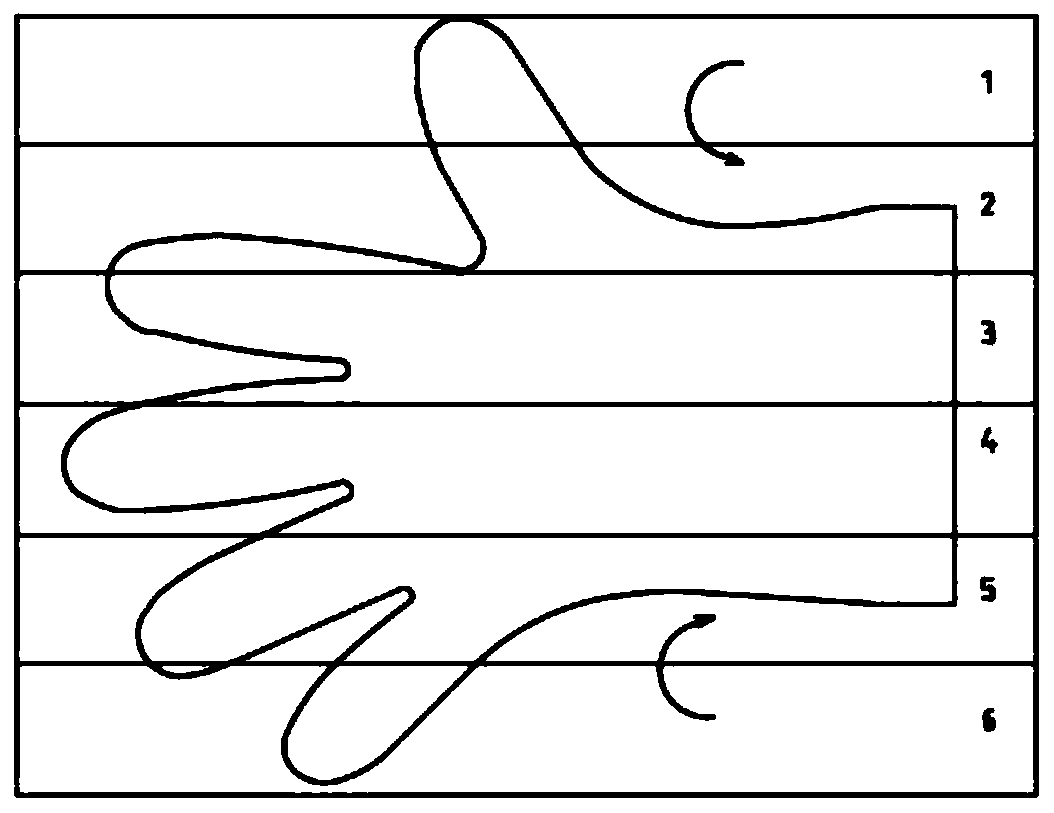

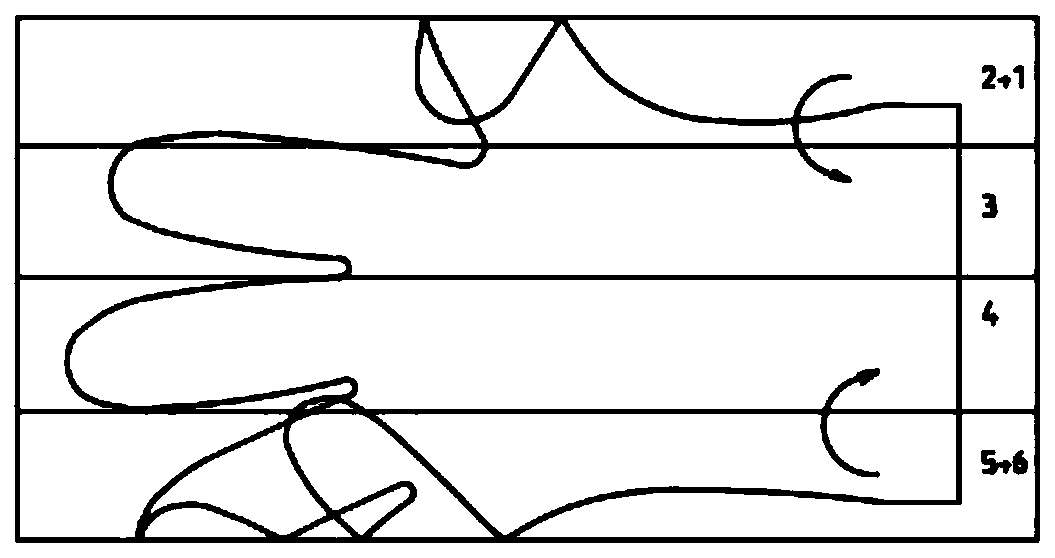

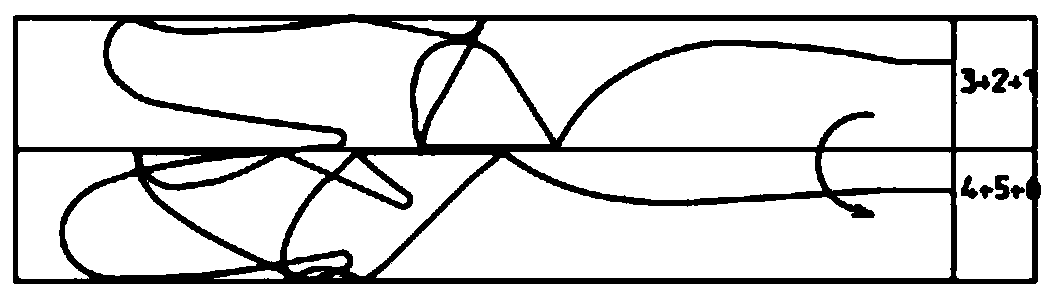

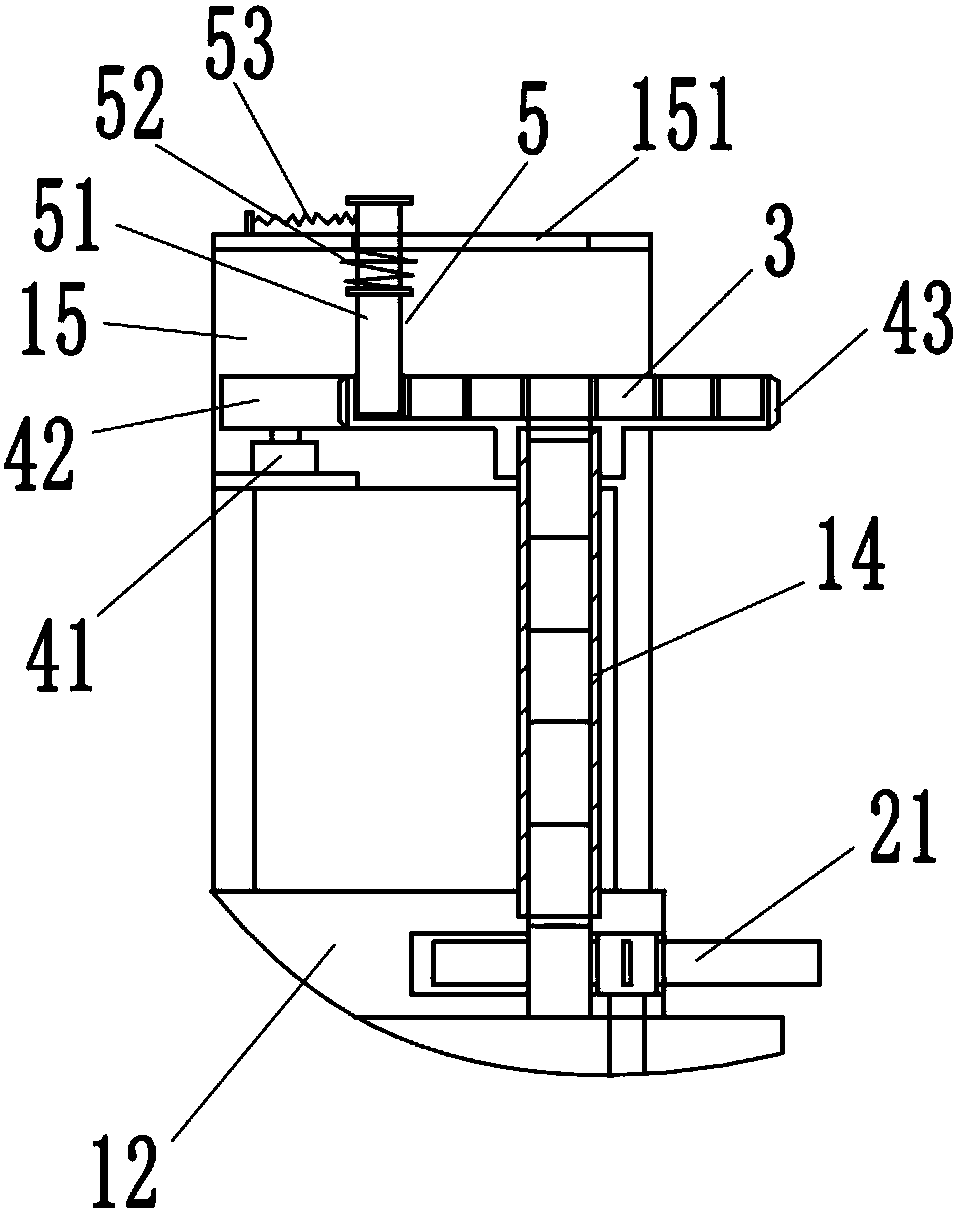

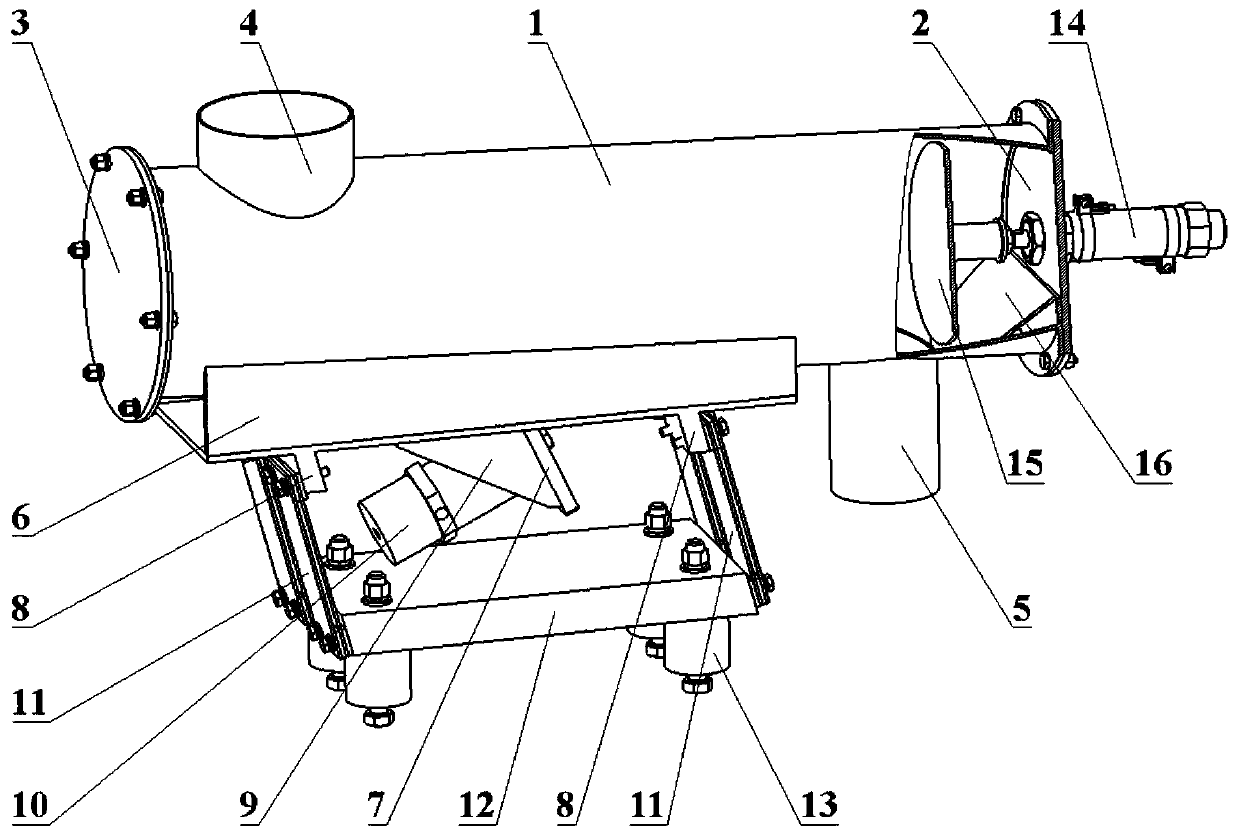

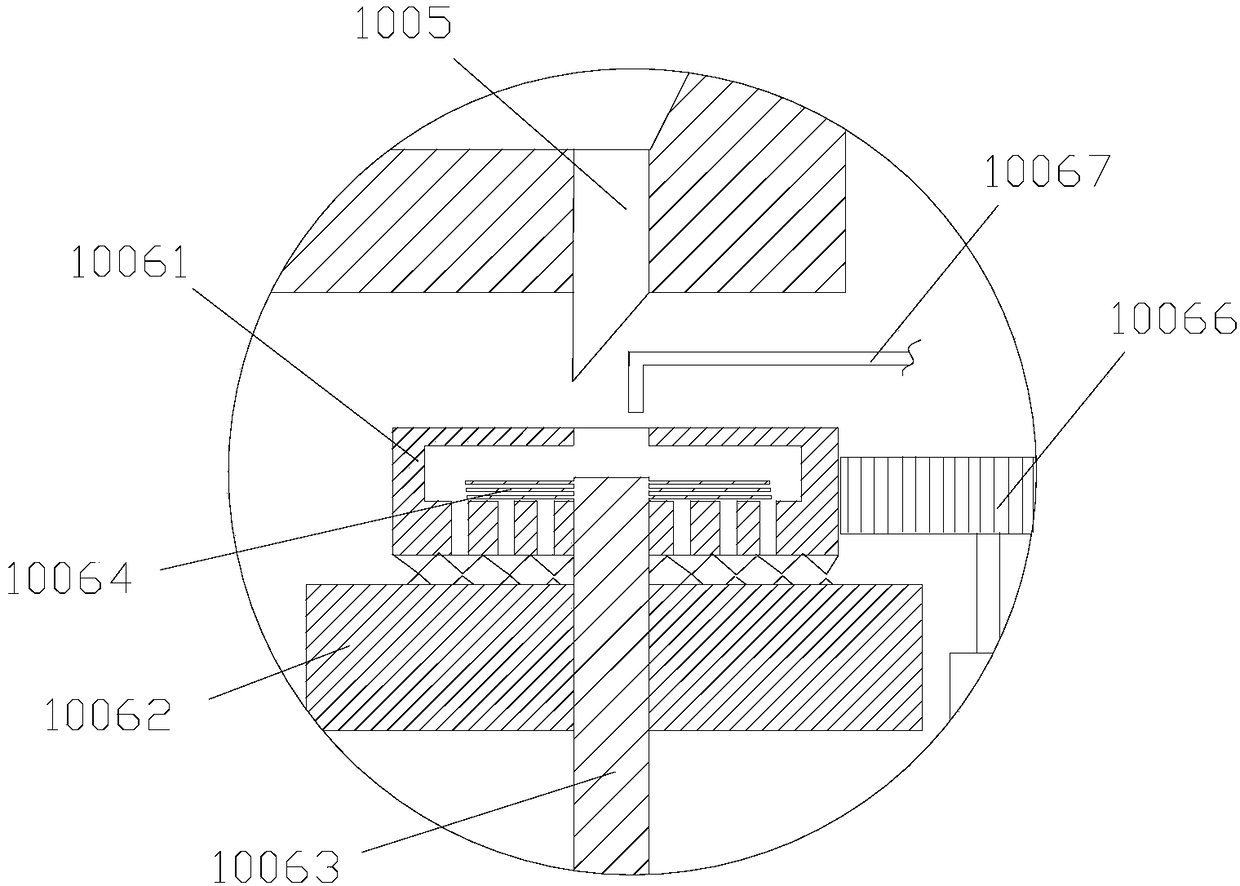

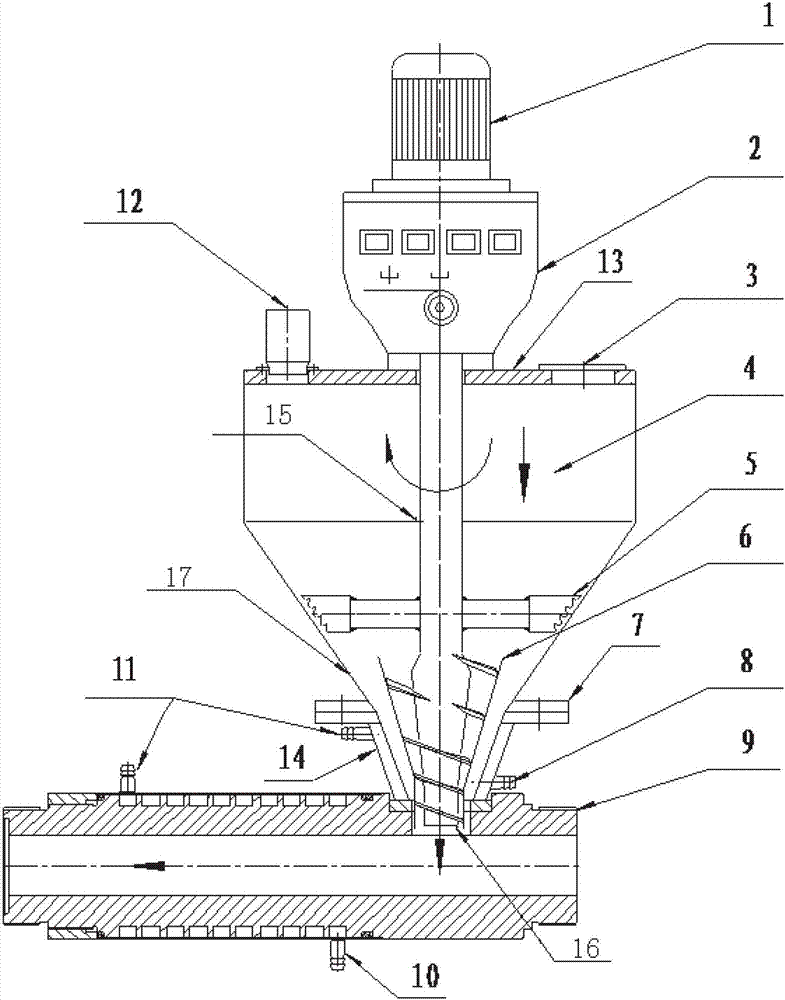

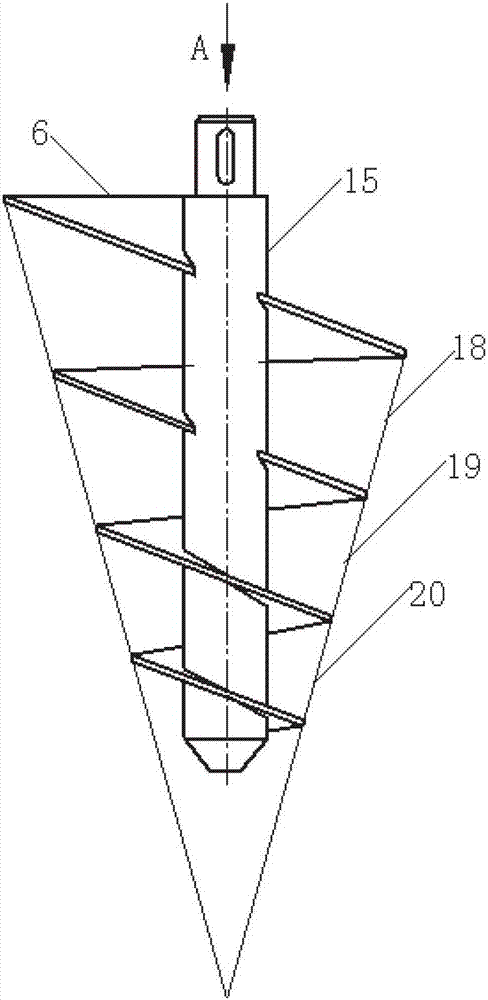

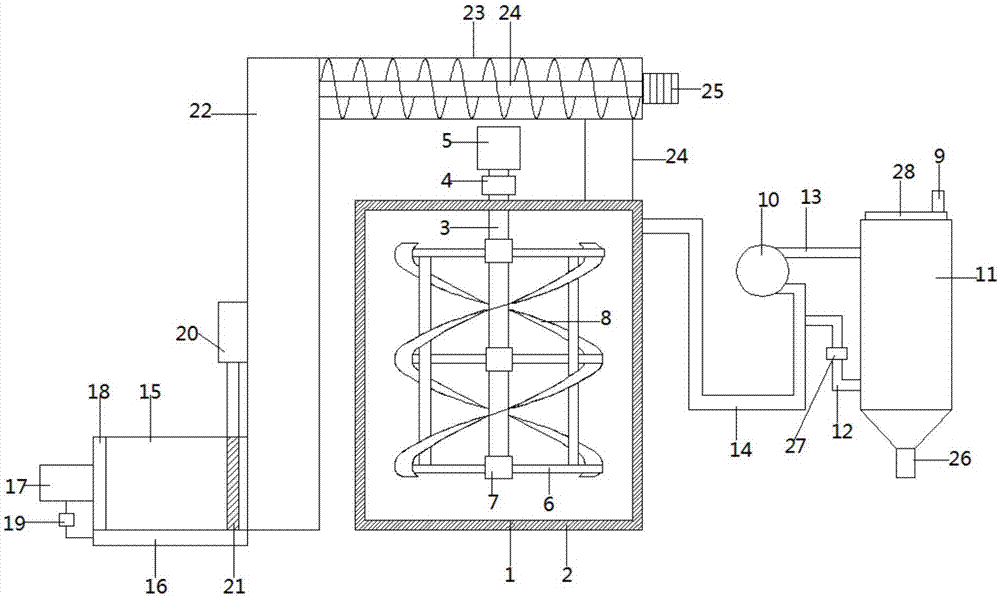

Mandatory continuous feeder for bulk material of mixed grease and glue

ActiveCN102964187ASmooth feedingContinuous automatic feedingExplosive working-up apparatusReducerEngineering

