An automatic layout equipment for semiconductor patch welding

A patch welding and semiconductor technology, applied in electrical components, electrical components, etc., can solve the problems of tired work, high labor intensity, and high cost of robot patching, and achieve high positioning accuracy, continuous and automatic feeding, and small vibration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

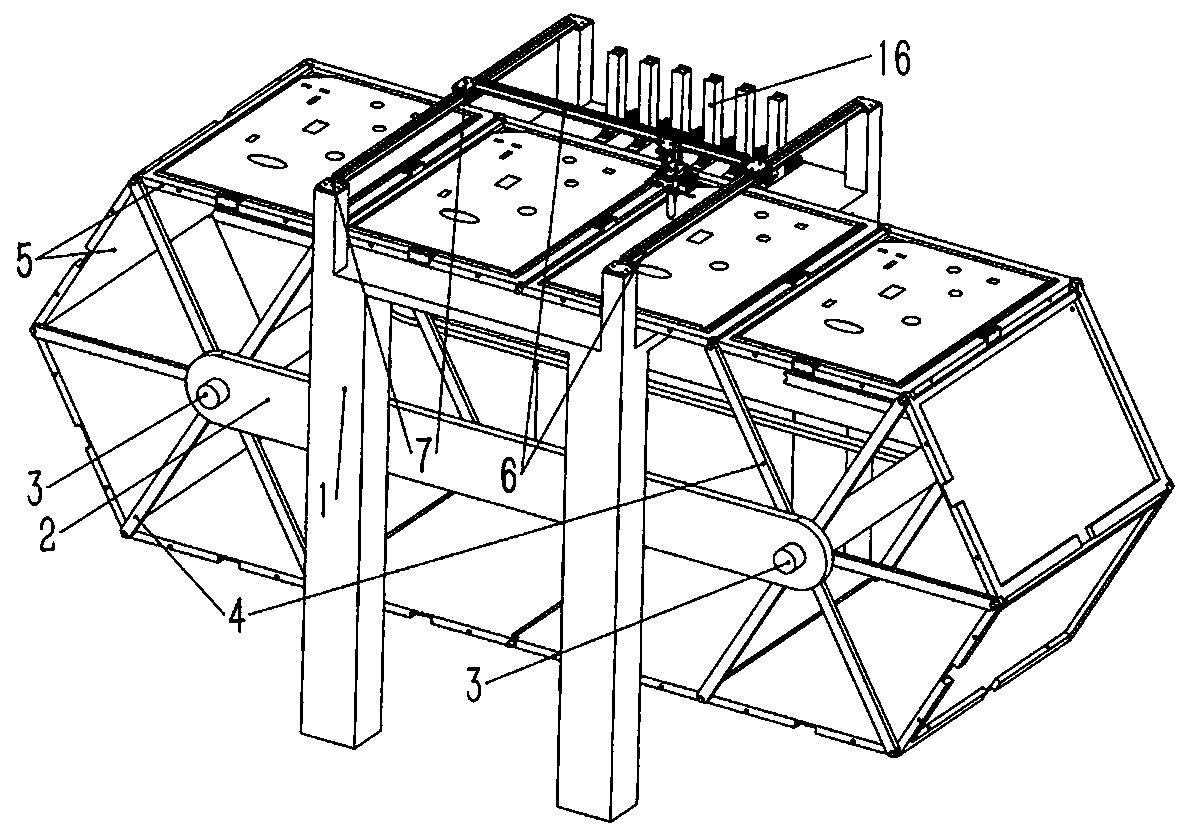

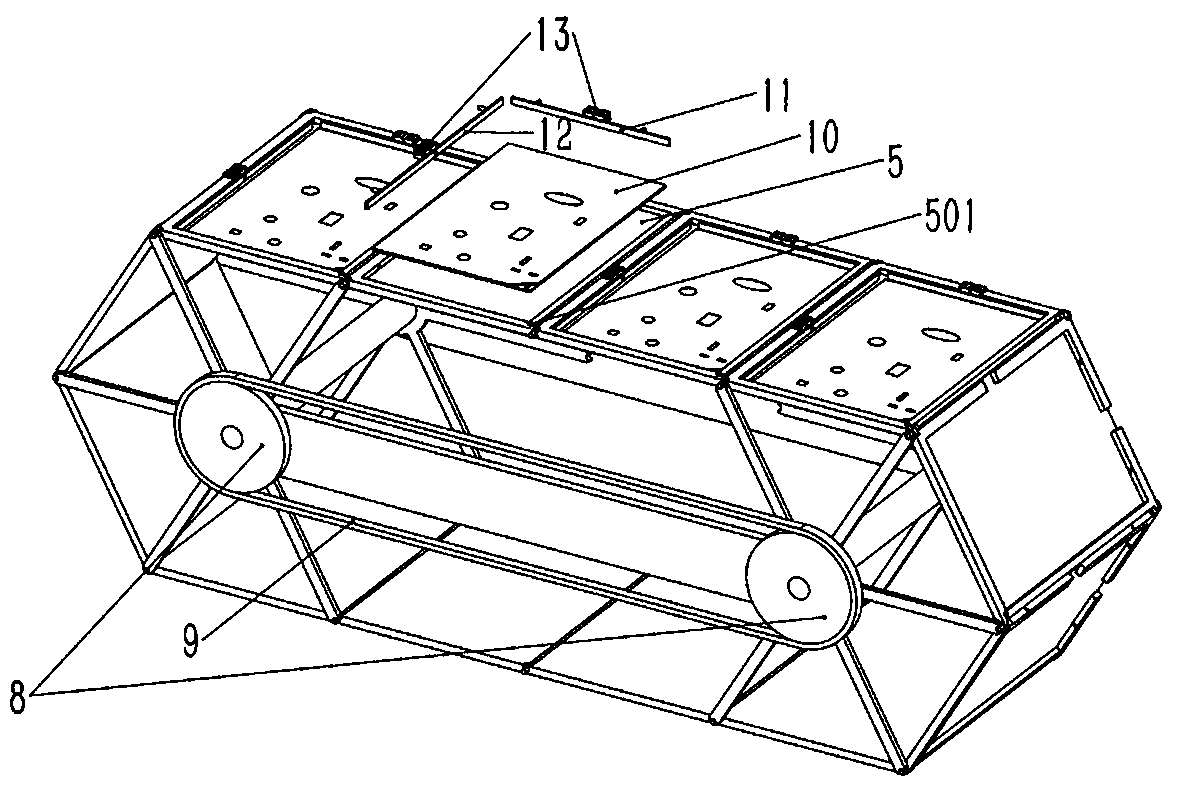

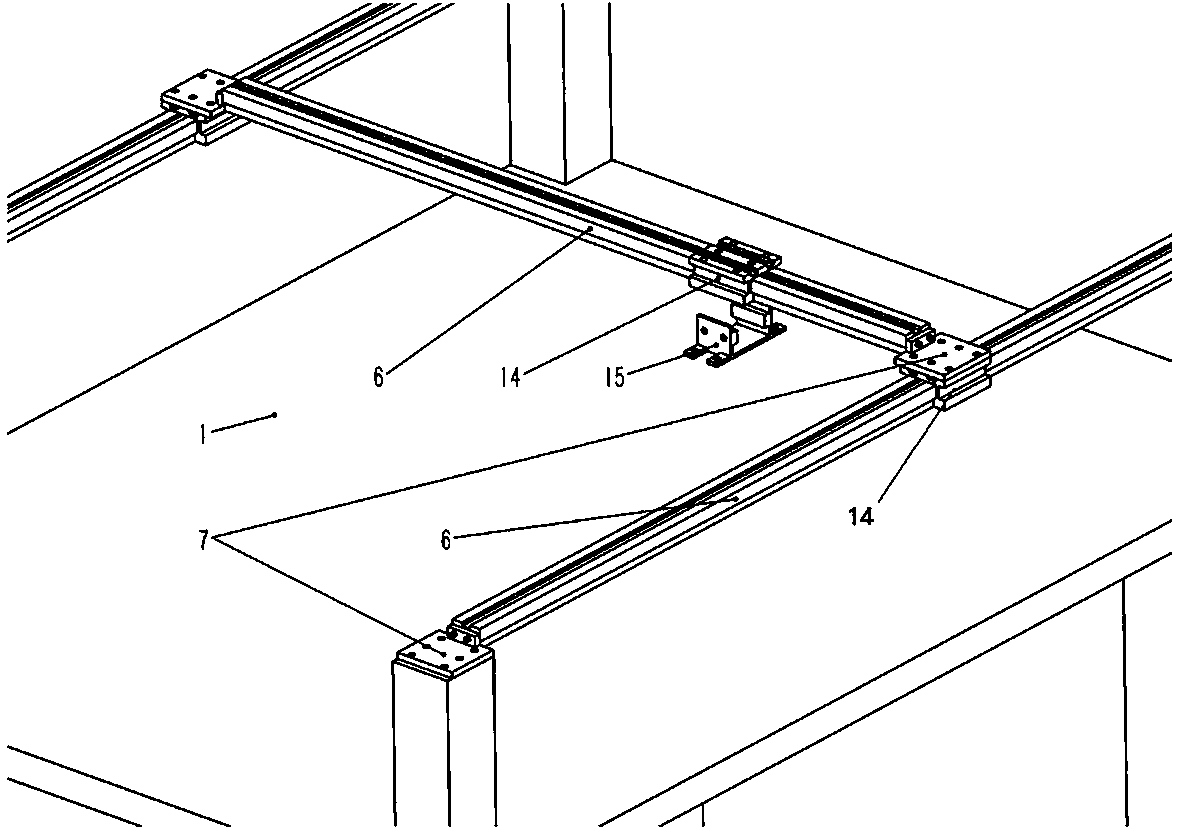

[0021] Example: such as Figure 1 to Figure 6 The semiconductor patch welding automatic layout equipment shown is a semiconductor patch welding automatic layout equipment, including a circuit board feeding module, a translation movement module, a patch feeding module and a patch picking and placing module, and its circuit The board feeding module also includes a chain-driven circular feeding mode, and the translation movement module also includes a screw guide rail-type feed driving mode.

[0022] The circuit board feeding module is designed for circular feeding, and has multiple stations including loading station, patch station, and unloading station, including two fixed plates 2 installed on the frame 1, of which , the rotating shaft 3 is installed on the two fixed plates 2, the bracket 4 is fixedly installed on the rotating shaft 3, the bracket 4 is designed with six arms, each arm has a semicircular groove at the top, and several loading plates 5 pass through the pin shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com