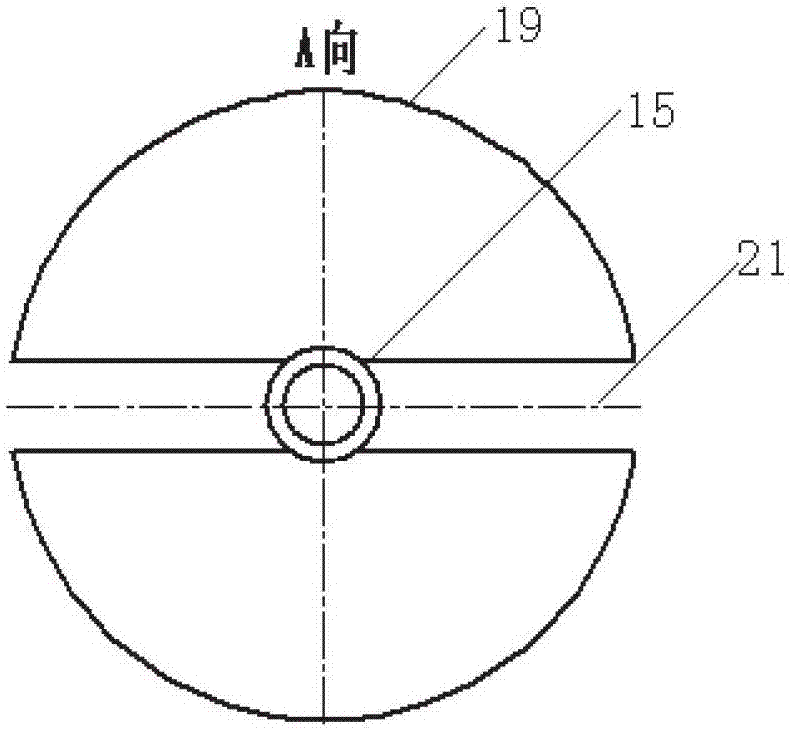

The invention provides a mandatory continuous feeder for a bulk material of mixed grease and glue. The mandatory continuous feeder comprises a radially communicated feeding container and a reducer driven by a motor. A feeding screw shaft (15) connected with a rotary shaft of the reducer is vertically connected with an anti-bridging agitating blade (5) fixedly and extends into a feed inlet (16) of a spiral forming machine (9) vertically. A spiral feeding and spinning feeder (6) consisting of upper, middle and lower layers of spiral feeding and spinning blades in different structures is arranged on the circumference of a rod body at a cone-shaped end of the feeding screw shaft. According to a middle layer screw blade (19) provided with a radial opened diffluent trough (21), one the one hand, materials are in a screw feeding state, and on the other hand, part of materials returns upward through the opening of the blade diffluent trough so as to exhaust and divide the materials. The lower layer screw blade feeds the materials to the feed inlet of a screw press continuously. The mandatory continuous feeder for the bulk material of mixed grease and glue provided by the invention is safe, feeds materials to the screw press stably, does not clot and block, and feeds uniformly. The quality stability in the forming process of a mixed grease blasting explosive is improved.

Owner:LUZHOU NORTH CHEM IND

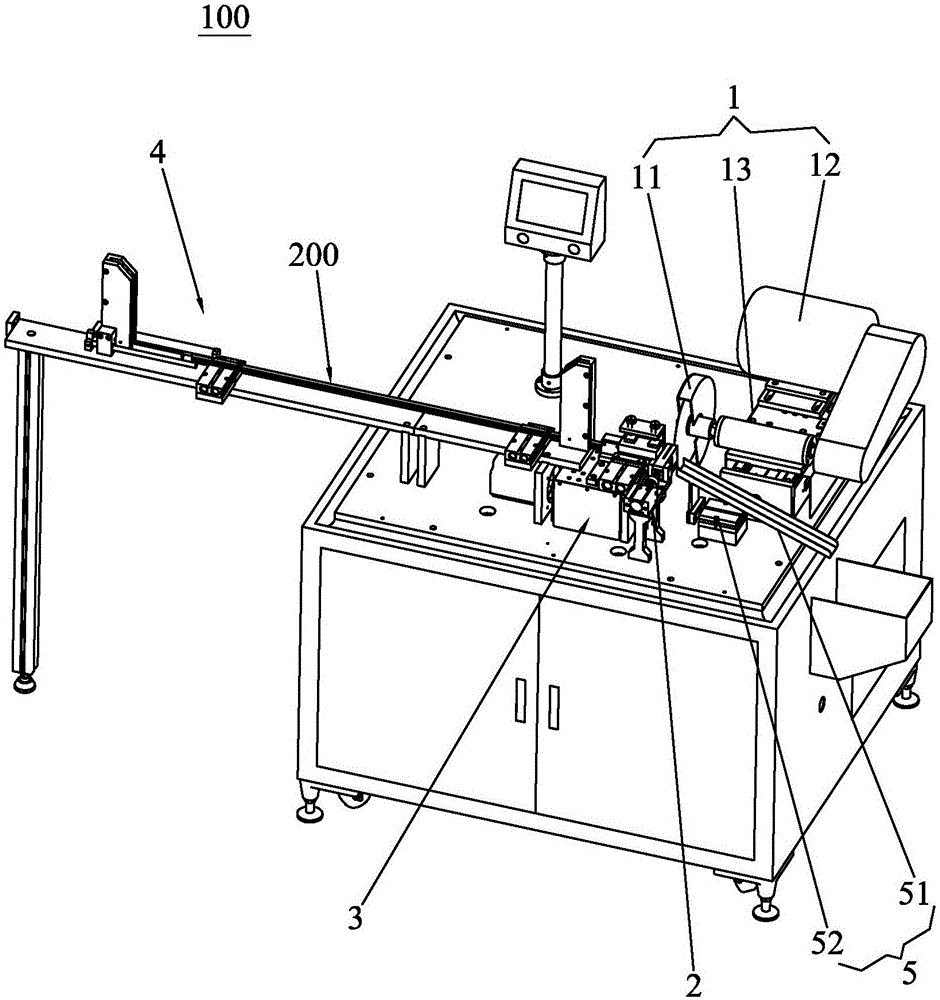

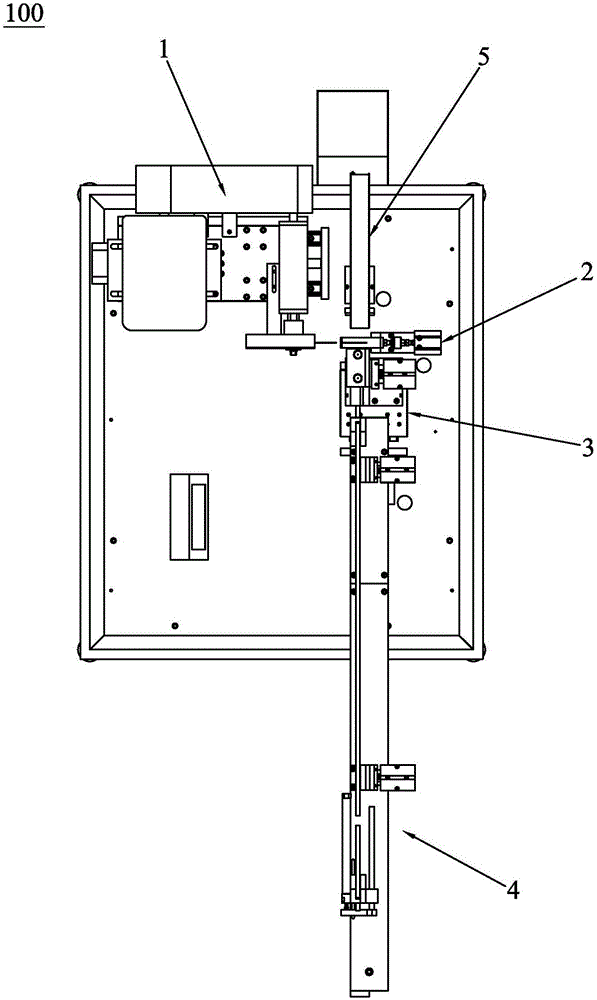

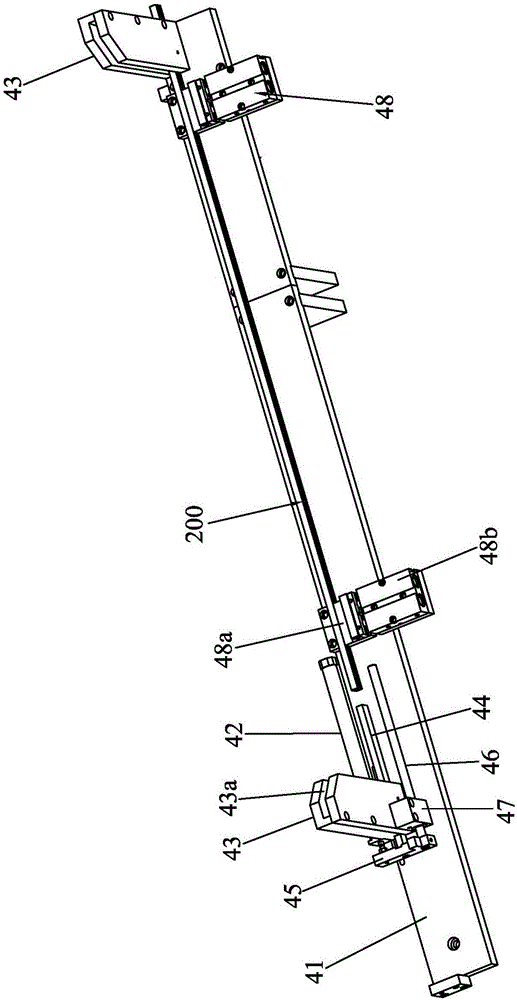

Automatic pipe feeding device and automatic pipe cutter

InactiveCN106735516AContinuous automatic feedingNo manual operation requiredMetal-working feeding devicesTube shearing machinesEngineeringIndustrial engineering

The invention discloses an automatic pipe feeding device. The automatic pipe feeding device comprises a feeding bracket, a pushing cylinder and a pair of limiting components. Two limiting components are fixed on the feeding bracket. A containing groove is installed in the vertical direction of each limiting component. The openings of the containing grooves of two limiting components are installed oppositely. Two ends of the pipe are contained in the containing groove and the pipe is superposed in the vertical direction. The pushing cylinder is fixed on the feeding bracket and the output end is protruded into the lower end of one limiting component and pushes the pipe below the limiting component, so the pipe below the limiting component is sent out from the lower end of the other limiting component. The automatic pipe feeding device does not need to be operated manually, the feeding process is automatically executed, and the production efficiency is effectively improved. In addition, the invention further discloses an automatic pipe cutter.

Owner:东莞沁智智能装备有限公司

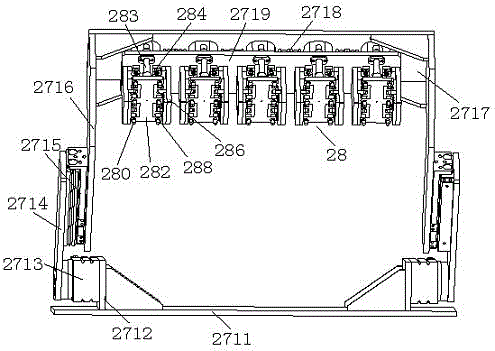

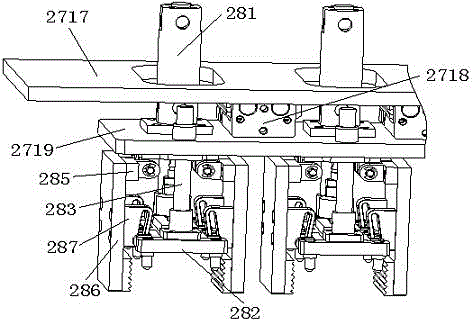

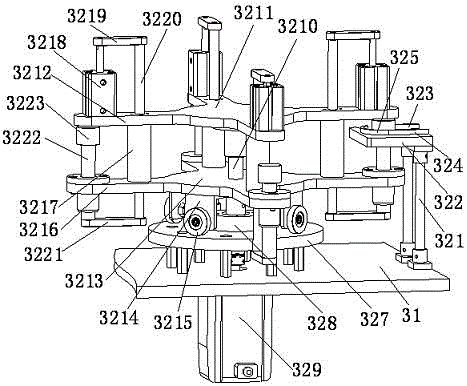

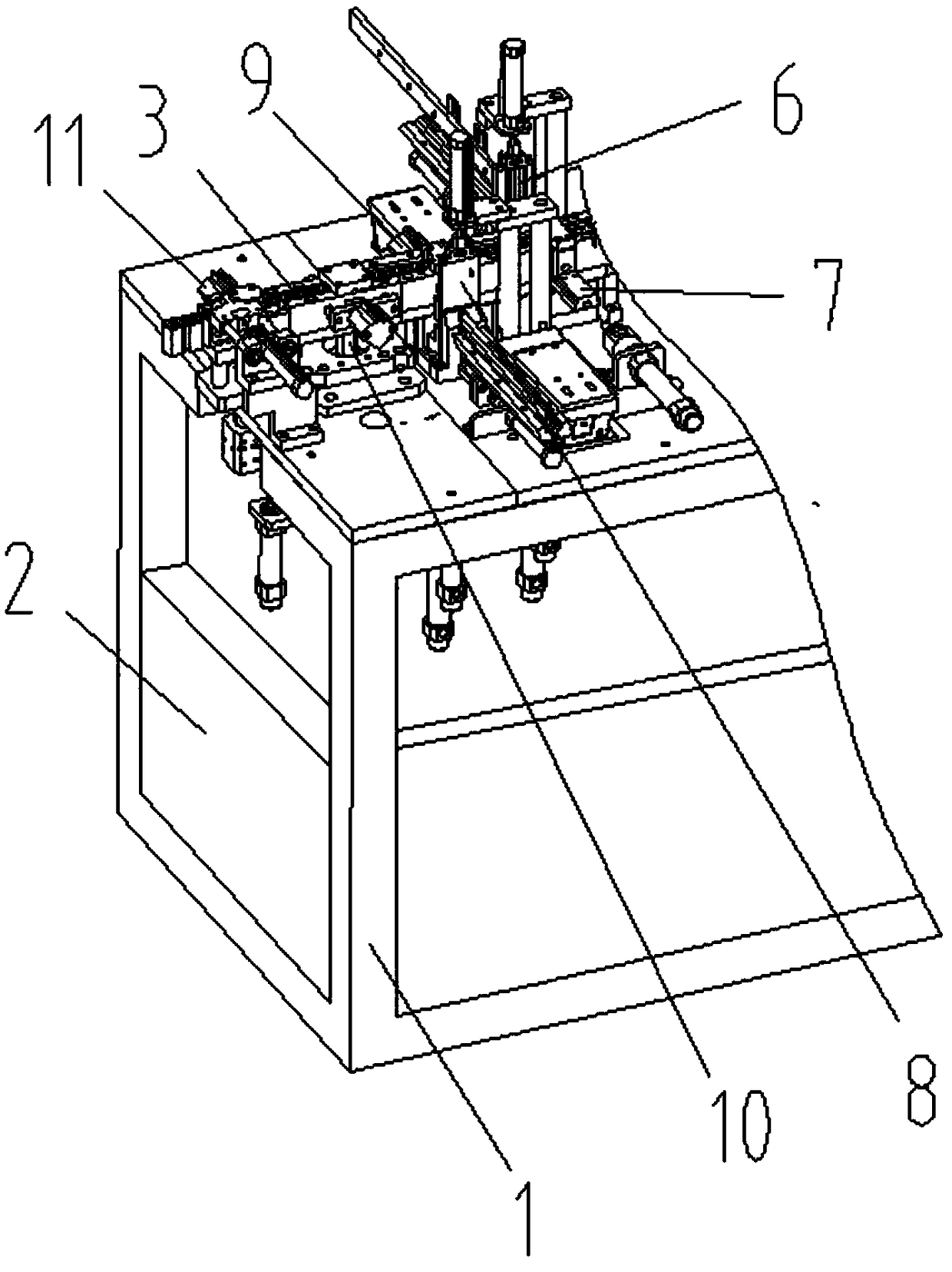

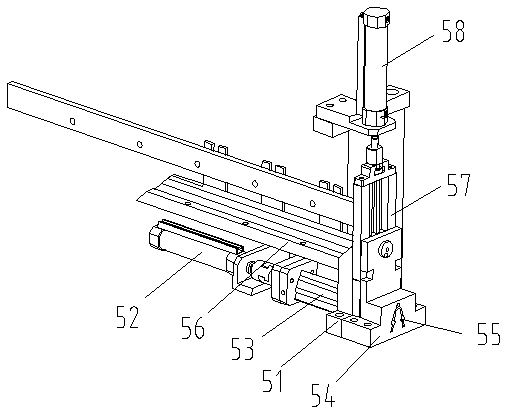

Feeding mechanism of brake pump sealing ring feeding machine

InactiveCN106808179ANovel structureSimple and fast operationMetal working apparatusEngineeringMechanical engineering

The invention discloses a feeding mechanism of a brake pump seal ring feeder. The brake pump seal ring feeder includes a vibrating material pan mounting frame and a frame installed on the ground in sequence, and a vibrating material pan mounting frame on the vibrating material pan mounting frame. The material tray mounting plate, the vibrating material plate is fixed on the upper plane of the vibrating material plate mounting plate, the sealing ring is placed inside the vibrating material plate, the discharge port of the vibrating material plate is equipped with a conveying trough, and the frame is fixed below the conveying trough. Linear vibrator mounting plate, the upper plane of the linear vibrator mounting plate is fixed with a linear vibrator through the linear vibrator mounting seat, the linear vibrator is fixed to the lower plane of the conveying trough, and the frame is fixed on the outside of the discharge port of the conveying trough in turn Limited mounting plate and loading mounting plate. Through the above method, the present invention has simple and novel structure, easy operation, fully automatic operation in the feeding process, instead of manual feeding, and continuous automatic feeding.

Owner:苏州迈邻物业管理有限公司

Glove folding and packaging device

PendingCN110723371AReasonable designEasy to usePackaging automatic controlIndividual articlesMechanical engineeringIndustrial engineering

Owner:袋王环保科技(上海)有限公司

Seeding apparatus for planting single-bud sugarcanes

Owner:SOUTH CHINA AGRI UNIV

Shaft sleeve feeding system

InactiveCN108436758AContinuous automatic feedingHigh degree of automationGrinding feedersEngineeringAutomation

The invention provides a shaft sleeve feeding system. The shaft sleeve feeding system comprises a portal base, a material shifting device, a material plate, a material plate driving device for drivingthe material plate to rotate, a material pushing device, a movable clamping base and a movement driving mechanism for driving the movable clamping base to move. A pair of side plates is arranged on the top board of the portal base. A slideway is formed between the pair of side plates. A discharging pipe is arranged on the upper portion of the slideway. A window penetrating through the upper end face and the lower end face of the top board is arranged on the top board. A material shifting wheel of the material shifting device is pivoted to the top board and can push shaft sleeves to slide along the slideway when rotating. The material plate is movably arranged at the top end of the discharging pipe in a sleeving mode. The shaft sleeves are enabled by the material pushing device to enter the discharging pipe through a center hole of the material plate. The movable clamping base is used for clamping and fixing the shaft sleeves sliding out of the slideway. The processed shaft sleeves canpass through the window to fall to a material receiving plate under the action of an overturning air cylinder. According to the shaft sleeve feeding system provided by the invention, continuous feeding can be achieved, the automation degree is high, and application is convenient.

Owner:林淑录

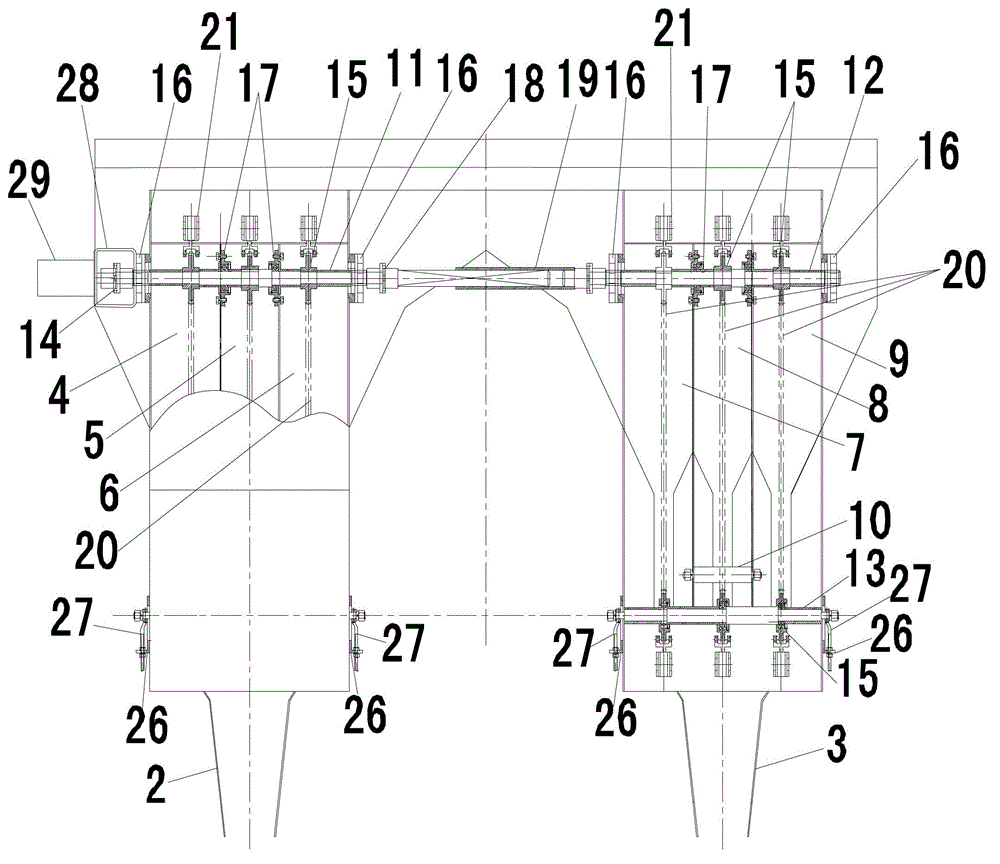

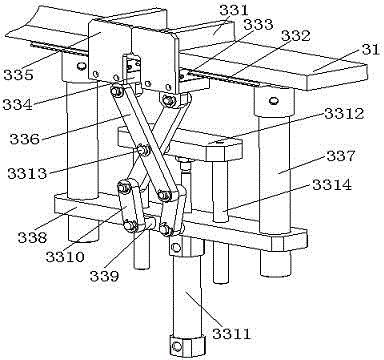

Feeding mechanism of brake pump shell feeding machine

InactiveCN106743521ANovel structureSimple and fast operationConveyor partsEngineeringMechanical engineering

The invention discloses a feeding mechanism of a brake pump shell feeding machine. The feeding mechanism comprises a rack mounted on the ground, wherein a discharging device and a feeding device are sequentially mounted on the rack; the discharging device conveys a shell to the feeding device, and the feeding device sends the shell away; the discharging device comprises a discharging unit mounted on the rack, a positioning unit and a displacement unit; the positioning unit and the displacement unit are sequentially arranged on the rack and are positioned below the discharging unit; the positioning unit corresponds to the discharging unit; the discharging unit conveys the shell out; the positioning unit positions the shell; and the displacement unit sends the shell away. Through the manner, the feeding mechanism is simple and novel in structure and simple and convenient to operate, realizes full-automatic operation during the feeding process, can continuously realize automatic feeding, and replaces manual feeding of a workpiece.

Owner:苏州迈邻物业管理有限公司

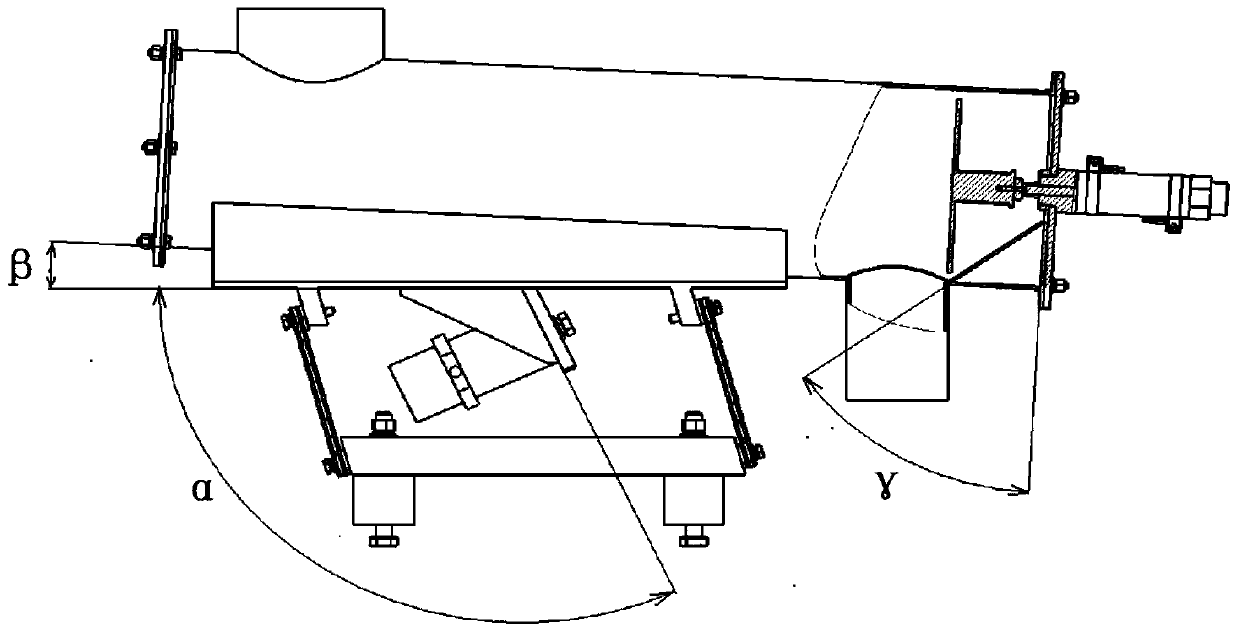

Pneumatic vibration material feeding device

InactiveCN111532685AMovement precisionPrecise automatic feedingControl devices for conveyorsJigging conveyorsControl systemMan machine

The invention relates to a pneumatic vibration material feeding device. The pneumatic vibration material feeding device comprises material feeding equipment, weighing equipment and a self control system, wherein the material feeding equipment, the weighing equipment and the self control system are connected through a control loop. According to preset self control program, set weight parameters, and signals transmitted and fed back by the weighing equipment in real time, a pneumatic vibrator and a precise material feeding assembly of the material feeding equipment are automatically started andstopped; the precise, continuous and quantitative automatic material feeding of powder materials in energetic material production is realized; the man-machine isolation is realized; the work intensityof employees is reduced; and the essential safety degree is improved.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

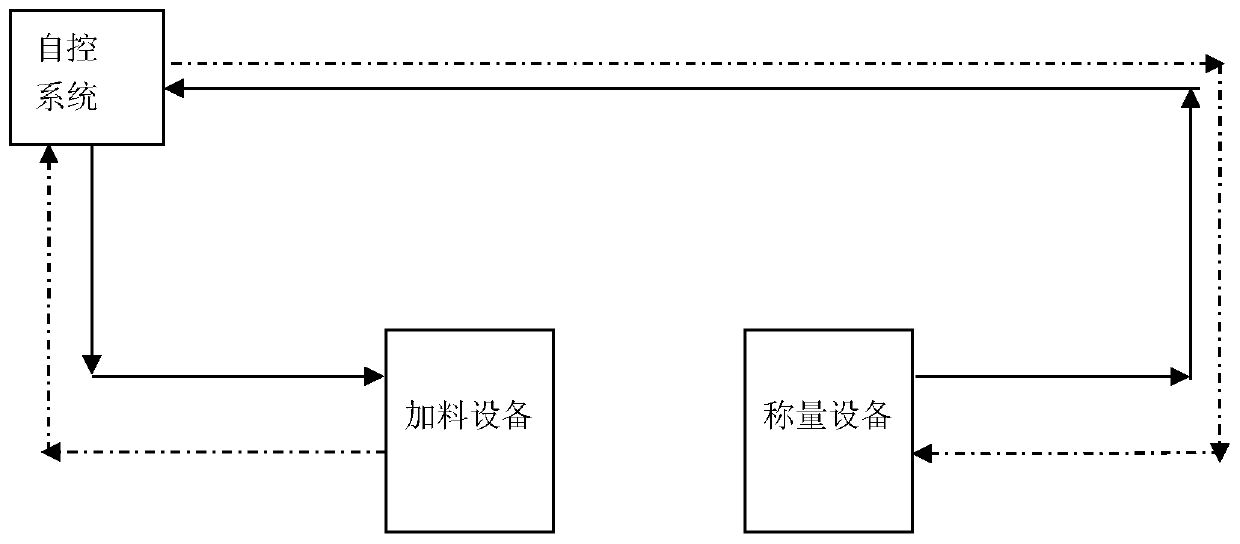

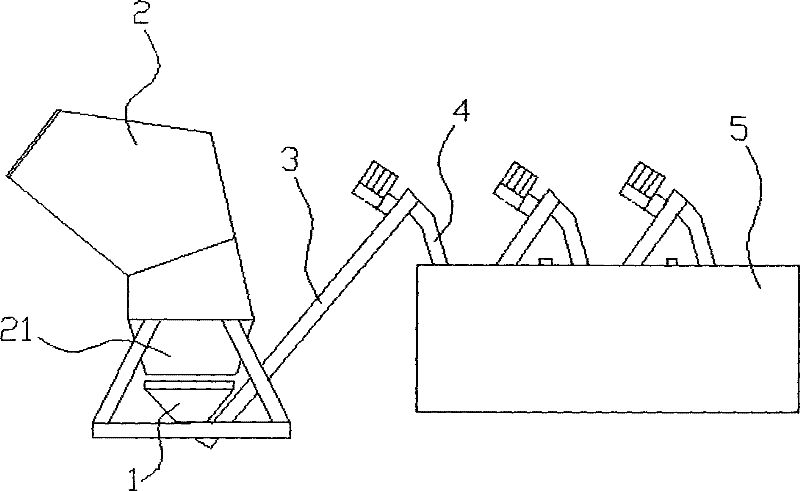

Plastic regenerating, crushing and cleaning integrated device

InactiveCN102672849ASimple structureReasonable designPlastic recyclingCleaning using liquidsEngineeringMechanical engineering

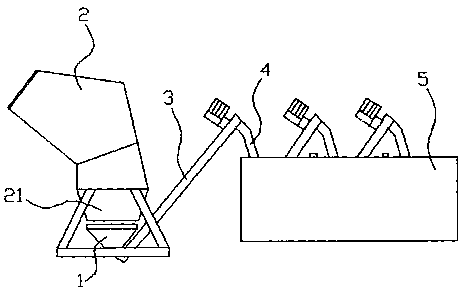

The invention discloses a plastic regenerating, crushing and cleaning integrated device, and relates to the technical field of plastic machines. The device comprises a plastic crushing machine and a cleaning box, and is characterized in that a spiral loading rod is obliquely arranged between the plastic crushing machine and the cleaning box; the upper end of the spiral loading rod is provided with a discharge hole, and the lower end of the spiral loading rod is connected with a receiving hopper; the receiving hopper is positioned below the discharging hole of the plastic crushing machine; and the discharge hole is extended into a cleaning barrel of the cleaning box. The device has a simple structure and is reasonable in design, and the plastic crushing machine is connected with the cleaning box of crushed plastics through the spiral loading rod, so that the crushed plastics can be directly conveyed into the cleaning box for cleaning; and therefore, a continuous automatic loading process can be realized, and the device is high in processing efficiency.

Owner:ANHUI JINZHENG PLASTIC

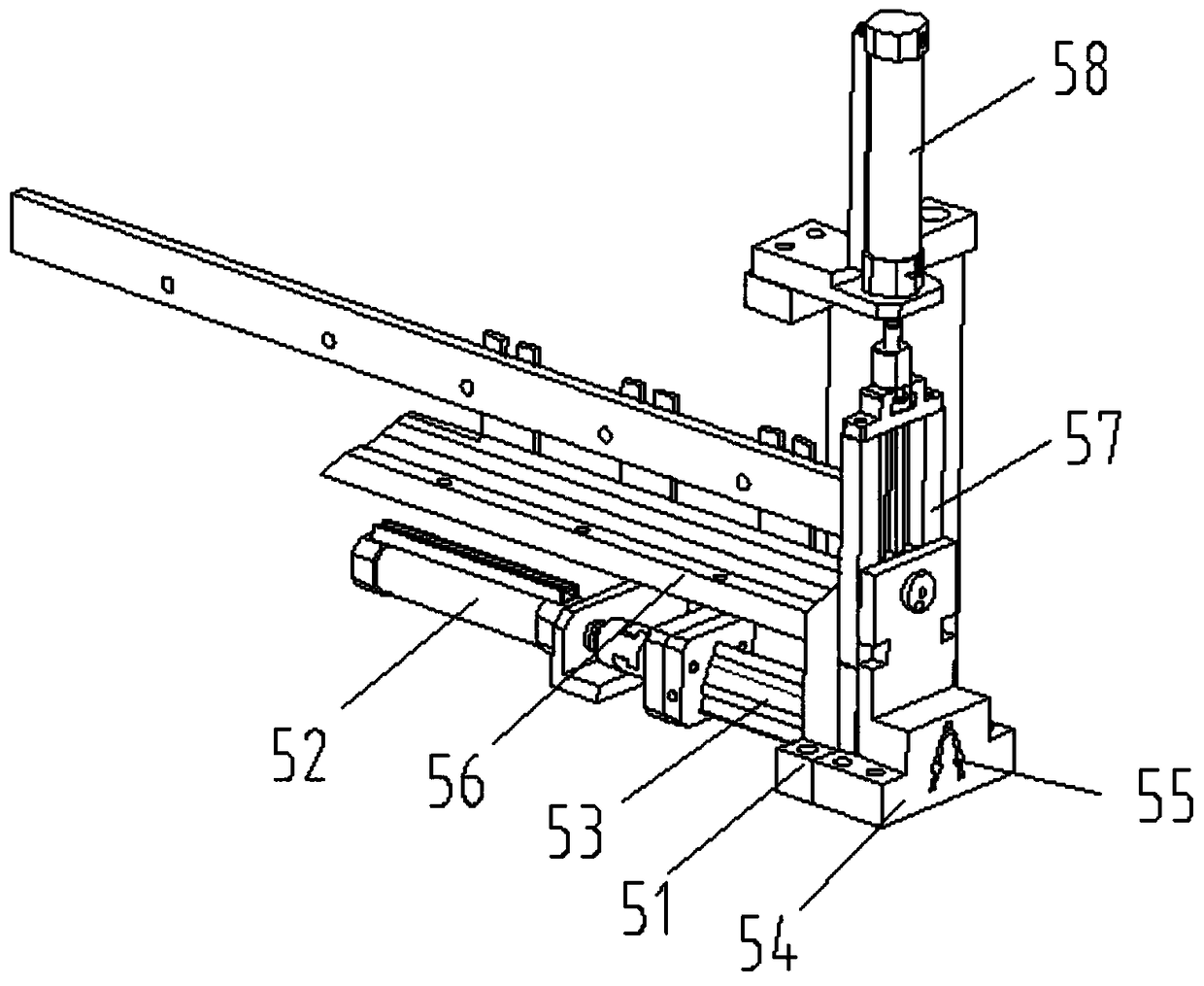

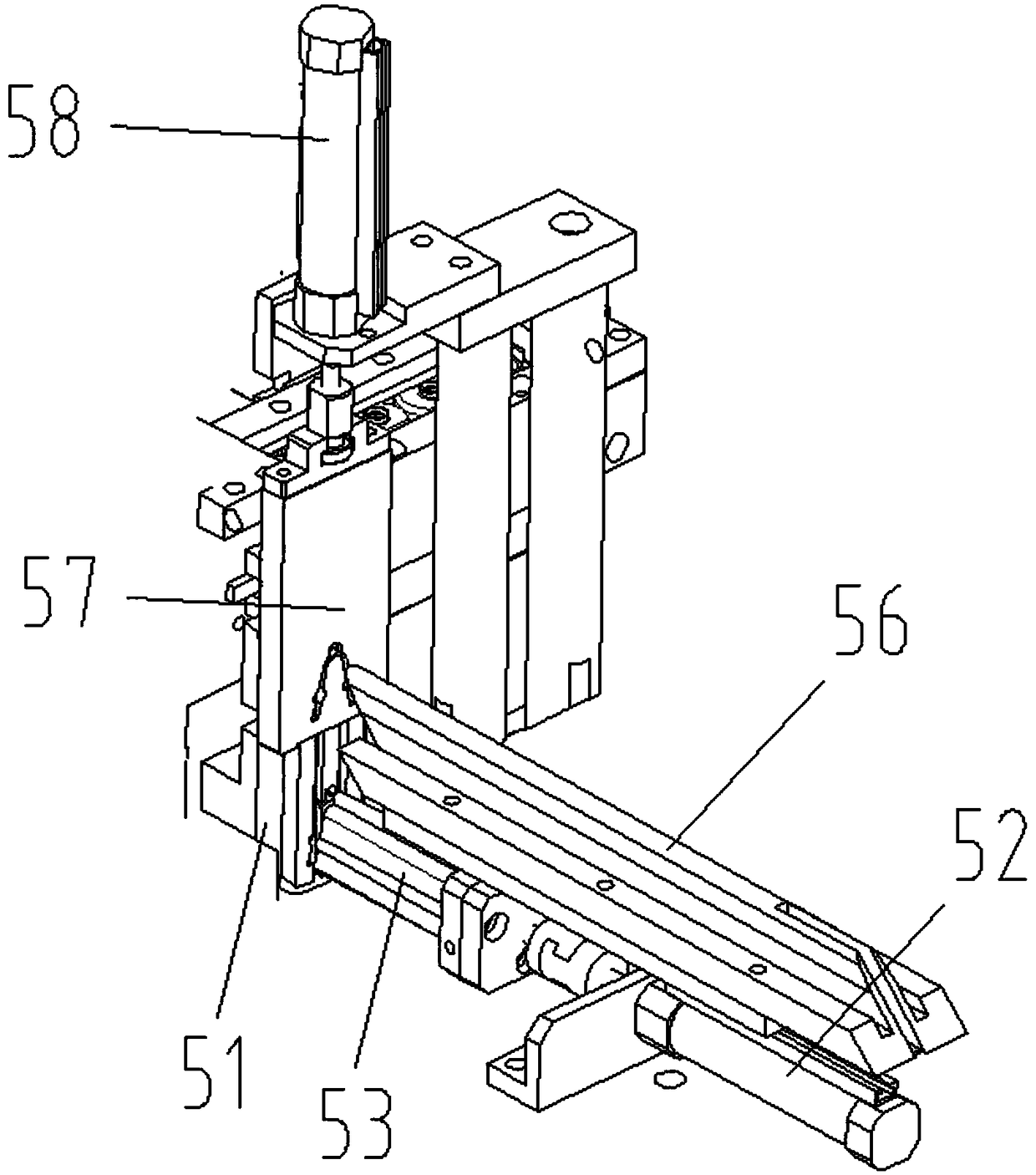

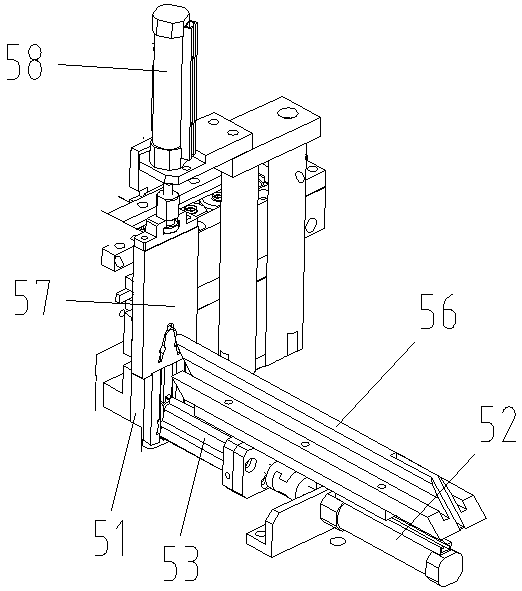

Feeding unit of brake pump shell feeding machine

InactiveCN106743587ANovel structureImplement the flip functionMetal working apparatusConveyor partsRotary stage

The invention discloses a feeding unit of a brake pump shell feeding machine. The feeding unit comprises a feeding mounting plate, wherein two ends of the upper plane of the feeding mounting plate are fixed with feeding rotary air cylinder mounting plates perpendicular to the two ends through reinforcing ribs; the two feeding rotary air cylinder mounting plates are positioned on the same horizontal line; transverse feeding rotary air cylinders are fixed on outer side faces of the two feeding rotary air cylinder mounting plates; rotary tables of the two feeding rotary air cylinders are outwards; a feeding sliding table air cylinder mounting plate is fixed on a rotary table of each of the two feeding rotary air cylinders; and feeding sliding table air cylinders are fixed on opposite inner lateral faces of the two feeding sliding table air cylinder mounting plates. Through the manner, the feeding unit is simple and novel in structure, can realize the overturning function, realizes full-automatic operation during the feeding process, can continuously realize automatic feeding, and replaces manual feeding of a workpiece.

Owner:苏州迈邻物业管理有限公司

Plastic regenerative breaking and cleaning all-in-one device

InactiveCN111070491ASimple structureReasonable designPlastic recyclingMechanical material recoveryMechanical engineeringIndustrial engineering

The invention discloses a plastic regenerative breaking and cleaning all-in-one device, and relates to the technical field of plastic machines. The device comprises a plastic breaker and a cleaning box and is characterized in that a spiral loading rod is mounted between the plastic breaker and the cleaning box, and is inclined, an outlet is formed in the upper end of the spiral loading rod, the lower end of the spiral loading rod is connected with a receiving hopper, the receiving hopper is located below a discharging opening of the plastic breaker, and the outlet stretches into a cleaning cylinder of the cleaning box. The plastic regenerative breaking and cleaning all-in-one device is simple in structure, and reasonable in design, the plastic breaker and the cleaning box for the broken plastic are connected through the spiral loading rod, the broken plastic can be directly conveyed into the cleaning box to be cleaned, continuous automatic loading can be achieved, and machining efficiency is high.

Owner:湖北奥斯龙科技有限公司

Tea cup production line, and method for producing tea cup by using production line

The invention discloses a tea cup production line sequentially comprising a blank making mechanism, a glazing mechanism, a glost kiln and an auxiliary glazing device from front to back according to aprocess flow. The blank making mechanism comprises a blank making table, a blank making rotary shaft and a blank making rotary plate; a circle of guiding chute is further formed in the blank making table; a grinding device is arranged under a discharge hole of the guiding chute; the glazing mechanism comprises a main rotary base and a hairbrush; a cup blank to be glazed is arranged on the main rotary base; the main rotary base rotates to drive the cup blank to be glazed to rotate; a bristle end of the hairbrush can be in abut-joint to the outer surface of the cup blank to be glazed; and the auxiliary glazing device comprises an auxiliary rotary base, a black glaze cup model, an auxiliary contact rod, an auxiliary batch type lifting mechanism, an auxiliary elastic device, an auxiliary batchtype pushing mechanism and an auxiliary clamping device. The invention further discloses a method for producing a tea cup by using the tea cup production line. The tea cup production line provided bythe invention has the advantages of high pug utilization rate, uniformity in glazing, and good glazing effect.

Owner:福建省东丰阁文化发展有限公司

A mechanical processing automatic conveying device

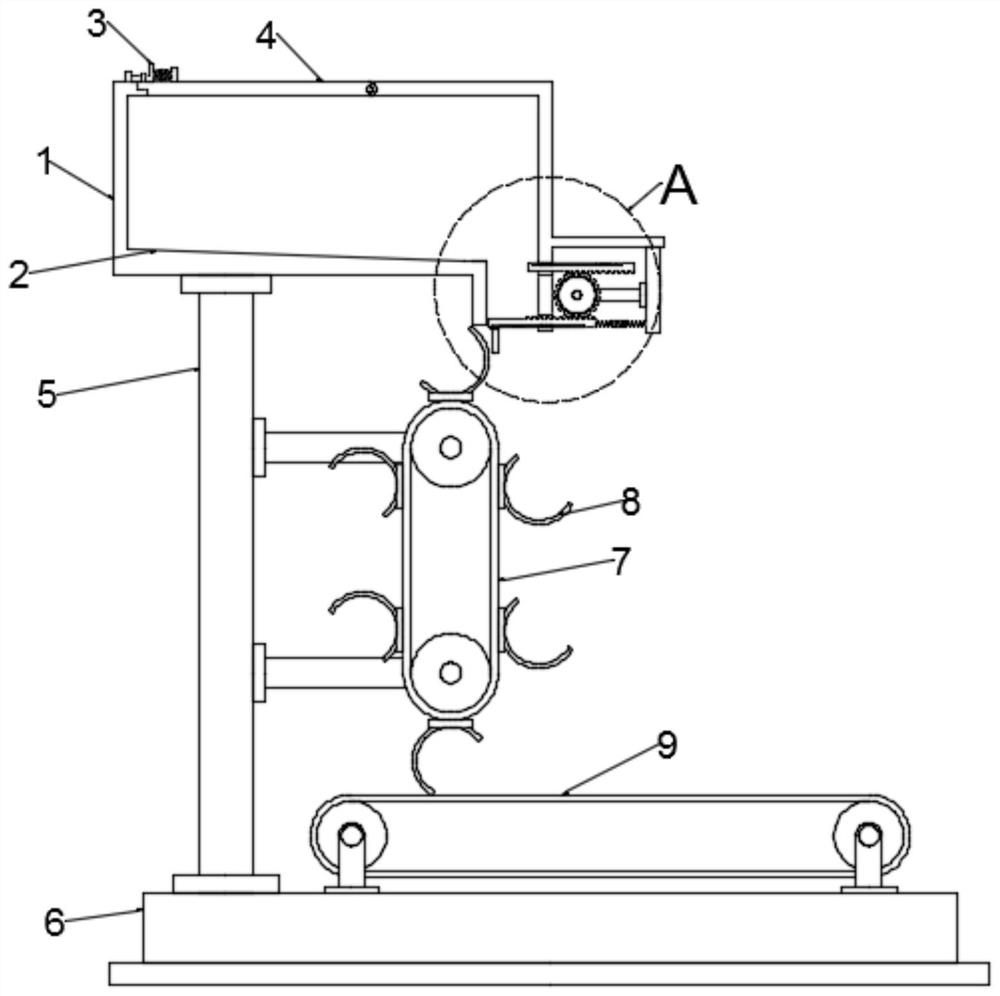

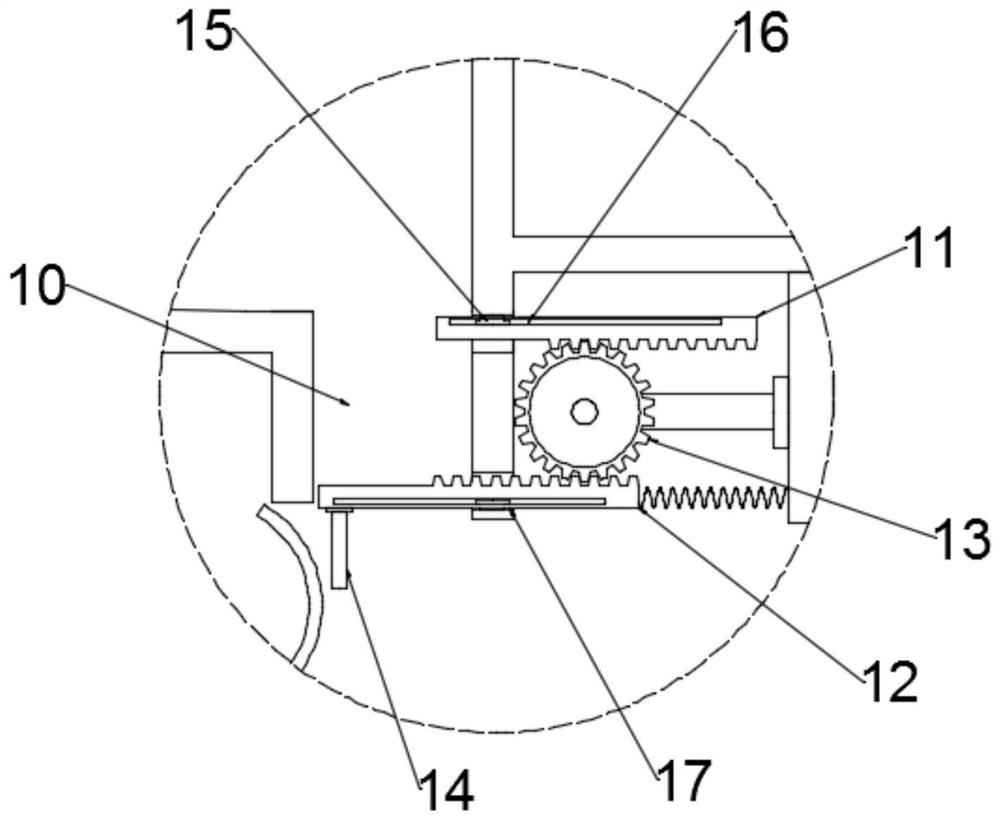

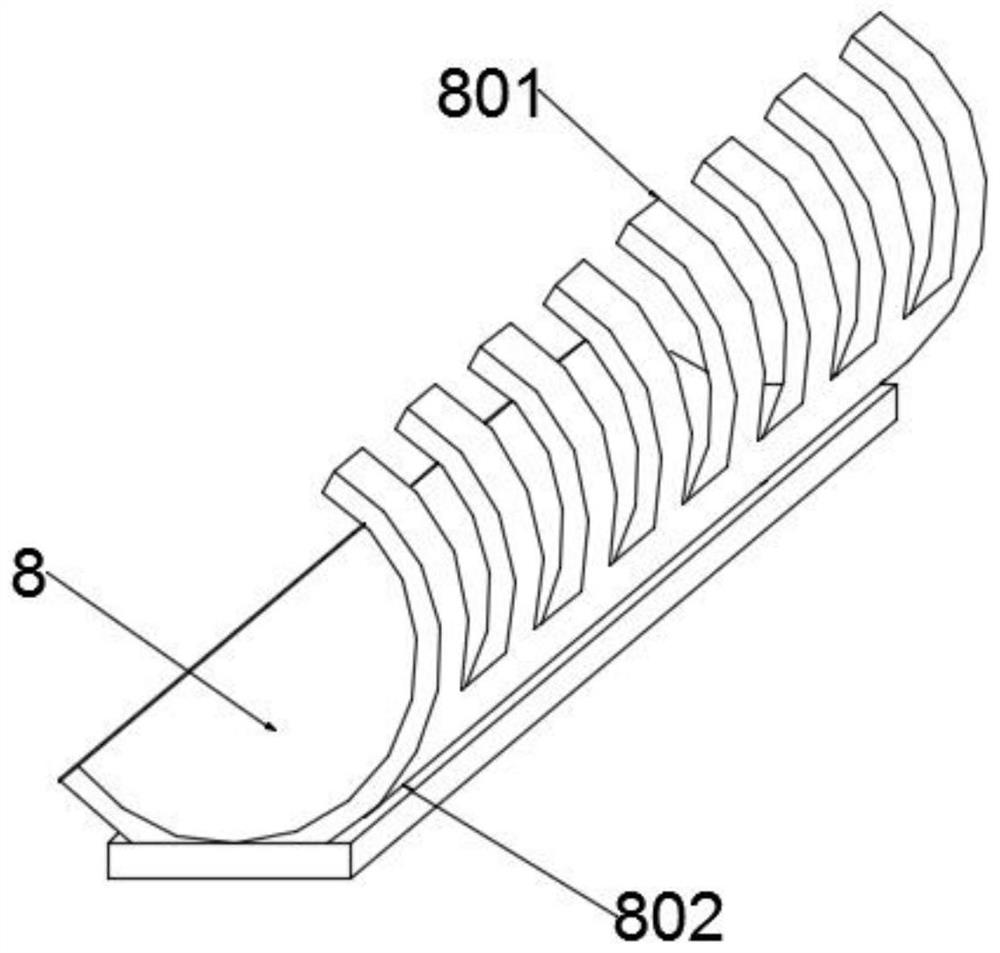

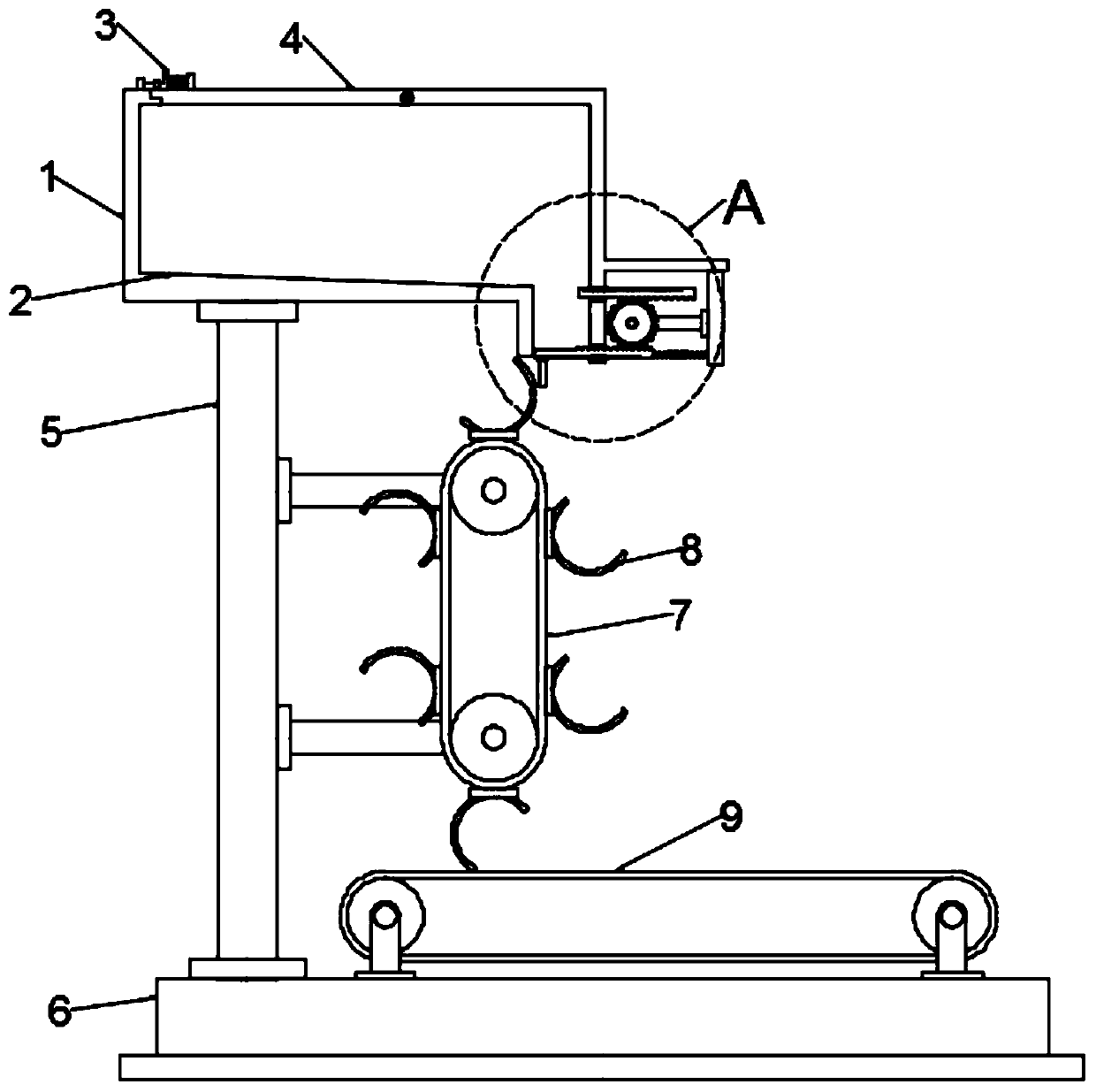

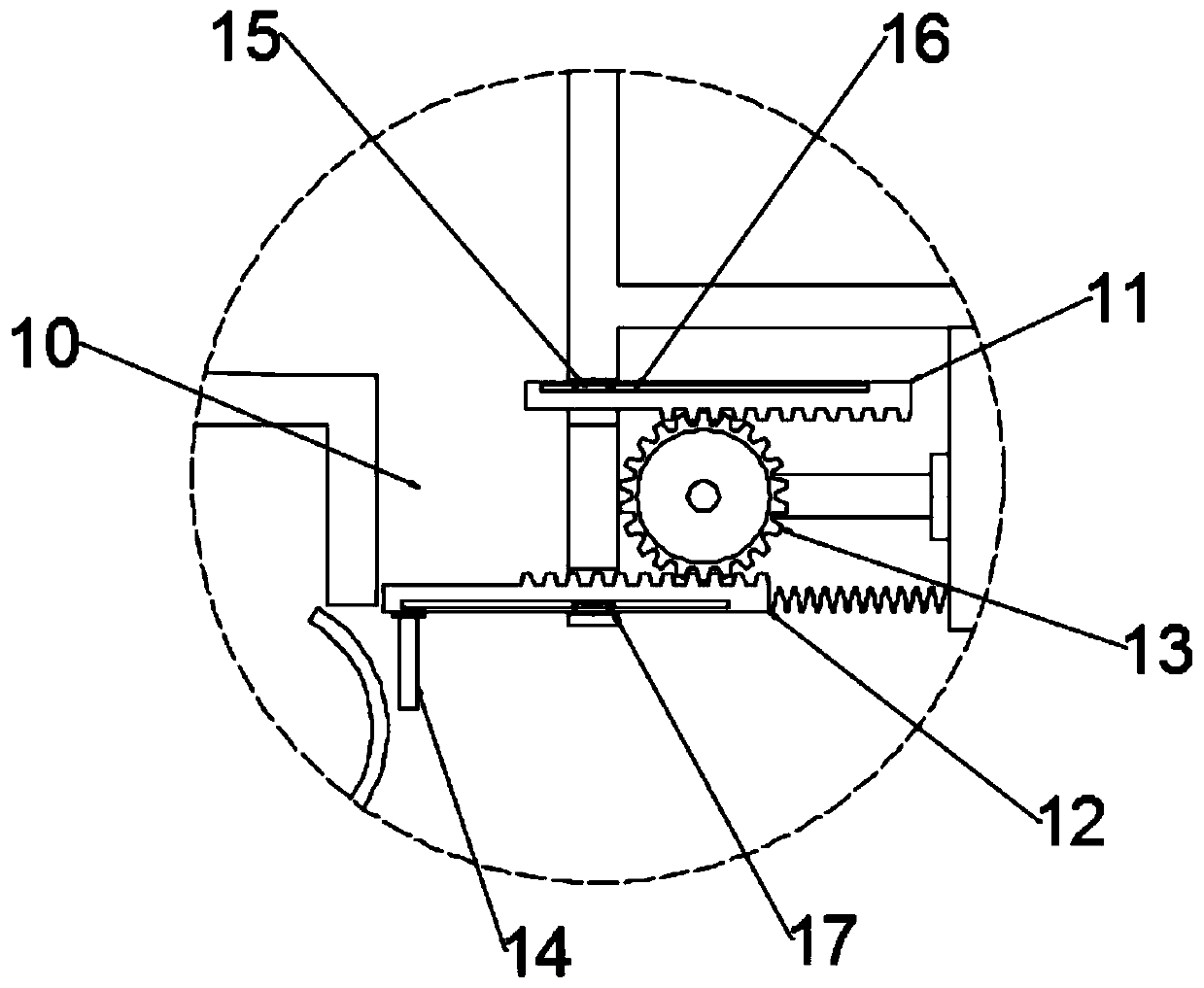

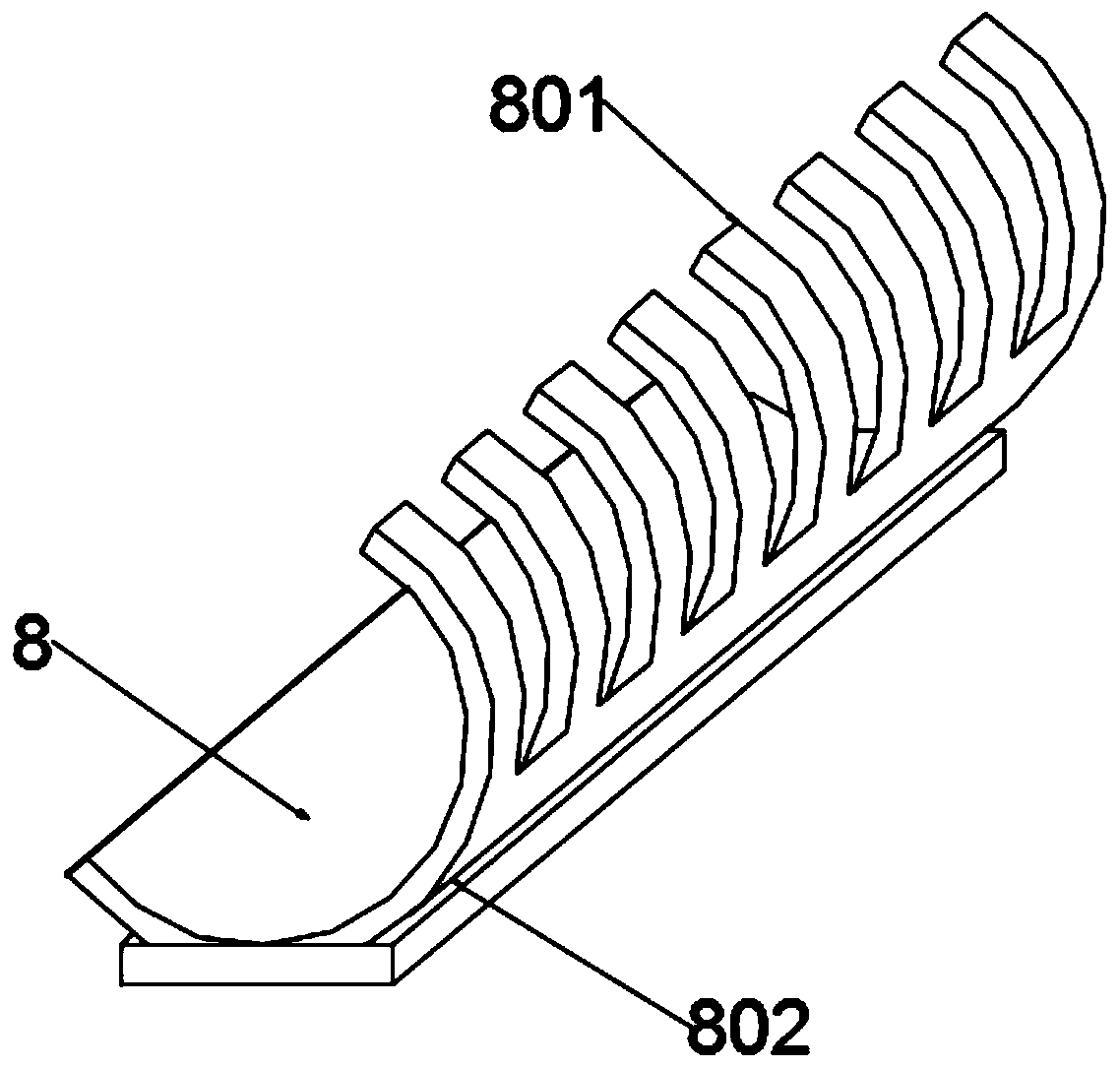

The invention relates to the correlation technical field of machining, in particular to a machining automatic conveying device. The machining automatic conveying device comprises a containing cavity.The containing cavity is fixed to a base through a support, a buffer cavity is formed in one side of the lower end of the containing cavity, an upper rack plate and a lower rack plate are arranged atthe upper end and the lower end of the buffer cavity, the motion directions of the upper rack plate and the lower rack plate are opposite, a conveying chain assembly mounted on the support is arrangedbelow the containing cavity, and multiple arc-shaped jaws are mounted on the conveying chain assembly at equal intervals. The design is novel, when the arranged arc-shaped jaws move to the upper endof the conveying chain assembly, the arc-shaped jaws abut against a drive plate fixed to the lower rack plate, when the arc-shaped jaws continuously move, the drive plate drives the lower rack plate to be opened, a columnar part falls into the arc-shaped jaws, under the blocking effect of the upper rack plate, the other columnar parts are prevented from falling out, thus, continuous automatic feeding is achieved, and the automation degree is high.

Owner:XIAN UNIV OF POSTS & TELECOMM

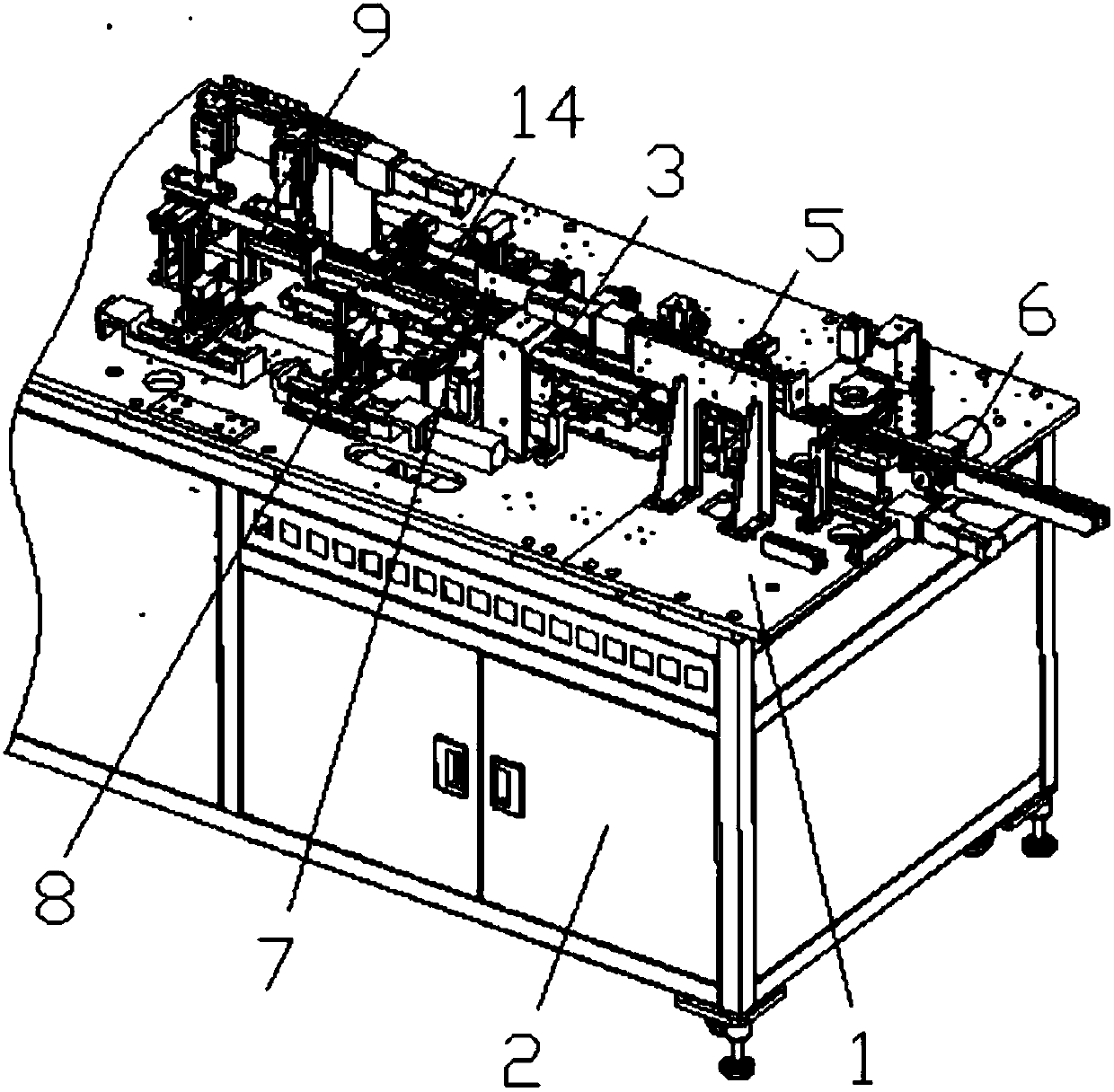

An automatic layout equipment for semiconductor patch welding

ActiveCN110381717BContinuous automatic feedingImprove efficiencyElectrical componentsProcess engineeringMechanical engineering

The invention discloses an automatic arrangement device for semiconductor patch welding. The automatic arrangement device is suitable to be used on a circuit board where semiconductor patches are automatically and accurately arranged during welding. The device provided by the invention can automatically identify, place and arrange the semiconductor patches, has the characteristics of high responseand high precision, can continuously operate, and can greatly improve the efficiency. The device employs a modular design, and comprises a circuit board feeding module, a motion module, a semiconductor patch feeding module and a patch taking and placing module, wherein all the modules work in a matched mode, so the use and maintenance are convenient and easy. The patch taking and placing module adopts an adhesive head to stick patches, so static electricity is avoided, the action is stable, the vibration is small, and the patch placing accuracy is kept to the maximum extent.

Owner:台州市黄岩日隆模具厂(普通合伙)

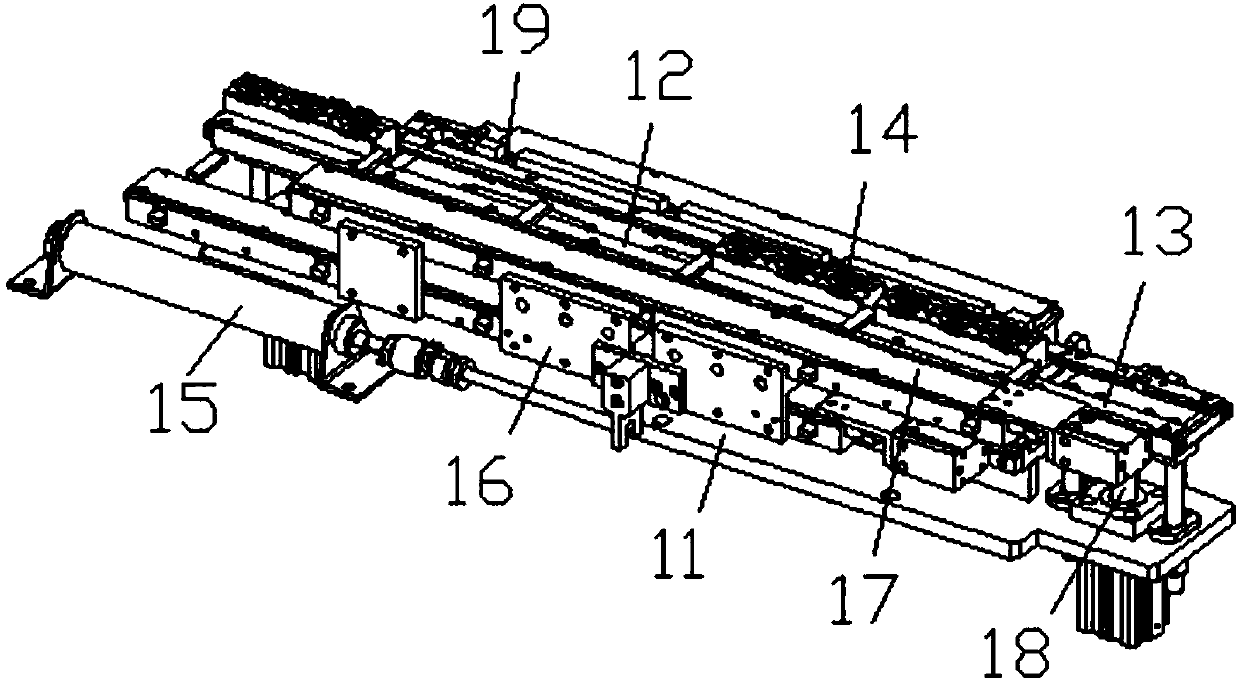

Brake pump pressure releasing cover feeding machine

InactiveCN106697870AContinuous automatic feedingImprove work efficiencyConveyorsConveyor partsEngineeringPump pressure

The invention discloses a brake pump pressure releasing cover feeding machine. The brake pump pressure releasing cover feeding machine comprises a vibration disc installing frame and a rack which are sequentially arranged on the ground. A vibration disc is arranged on the vibration disc installing frame through a vibration disc installing plate. A pressure releasing cover is placed in the vibration disc. A conveying groove is formed in a discharging port of the vibration disc. The part, below the conveying groove, of the rack is provided with a linear vibrator installing base through an installing plate, and the linear vibrator installing base is provided with a linear vibrator. The linear vibrator is fixed to the lower plane of the conveying groove. The part, on the outer side of a discharging port of the conveying groove, of the rack is provided with a feeding mechanism. The part, on one side of the feeding mechanism, of the rack is provided with a discharging mechanism. By means of the above manner, full-automatic operation is achieved in the pressure releasing cover feeding process, manual pressure releasing cover feeding is replaced, continuous and automatic feeding can be achieved, and the work efficiency is improved.

Owner:苏州迈邻物业管理有限公司

Feeding device of brake pump sealing sleeve feeder

InactiveCN108891928ASimple structureLow technical requirementsConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a feeding device of a brake pump sealing sleeve feeding machine, the feeding device of the brake pump sealing sleeve feeding machine comprises a gasket plate, the two ends of the upper plane of the backing plate are respectively fixed with a rotating cylinder mounting plate and a feeding bearing seat mounting plate perpendicular to the rotating cylinder mounting plate and the feeding bearing seat mounting plate by reinforcing ribs, A surface of that mount plate of the rotary cylinder facing the load bearing housing mount plate is fixed with a transverse rotary cylinder,the turntable of the rotary cylinder faces the loading bearing housing mounting plate, A rotary cylinder connecting plate is fixed on a rotary table of the rotary cylinder, a loading bearing seat mounting plate facing the rotary cylinder connecting plate is sequentially fixed with a lifting cylinder fixing seat and a lifting linear guide rail from top to bottom, the lifting linear guide rail is longitudinally arranged, and a lifting linear guide rail connecting plate is fixed on a slider of the lifting linear guide rail. The invention has the advantages of simple structure, fully automatic operation in the feeding process and continuous automatic feeding, and greatly reduces the technical requirements for the operators.

Owner:SUZHOU GUANHAOSI PRECISION MACHINERY CO LTD

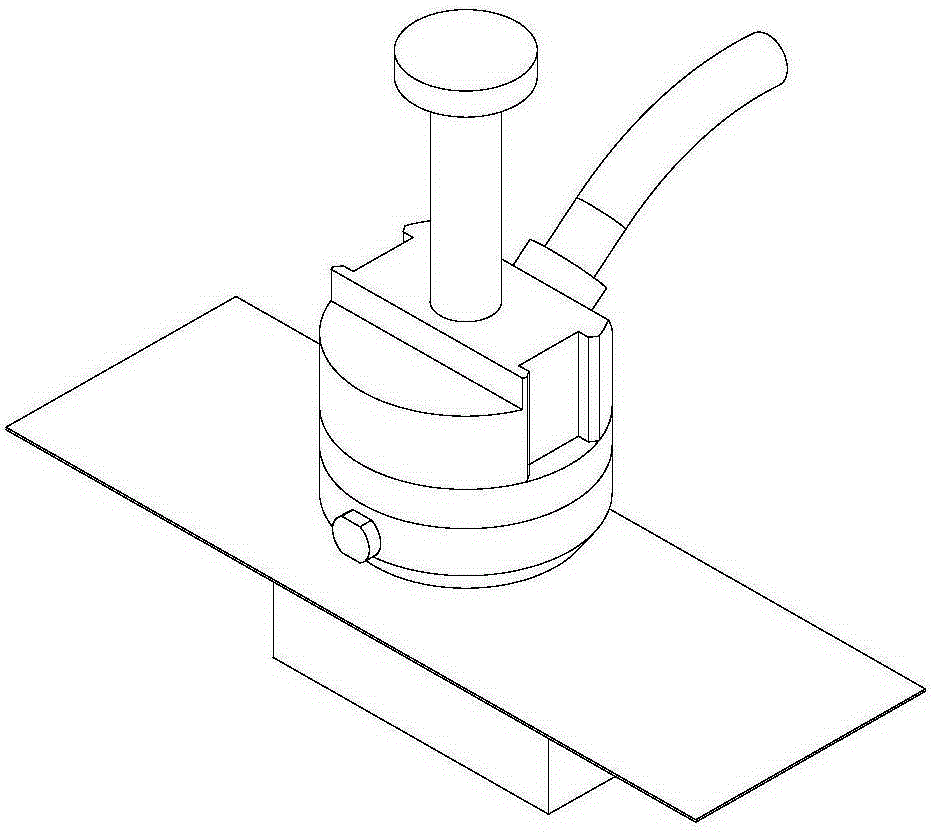

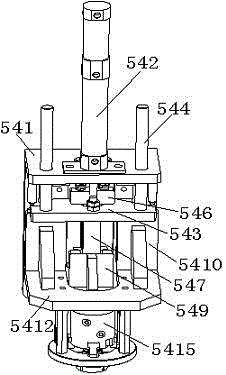

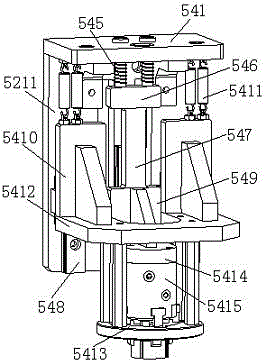

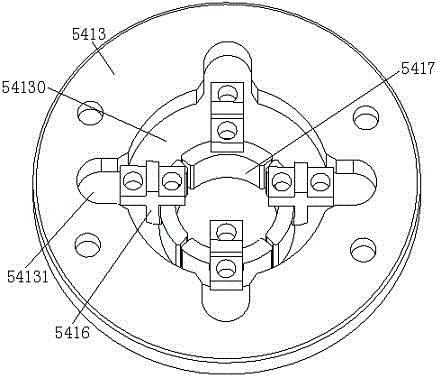

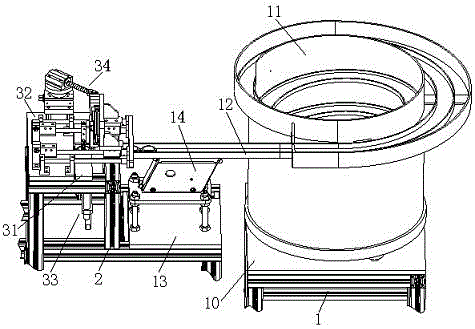

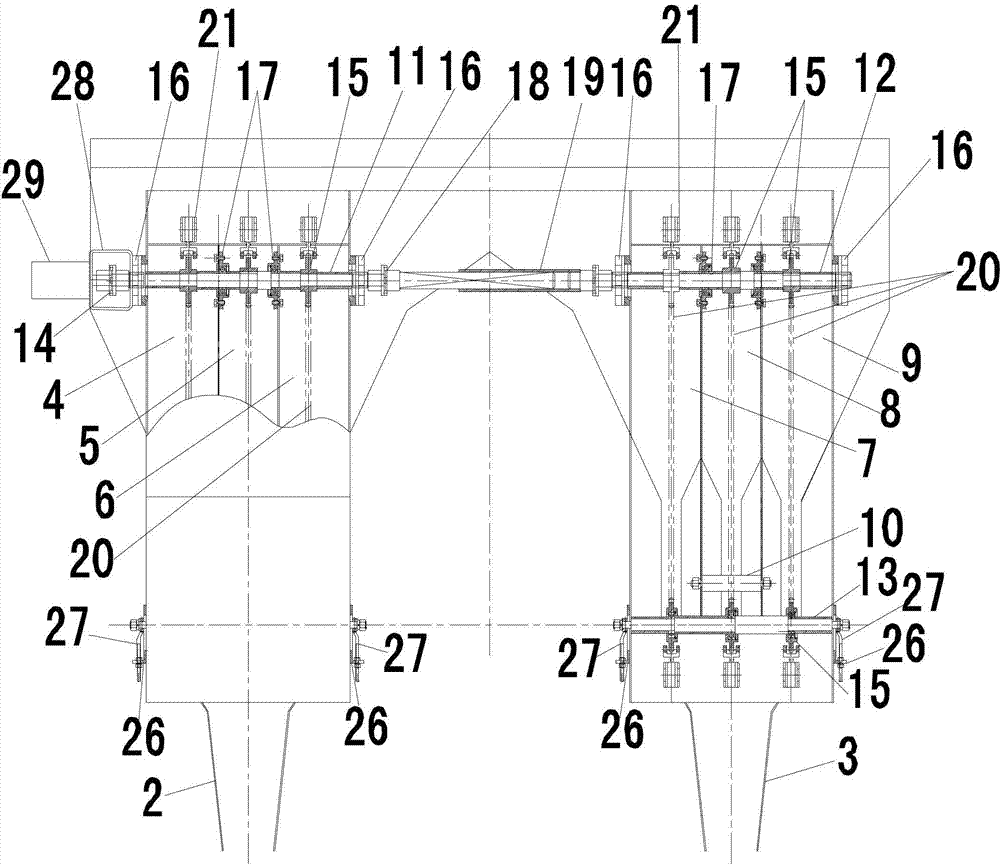

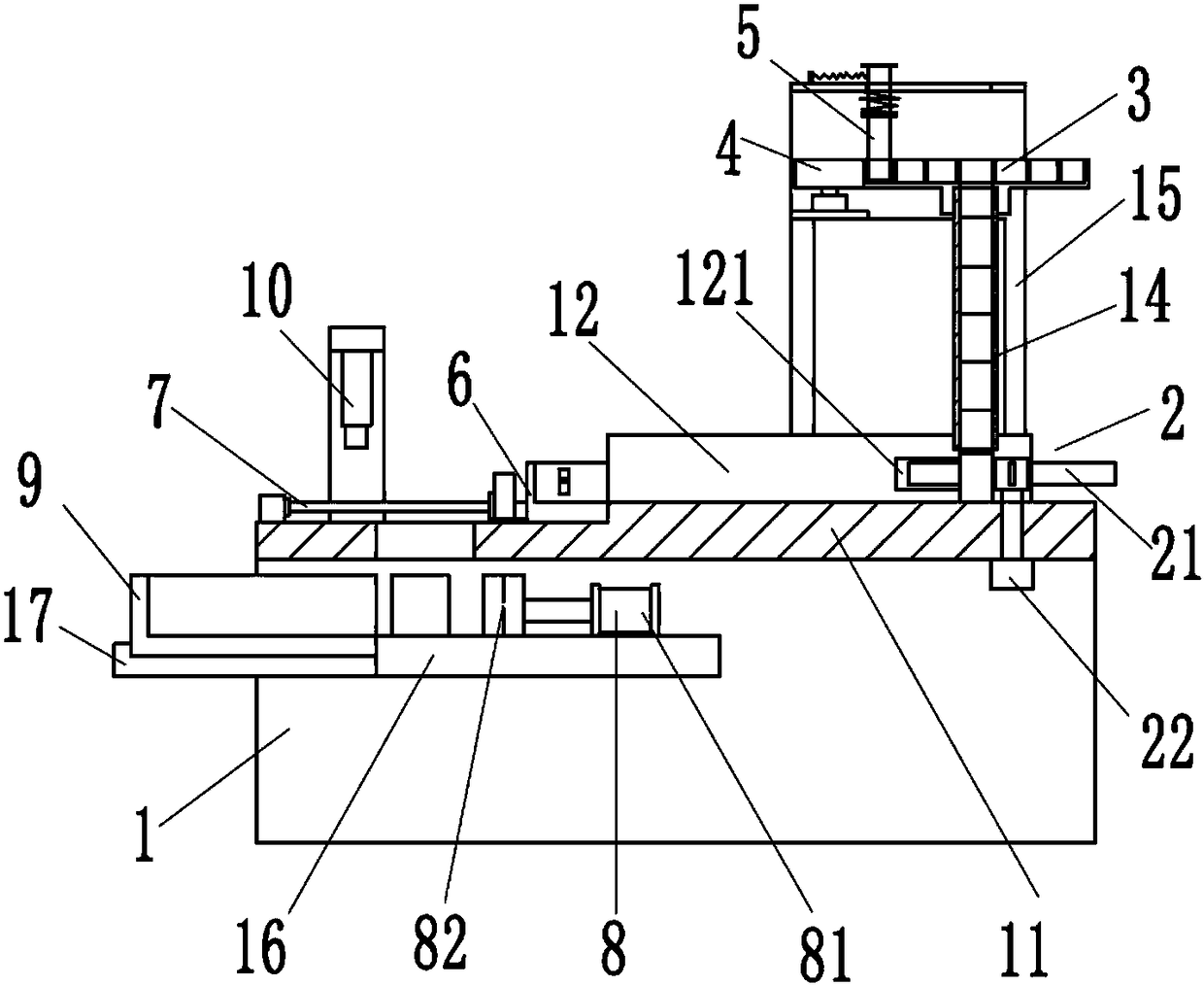

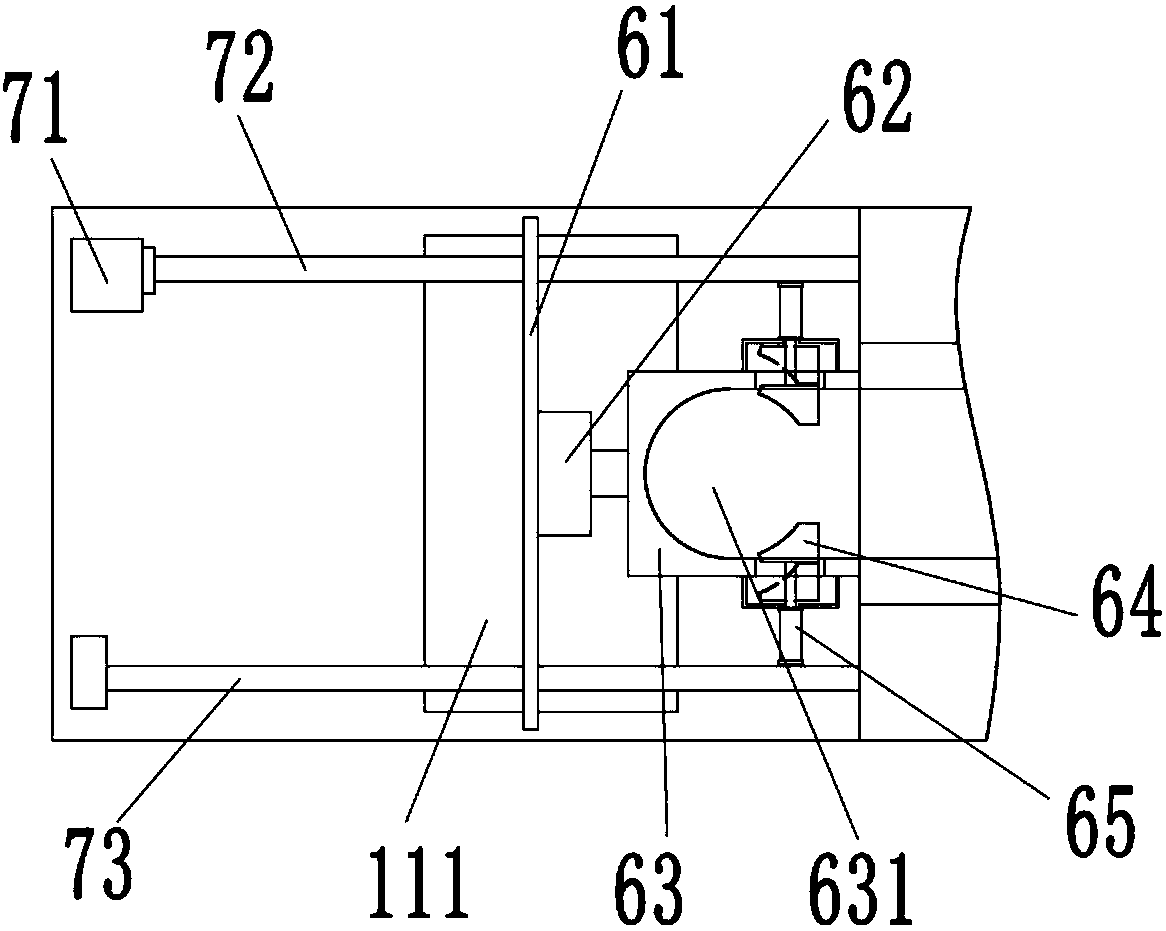

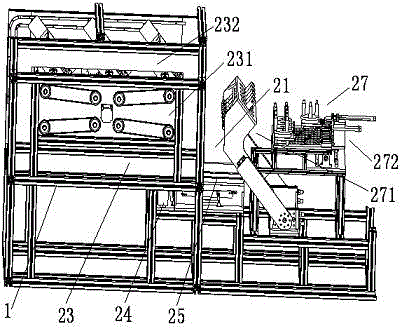

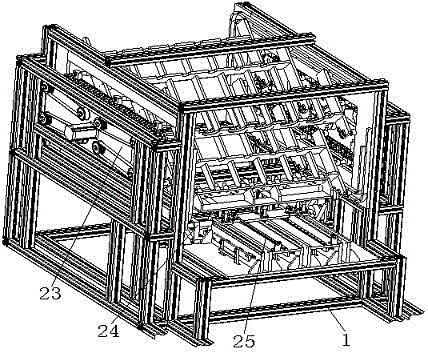

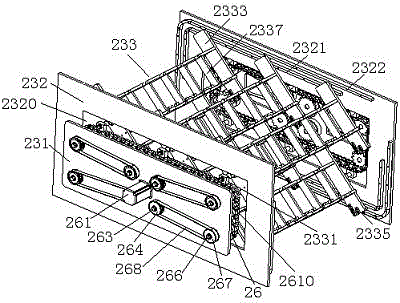

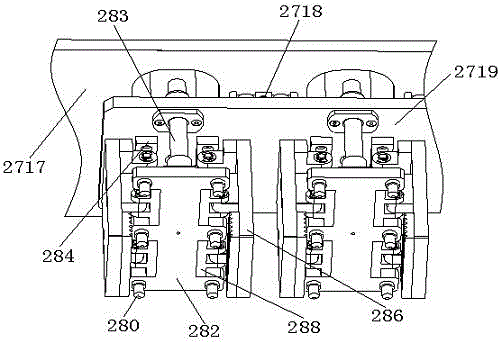

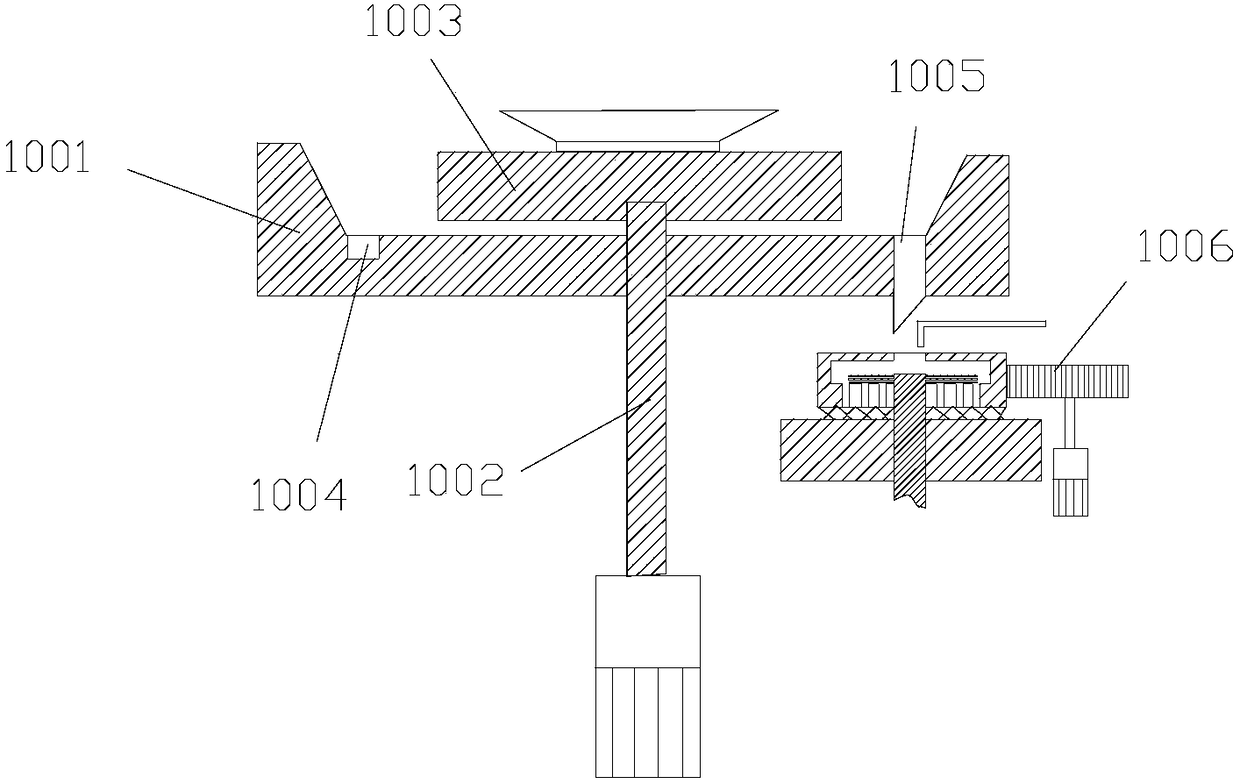

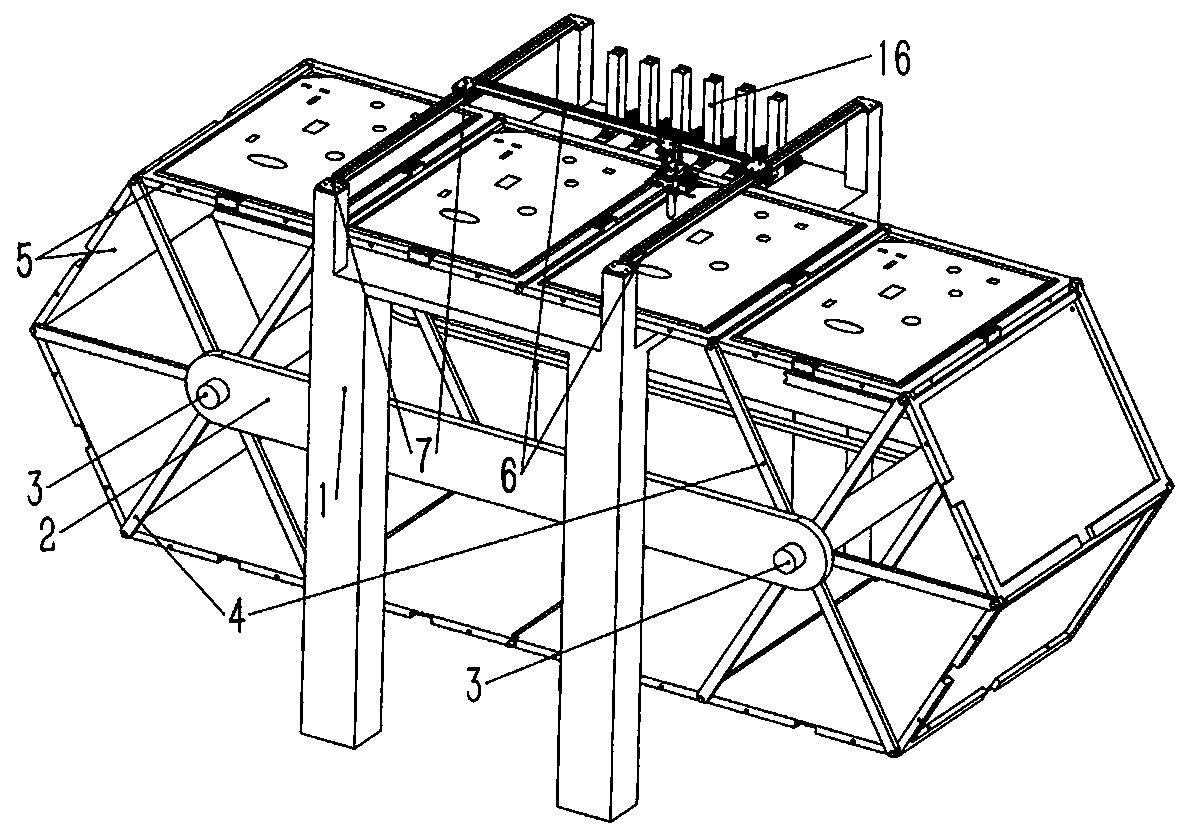

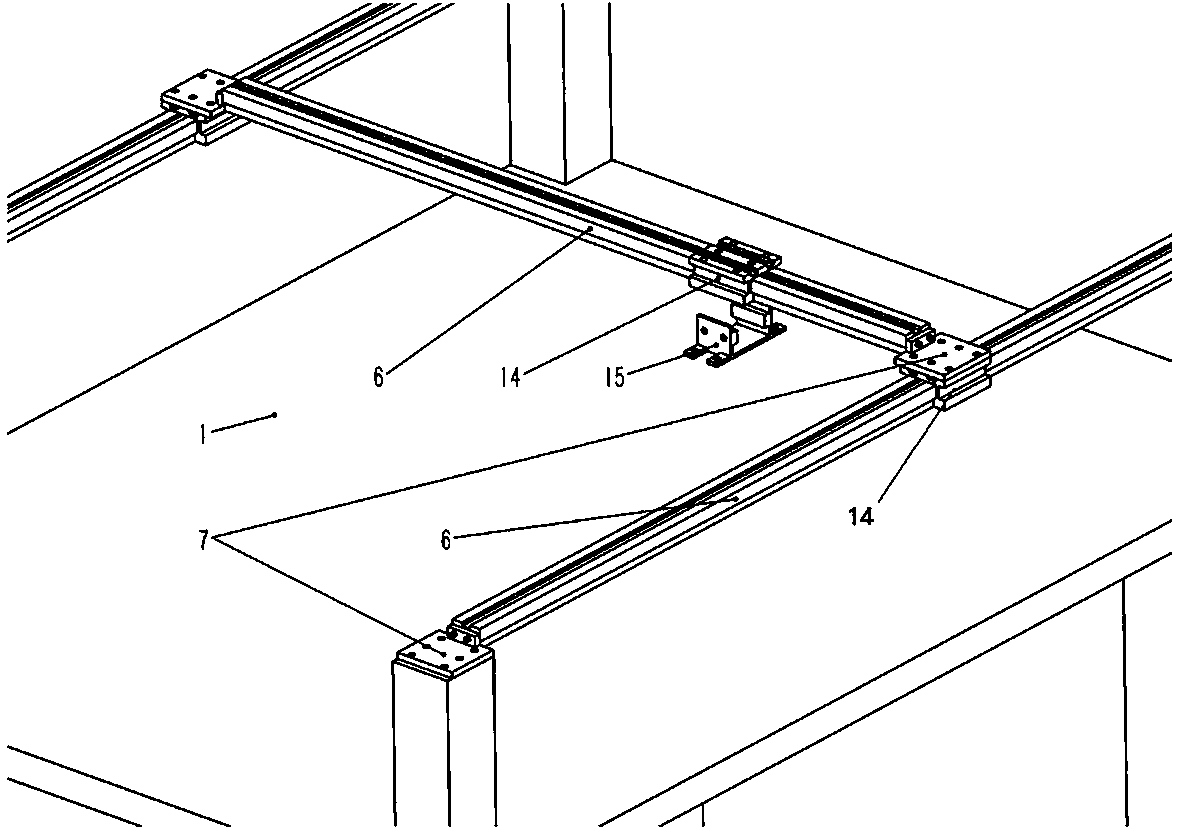

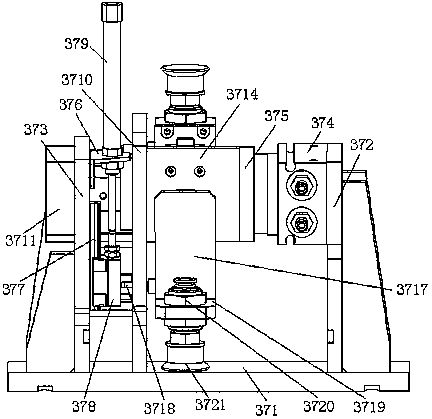

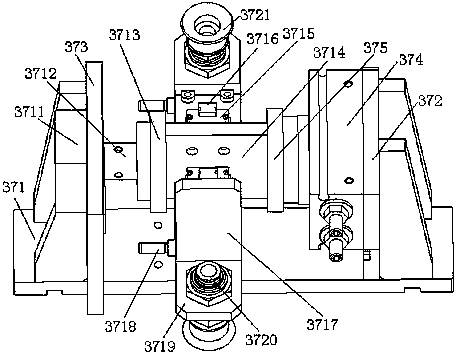

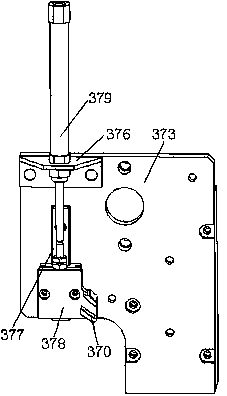

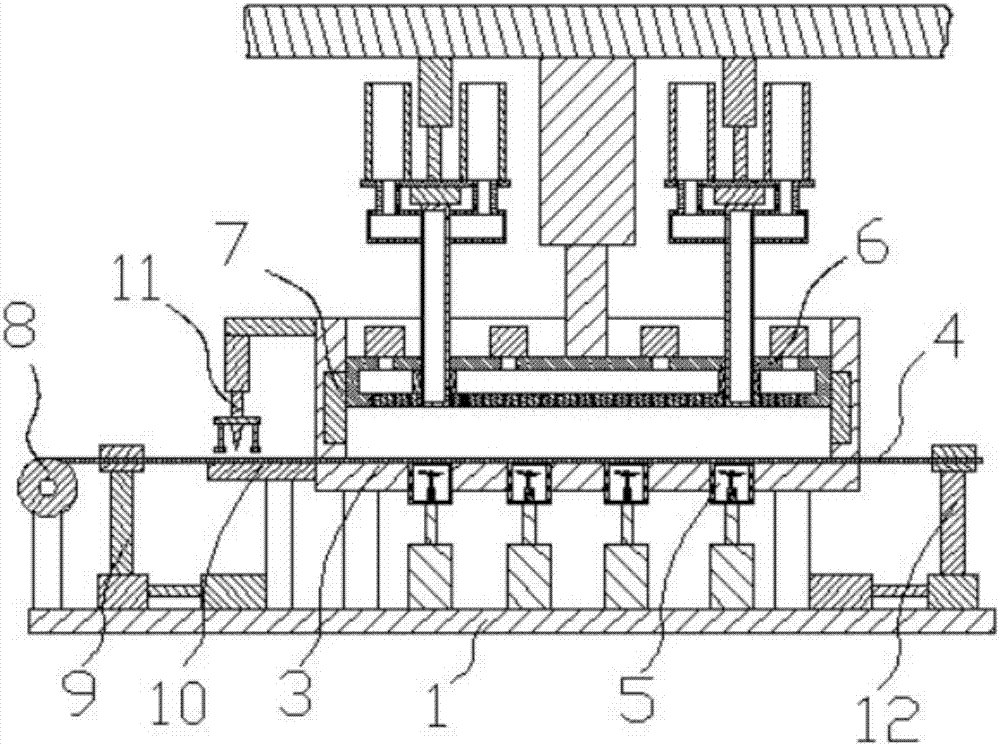

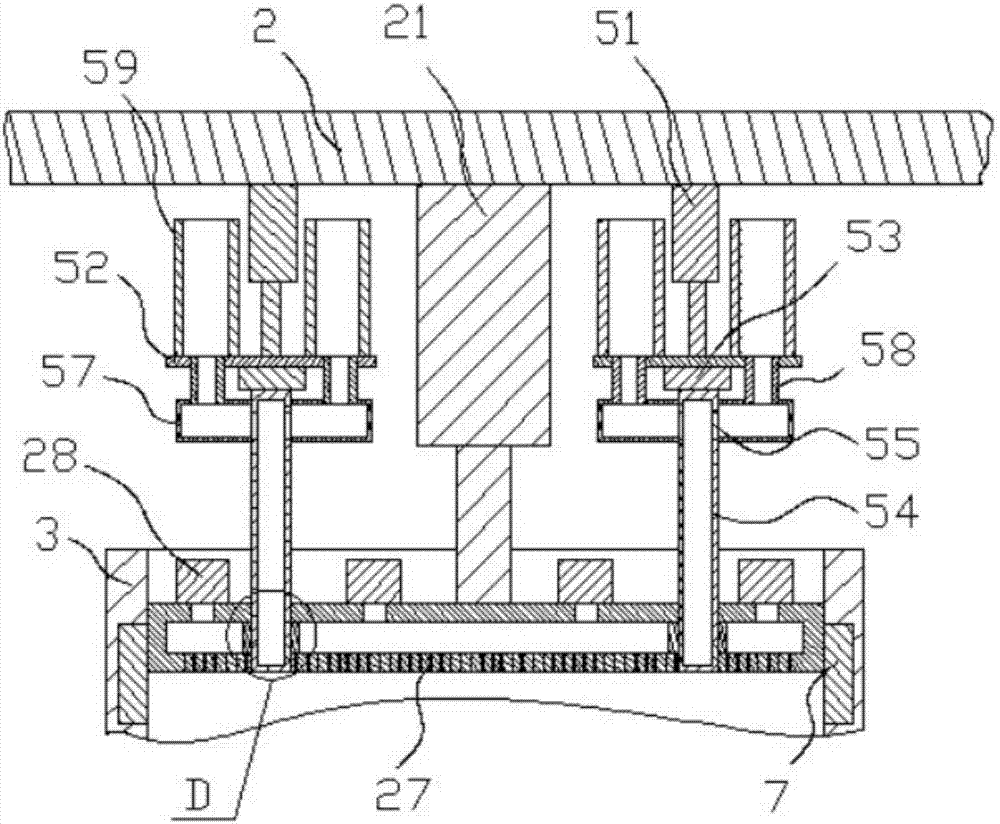

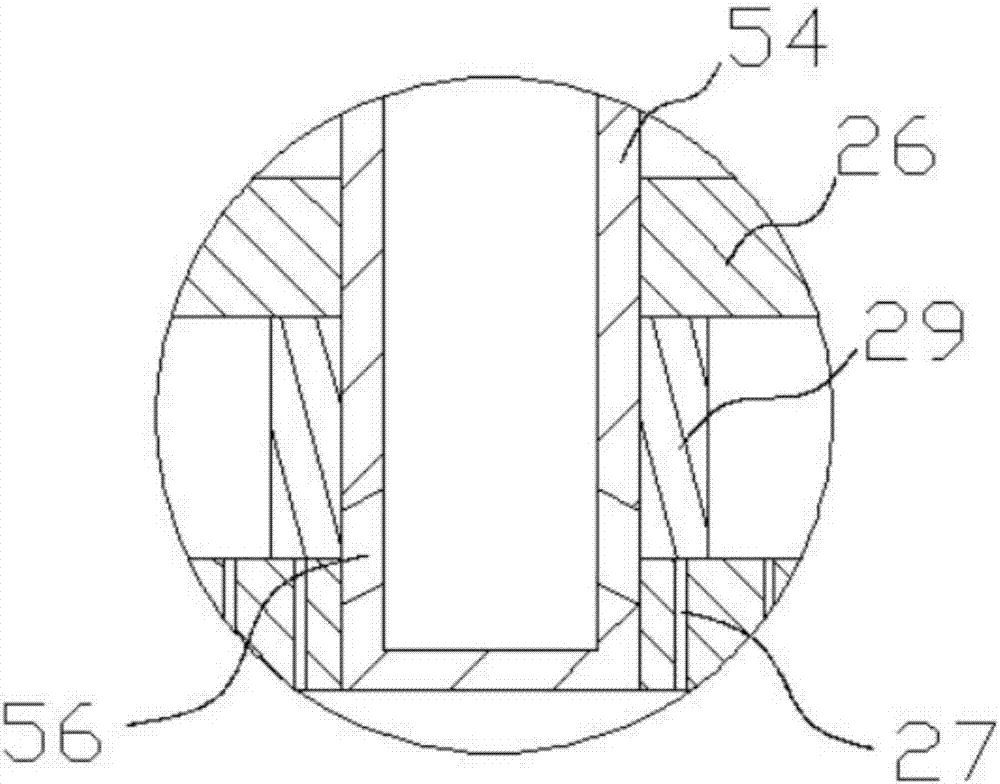

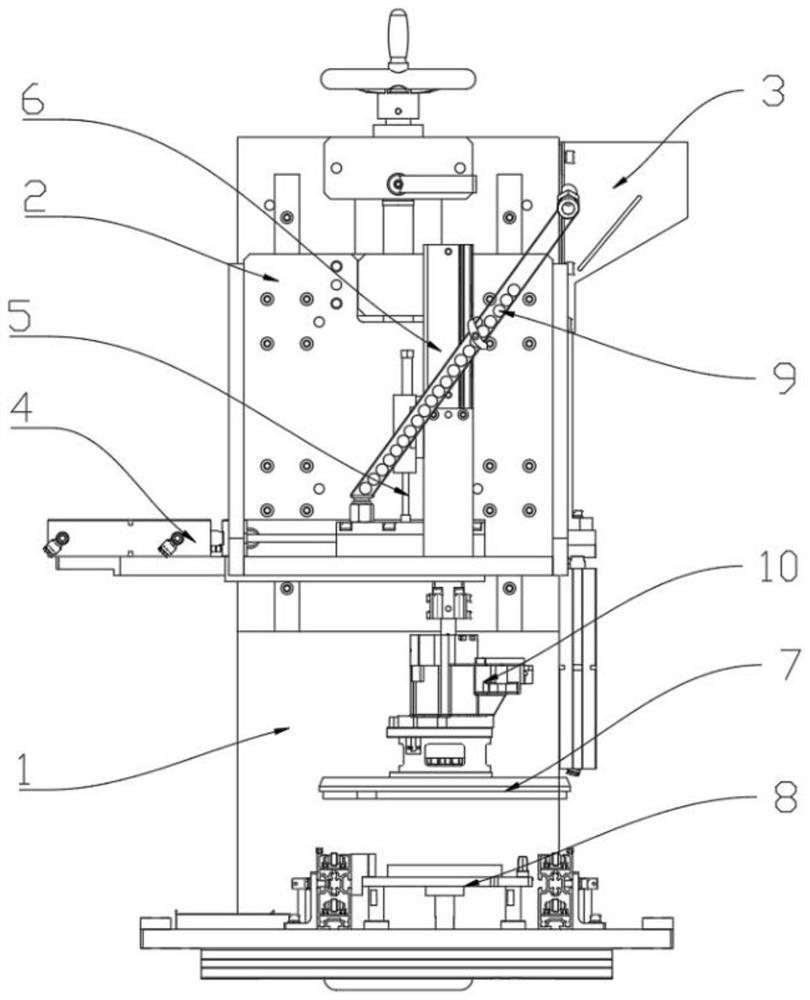

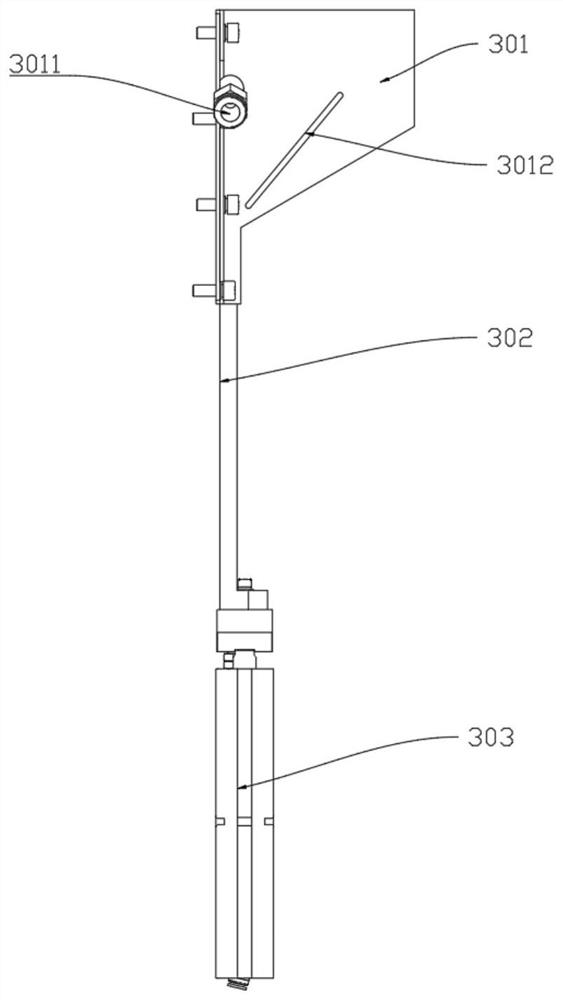

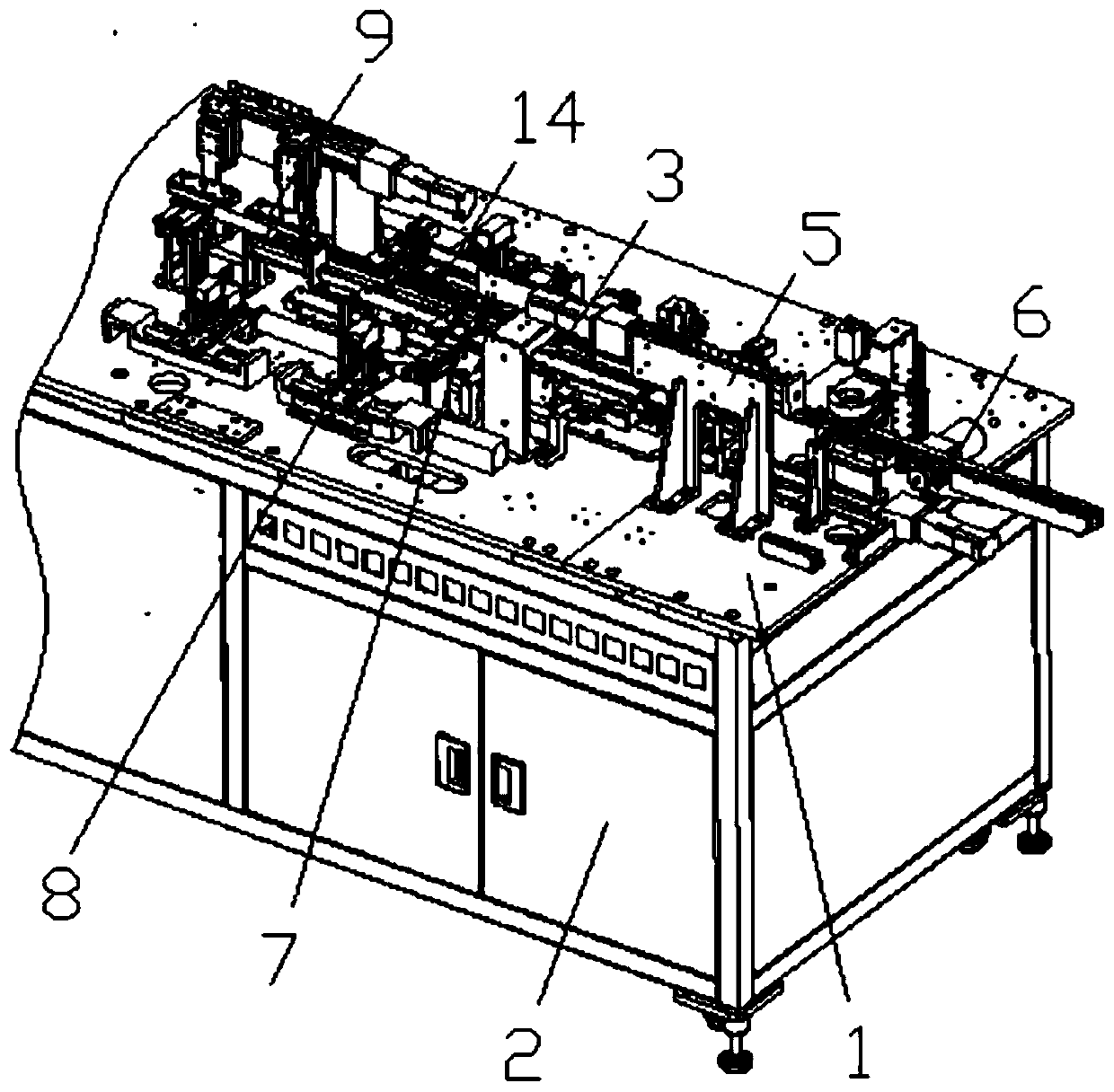

A magnetic tile assembly mechanism for a micro-motor stator

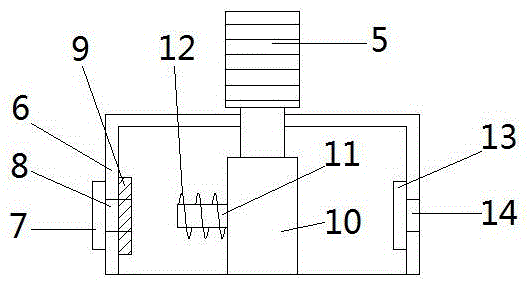

ActiveCN106602803BImprove assembly efficiencySimple structureManufacturing stator/rotor bodiesDistribution controlIntegrated operations

The invention relates to a micromotor stator magnetic tile assembly mechanism, which comprises a rack and a power distribution control cabinet. The rack is provided with a conveying trough cooperated with a housing. The rack is provided with a magnetic tile assembly device, a front iron wire press-in device and a magnetizing device, which are cooperated with a product in the conveying trough, in sequence from the right to left. The front portion of the front iron wire press-in device is cooperated by a front iron wire conveying device. The magnetic tile assembly device comprises a magnetic tile assembly frame arranged on the rack. The left and right two sides of the magnetic tile assembly frame are respectively provided with a magnetic tile pushing device, the front side thereof is provided with a housing movable device, the back side thereof is cooperated by a back iron wire conveying device, and the lower portion thereof is provided with a push-in device. The micromotor stator magnetic tile assembly mechanism is provided with the conveying trough cooperated with the housing; the rack is provided with the back iron wire conveying device, the magnetic tile assembly device, the front iron wire conveying device, the front iron wire press-in device and the magnetizing device, which are cooperated with a stator in the conveying trough, in sequence, thereby realizing integrated operation and improving magnetic tile assembly efficiency.

Owner:JIANGSU HONGBO MACHINERY MFG

Tea brick molding machine convenient for material feeding

InactiveCN107980937AEasy loadingRealize the pressing effectPre-extraction tea treatmentBrickMolding machine

The invention relates to a tea brick molding machine convenient for material feeding. The tea brick molding machine comprises an upper rack and a lower rack, wherein a molding frame is arranged on thelower rack; a molding device matched with the molding frame is arranged on the upper rack; the molding device comprises a molding lifting cylinder; a molding block is connected below the molding lifting cylinder; feeding lifting cylinders are arranged on two sides of the lower part of the upper rack; feeding lifting bases are arranged below the feeding lifting cylinders; feeding motors are arranged below the feeding lifting bases; feeding cylinders which can penetrate through the molding blocks are connected below the feeding motors; sealing covers are arranged at both the upper ends and thelower ends of the feeding cylinders; feeding holes are formed in the upper parts of the side surfaces of the feeding cylinders; discharge holes are formed in the lower parts of the side surfaces of the feeding cylinders. As the feeding cylinders which can be rotated and lifted up and down penetrate through the molding block in match, the feeding holes are formed in the upper parts of the feeding cylinders, and the discharge holes are formed in the lower parts of the feeding cylinders, material discharge can be achieved through the height differences of the feeding cylinders and the molding blocks, great convenience is brought to tea leaf feeding, and the whole molding efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

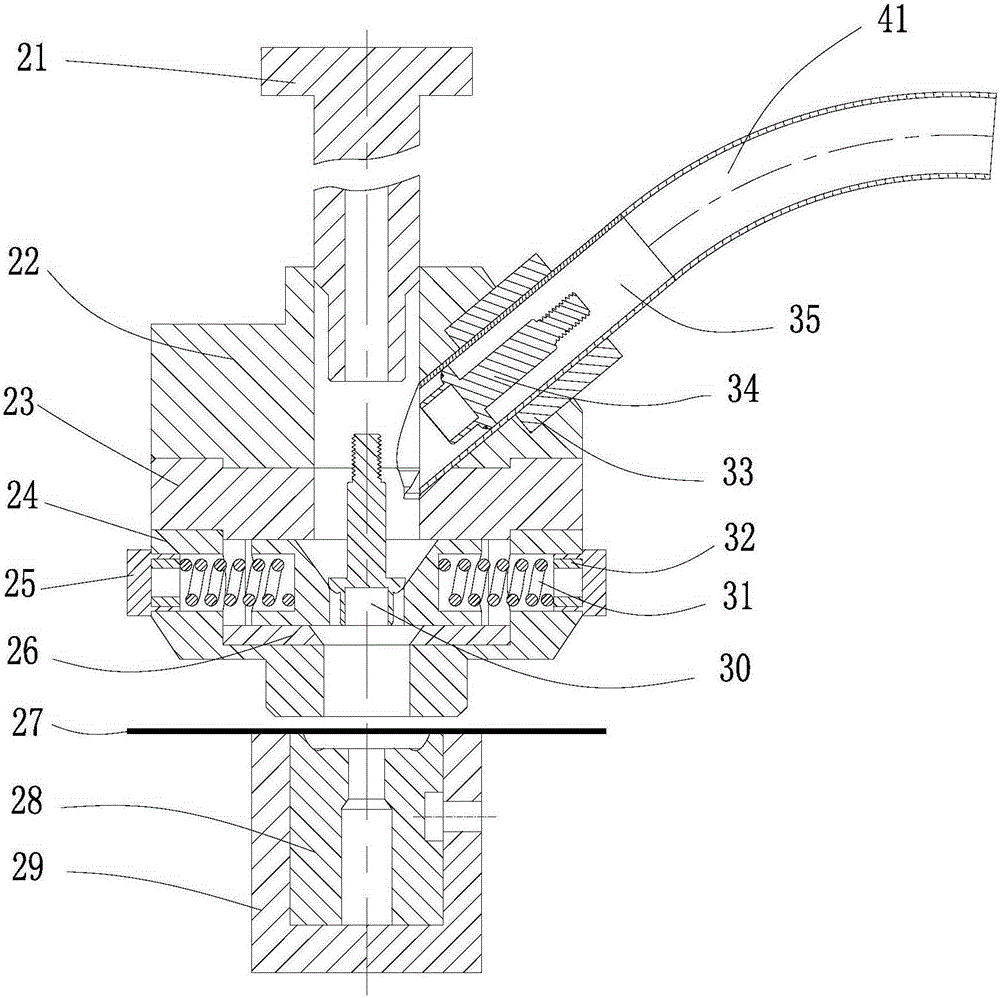

Automatic assembling device for starter steel balls

PendingCN113427235AAdjustable embedding depthSimple structureMetal working apparatusButt jointEngineering

The invention relates to an automatic assembling device for starter steel balls. The automatic assembling device for the starter steel balls comprises a base, a height adjusting mechanism, a feeding mechanism, a material pushing mechanism, a press fitting mechanism and a positioning base, the height adjusting mechanism is arranged at the top end of the base in a sliding mode, the feeding mechanism is fixedly arranged on the side face of the base, the material pushing mechanism and the press fitting mechanism are arranged at the lower end of the height adjusting mechanism, the discharging end of the feeding mechanism is in butt joint with the material pushing mechanism, the material pushing mechanism is arranged below the press fitting mechanism, a steel ball detection unit is arranged in the material pushing mechanism, and the positioning base is arranged right opposite to the lower portion of the press fitting mechanism and used for carrying starters to be assembled. The automatic assembling device for the starter steel balls can automatically carry out assembling on the steel balls of the starters, is suitable for various starters with different heights and sizes, and is wide in applicability; and whether neglected assembly exists or not is detected during assembly, so that the assembly efficiency and accuracy are improved.

Owner:DONGFENG AUTOMOBILE ELECTRONICS

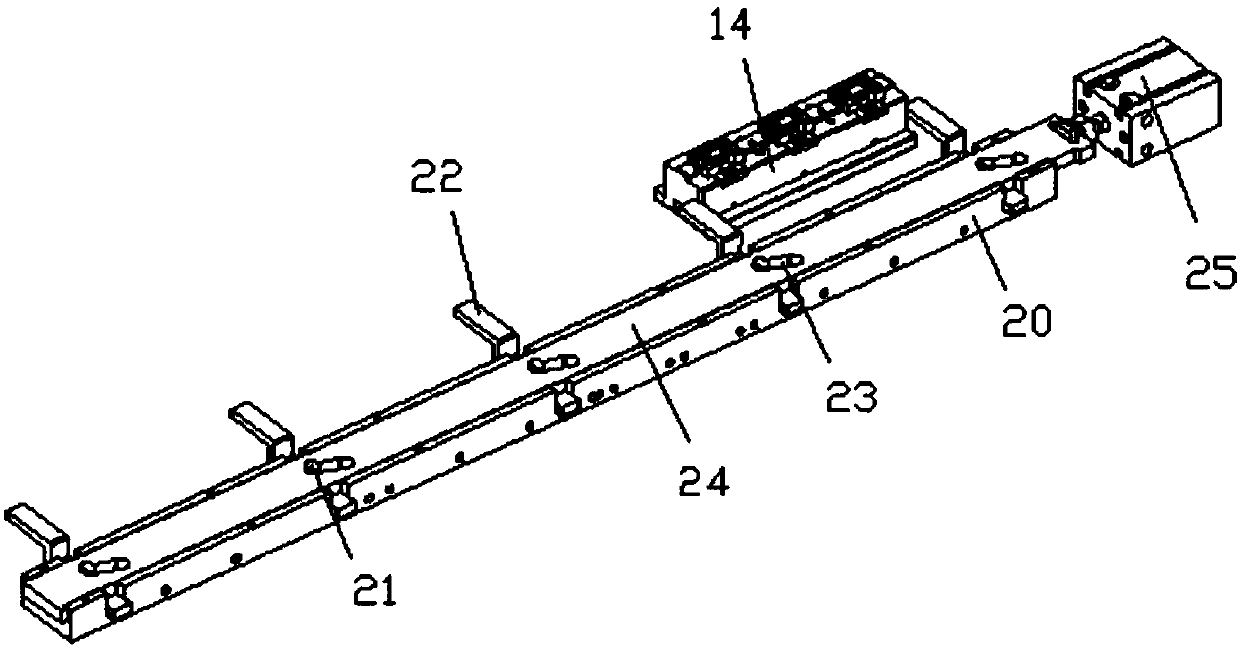

Loading module of brake pump sealing ring loading machine

InactiveCN106736392ANovel structureContinuous automatic feedingMetal working apparatusPulp and paper industry

The invention discloses a loading module of a brake pump sealing ring loading machine. The loading module of the brake pump sealing ring loading machine comprises a loading mounting plate; two first fixed column mounting bases, two second fixed column mounting bases and two guide shaft mounting bases are fixed on the upper plane of the loading mounting plate; the two second fixed column mounting bases are respectively corresponding to the two first fixed column mounting bases; the two guide shaft mounting bases are positioned between the two first fixed column mounting bases; the two first fixed column mounting bases are respectively fixed with one fixed columns; the other ends of the two fixed columns penetrate through the corresponding second fixed column mounting bases to fix with guide column mounting plates through oil sleeves; and guide shafts are respectively fixed between opposite inner side surfaces of the guide column mounting plates and the two guide shaft mounting bases. Through the mode, the loading module of the brake pump sealing ring loading machine is simple and novel in structure, realizes full-automatic operation in the loading process, replaces manual workpiece loading, and can continuously and automatically load materials.

Owner:苏州迈邻物业管理有限公司

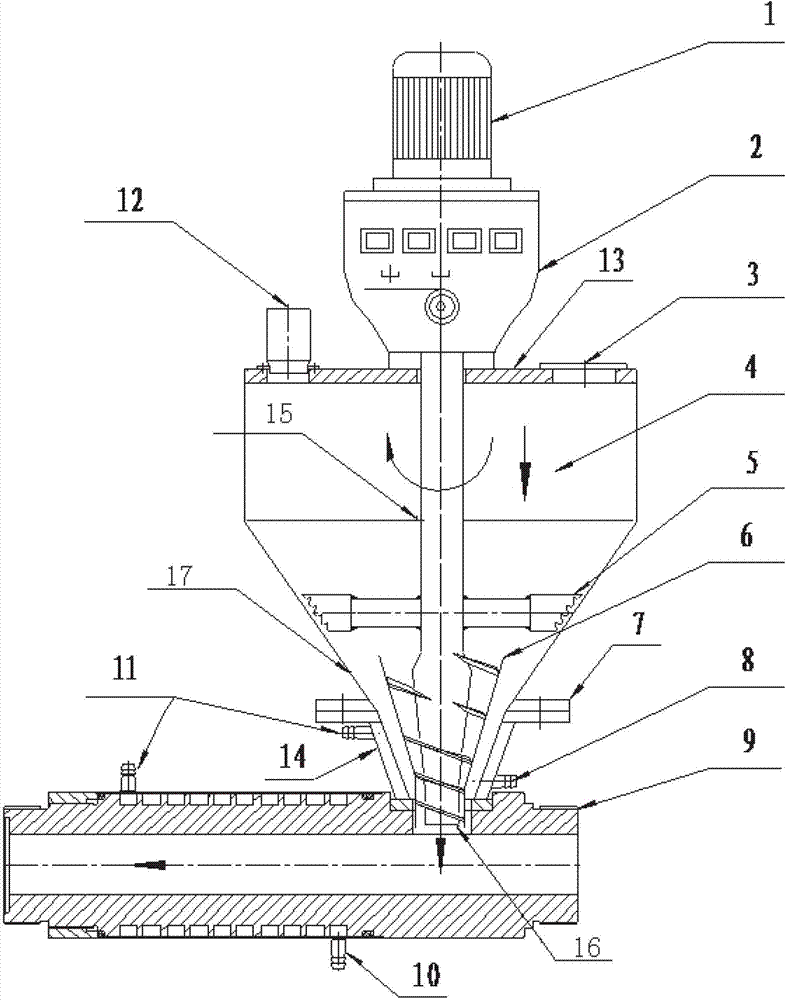

Mixed fat micellar material forced continuous feeding machine

ActiveCN102964187BSmooth feedingContinuous automatic feedingExplosive working-up apparatusHelical bladeMolding machine

A continuous forced feeding machine for mixed fat micelles proposed by the present invention includes a radially connected feeding container and a reducer driven by a motor (1), and a feeding screw shaft (15) connected to the rotating shaft of the reducer is fixed vertically. The joint-defense bridging mixing blade (5) extends vertically into the feeding port (16) of the screw forming machine (9), and on the circumference of the rod body at the tapered end of the feeding screw shaft, there are three layers consisting of upper, middle and lower layers. The feeding screw spinning feeder (6) composed of feeding screw spinning blades of different structures, and the middle layer screw blade (19) with a radial opening splitter groove (21), while allowing the material to start feeding into the screw feeding state, While letting part of the material return upward through the opening of the vane splitter groove, the material is exhausted and diverted, and the lower continuous spiral blade continuously feeds the material to the feed port of the screw press. The invention safely and stably feeds materials into the screw press machine uniformly, without agglomeration, without material blocking, and evenly feeds materials. The quality stability of the molding process of the mixed fat blasting charge is improved.

Owner:LUZHOU NORTH CHEM IND

Machining automatic conveying device

The invention relates to the correlation technical field of machining, in particular to a machining automatic conveying device. The machining automatic conveying device comprises a containing cavity.The containing cavity is fixed to a base through a support, a buffer cavity is formed in one side of the lower end of the containing cavity, an upper rack plate and a lower rack plate are arranged atthe upper end and the lower end of the buffer cavity, the motion directions of the upper rack plate and the lower rack plate are opposite, a conveying chain assembly mounted on the support is arrangedbelow the containing cavity, and multiple arc-shaped jaws are mounted on the conveying chain assembly at equal intervals. The design is novel, when the arranged arc-shaped jaws move to the upper endof the conveying chain assembly, the arc-shaped jaws abut against a drive plate fixed to the lower rack plate, when the arc-shaped jaws continuously move, the drive plate drives the lower rack plate to be opened, a columnar part falls into the arc-shaped jaws, under the blocking effect of the upper rack plate, the other columnar parts are prevented from falling out, thus, continuous automatic feeding is achieved, and the automation degree is high.

Owner:XIAN UNIV OF POSTS & TELECOMM

A stator magnetic tile assembly mechanism capable of accurately magnetizing

ActiveCN109167493AImprove assembly efficiencySimple structureManufacturing stator/rotor bodiesDistribution controlIntegrated operations

The invention relates to a stator magnetic tile assembly mechanism capable of accurately magnetizing, It consists of a rack and a distribution control box, the machine frame is provided with a conveying groove which is matched with the shell, A magnetic tile assemble device is sequentially arranged on that frame from the right to the left and cooperate with products in the conveying groove, A front wire press-in device and a magnetizing device, the front part of the front iron wire press-in device is matched with a front iron wire conveying device, the magnetic tile assembly device comprises amagnetic tile assembly rack arranged on a rack, the left and right sides of the magnetic tile assembly frame are provided with magnetic tile propulsion devices, A housing movable device is arrange onthat front side, A rear wire conveyor is fit on that rear side, The lower part is provided with an ejection device, the invention is provided with a conveying groove matched with the shell, and a rear iron wire conveying device matched with the stator in the conveying groove, a magnetic tile assembling device, a front iron wire conveying device, a front iron wire pressing device and a magnetizingdevice are sequentially arranged on the frame, thereby realizing the integrated operation and improving the efficiency of the magnetic tile assembling.

Owner:安徽明亮面业股份有限公司

A kind of interface detection machine which is convenient for picking and unloading materials

ActiveCN107826631BAvoid misalignmentImprove detection accuracyMeasurement devicesConveyor partsPower flowDistribution control

The invention relates to a feeding mechanism of a connector detection machine. The feeding mechanism of the connector detection machine comprises a machine frame, a power distribution control box anda conveying device. The conveying device comprises a conveying base. A conveying groove and taking and placing grooves are formed in the conveying base, and a feeding device is further arranged on theconveying base. A current detection device, a camera detection device and a blanking mechanical hand are arranged on the machine frame. Each carrier comprises a carrier body which cooperates with theconveying groove and the taking and placing grooves. A fixing material carrying block which cooperates with a product body is arranged on the top of each carrier body. A clamping moving block is arranged at the bottom of the interior of each carrier body, a reset spring hole is formed in the front end of each clamping moving block, and each clamping reset spring cooperates with the correspondingreset spring hole. Two clamping moving grooves which are inwards inclined are formed in each clamping moving block and cooperates with clamping moving rods, and clamping blocks are arranged on the tops of the clamping moving rods. According to the feeding mechanism of the connector detection machine, the conveying device and the carriers cooperate with each other and are adopted to achieve continuous conveying detection of products, and therefore the situations of dislocation and false detection in the detection process are avoided, the detection accuracy is improved, and the products are conveniently taken and placed.

Owner:东莞市银天新能源有限公司

Food processing mixer with automatic feeding mechanism

PendingCN107981399AUniform automatic feedingFacilitate post-package handlingFood shapingPropellerAir pollution

The invention discloses a food processing mixer with an automatic feeding mechanism. The food processing mixer with the automatic feeding mechanism comprises a machine body, wherein a material elevator is vertically arranged on the left side of the machine body; a feed hopper is arranged at the left end of a feed port in the lower side of the material elevator; a weight sensor is arranged on the lower side of the feed hopper; a material pushing plate is arranged on the left side of the inner part of the feed hopper; the left side of the material pushing plate is connected with a piston rod ofa first hydraulic cylinder; the weight sensor is connected with the first hydraulic cylinder through a controller; a material baffling plate is arranged on the right side of the feed hopper. The foodprocessing mixer with the automatic feeding mechanism achieves continuous and uniform automatic feeding through the elevator and a screw feed mechanism, has high feeding efficiency, does not need manual operation, saves time and labor and can achieve quantitative feeding; helical ribbon-type stirring propellers and transverse stirring blades are used for stirring raw materials of food, so that thestirring effect is good, the stirring efficiency is high, and raw materials are sufficiently and uniformly stirred; in addition, dust can be effectively avoided from blocking key parts of the machine, the environment is protected and air pollution is avoided.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com